AMETEK 5200 Solid State Relay User Manual

Page 4

Copyright 2007 by AMETEK Automation & Process Technologies

1080 N. Crooks Road, Clawson, MI 48017 Toll Free 800-635-0289

Phone 248-435-0700 Fax 248-435-8120 www.ametekapt.com

432

5200.M4R

5/07.Z152

G - One Level Operation

If load relay operates at one level only (starts and stops at one electrode), check

following:

1. Electrode Wires - See Section B-1.

2. Holding Circuit

If the holding circuit (contacts 1-7) is not opening, the load relay will operate from

the lower electrode only. If holding circuit is not closing, the relay will operate from

the upper electrode only. As in Section B-2 for direct operation, if contact 1-7 is

defective, contacts 2-8 can be used as an alternate holding circuit contact.

H - Intermittent Operation

If load relay occasionally short cycles or operates intermittently, check the

following:

1. See Section C-1 and C-2.

2. Check Section J-3 and J-5.

I - Constant Chatter

If load relay chatters continuously, check as in Section F-2. If relay now operates

correctly, check Sections J-3 & J-5, G, and H.

If load relay still chatters with terminals 14 & 15 disconnected, the relay is

defective or there is a defective capacitor in the circuit board.

J - Load Relay Will Not Drop Out

If the relay will not drop out when the liquid touches upper electrode, check the

following:

1. Defective Control - See F-2.

2. Poor Ground Connections

A good dependable ground connection should be made to terminal 15 to complete

the circuit back to terminal 14 as indicated in Section A-3.

3. Broken Wires

A broken or loose wire from the control to upper electrode or ground (common

electrode) will prevent load relay from dropping out. Check as in Section A-4, but

“pull in” should be replaced with “drop out” in the description.

4. Sensitivity Resistor Too Low

If the sensitivity is too low, the load relay will not drop out, or will buzz and chatter.

See A-5, but “pull in” should be replaced by “drop out”.

5. Fouled Electrodes

Accumulated deposits on the electrodes will insulate them, and prevent

the load relay from dropping out. See Section A-6.

6. Electrodes Too Short - See Section A-7.

CONTROL REPAIRS

All B/W controls are tested at the factory prior to shipment to insure proper

operation. They should be handled with care during installation to avoid breaking

electrical connections. If the control does not operate properly after it has been

installed, and service instructions indicate a defect, repair should be attempted

only by an experienced electronic technician as follows:

CHECK TRANSFORMER

With the ac line voltage applied to terminals 10 & 11 or 10 & 12 as shown on

Form 448, the following voltages should be read between the transformer wire

connections on back of the control (±15%):

Black to Orange ..........................115 volts

Black to Blue .............................. 230 volts

Red to White ............................... 3.6 volts

Red to Brown .............................. 7.2 volts

Brown to White ........................... 3.6 volts

Green to Yellow ........................... 30 volts

If these out-put voltages are not present, and in-put voltages check, the

transformer is defective and should be replaced.

TEST CIRCUIT BOARD AND LOAD RELAY

Direct Operation

Test the control as in A-2 with jumper between terminals 13 & 14. If load relay

does not pull in, check on circuit board between two black wires leading from

load relay for a reading of 22 to 26 volts dc. If the voltage reading is low, the

circuit board is defective. If the voltage reading is high (39 to 44 volts dc), the

load relay has an open coil.

Inverse Operation

Test the control as in F-2 with jumper removed. If load relay does not pull

in, check as above for 22 to 26 volts dc. If voltage is low, circuit board is

defective. If voltage is high (39 to 44 volts dc), load relay has an open coil.

Replace the circuit board or the load relay as required. See parts list for

details. If a competent technician is not available, the control should be

returned to factory for repair or replacement.

