Hydraulic, magnetic & electro-thrust brake systems – AMETEK Electro-Thrust Shoe Brakes User Manual

Page 2

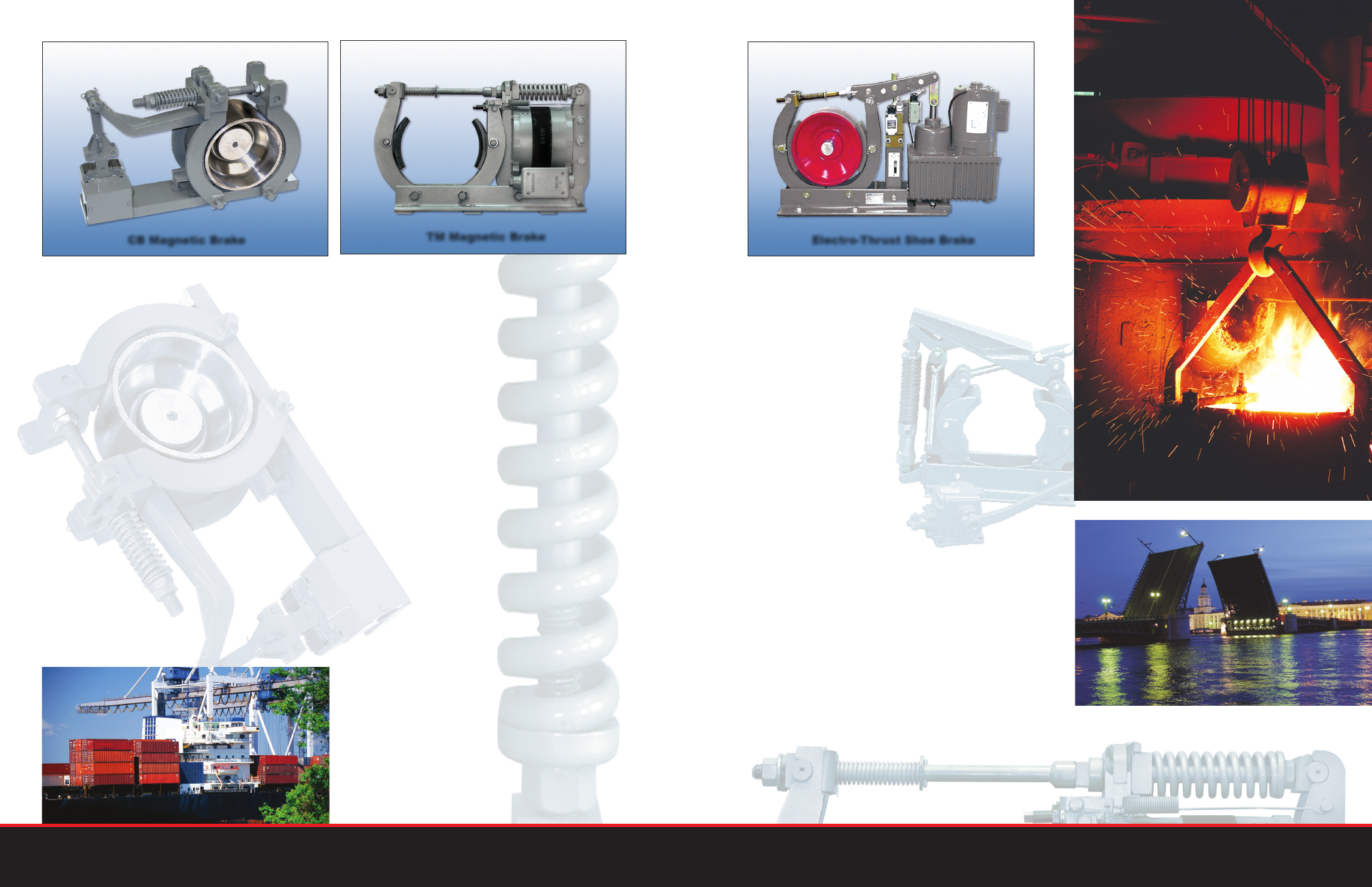

CB Magnetic Brakes

• Spring Applied, Electrically Released

• 4 1/2”-10” Diameter

• 10-160 lbs./ft. Torque

• AC Solenoid Operation

• Single Phase, 60 Hertz Coils

• Asbestos Free Linings

Options

• Enclosures

• Epoxy coatings

CB AC Brakes

• Clean, simple, reliable design with the fewest parts of

any AC brake available today.

• Rugged, long life solenoid - tested in more than two

million operational cycles without electrical failure.

• Simple one-point torque adjustment.

• No separate hand release is required. The brake can be

released by light hand pressure on the solenoid arm.

• Solenoid plunger travel indicator - a mark on the

plunger indicates when the brake should be adjusted for

lining wear.

• Simple two point adjustment for lining wear.

TM Magnetic Brake

CB Magnetic Brake

TM Magnetic Brakes

• Spring Applied, Electrically Released

• AISE Rated

• 4 1/2”-30” Diameter

• 15-9000 lbs./ft. Torque

• DC Operation

• Series or Shunt Coils

• Asbestos Free Linings

Options

• Rectifiers for AC Operation

• Hand Release

• Self-Centering (TMSC Style)

• Hydraulic Over-Ride

• Limit Switches

• Enclosures

• Epoxy coatings

TM DC Brakes

Shunt or Series Wound

• Mechanically independent coils can be removed without

releasing the brake shoes. In an emergency, short-time

operation on a single coil is possible.

• Twin-magnet coils are epoxy-encapsulated for

permanent protection against dust, water, grease, oil,

chemicals, and mechanical impact (TM43 and TM63

have single coils).

• Self-aligning cast iron brake shoes are lined with long

wearing molded linings.

• Shoe travel indicator provides a positive visual check of

lining wear for quick maintenance/inspection.

• Over-the-wheel tie rod is a simple, rugged, easily

accessible linkage, permitting all adjustments from

the top. Standard TM style brakes have two easy

adjustments for lining wear and spring tension. TMSC

style brakes have a single point adjustment for lining

wear and spring tension.

• Utilized tie rod-and-spring assembly facilitates shoe

replacement. The brake can be released manually if

required.

Electro-Thrust Shoe Brake

Electro-Thrust Shoe Brakes

• Spring Applied, Electrically Released

• AISE Rated

• 6”-30” Diameters

• 60-9000 lbs./ft. Torque

• AC or DC Actuators

• Self-Centering

• Multiple Voltage Inputs

• External Torque Springs

• Asbestos Free Linings

• Set Delay Valve

• Adjustable Setting Time

• Stainless Steel Pivot Pins

Options

• Hand Release

• Low Temperature Fluid

• Limit Switches

• Hydraulic Over-Ride

• Enclosures

• Epoxy Paint Coatings

• Self-Adjusting

ET Electro-Thrust Brakes

• Electro-thrust actuator

• Self aligning cast iron shoes

• Over-the-wheel tie rod-and-spring assembly

• Asbestos free bonded linings

• External torque spring

• Floor mounting

• Torque indicator

• Hand release

• Corrosion-resistant fittings

Hydraulic, Magnetic & Electro-Thrust Brake Systems

Hydraulic, Magnetic & Electro-Thrust Brake Systems