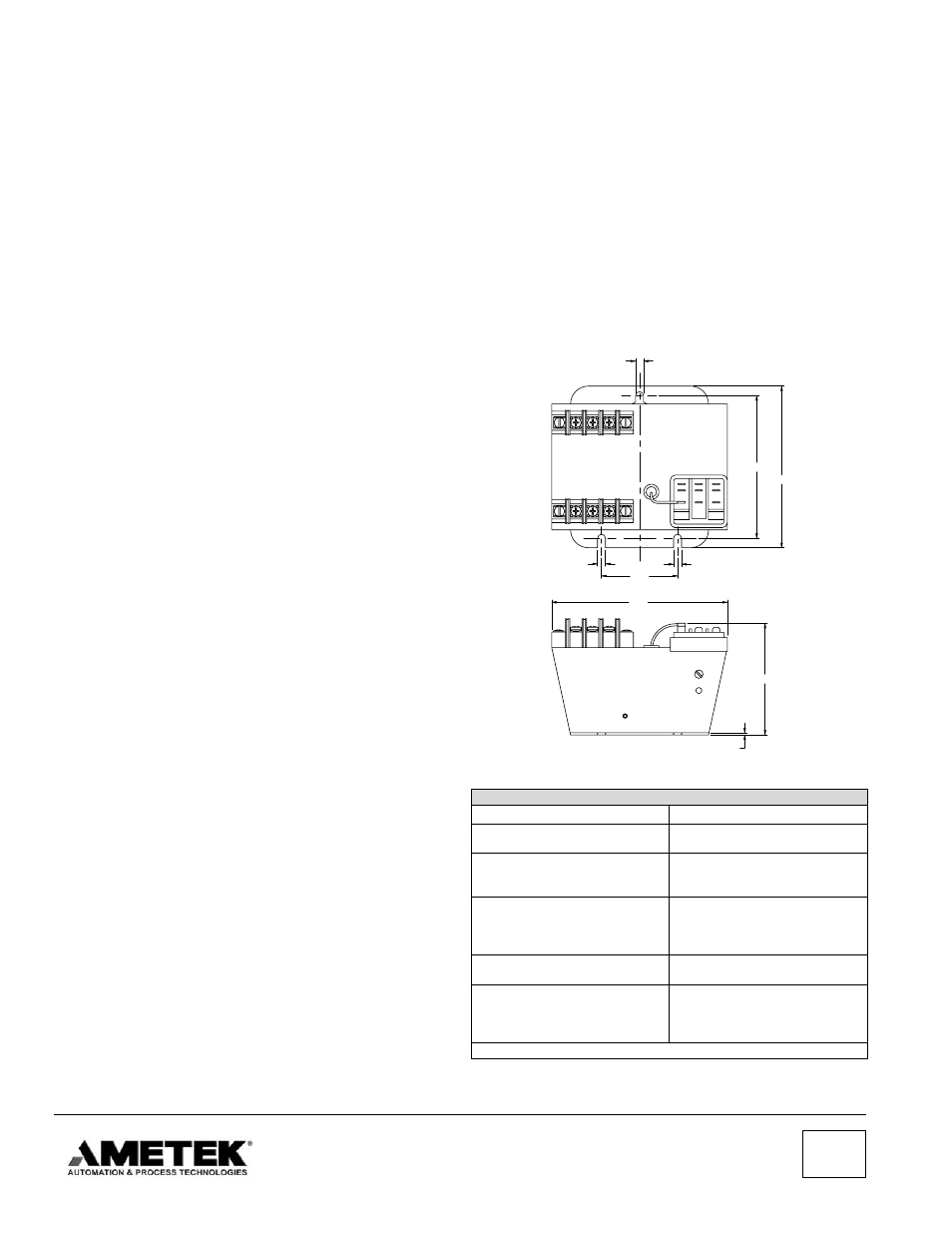

5200 RELAY CHASSIS DIMENSIONS

Replacement Parts for 5200 Solid State Controls

Description

Part Number

Resistor Set - Low

Resistor Set - High

52-110105

52-120105

*Potentiometer Kits for 5200-LV

Range LV1

Range LV2

52-110205

52-110206

*Potentiometer Kits for 5200-HV

Range HV3

Range HV4

Range HV5

52-120205

52-120206

52-120207

Circuit Board - Low

Circuit Board - High

52-110114

52-120114

Transformer

Load Relay

Terminal Block - Line

Terminal Block - Probe

52-110106

04-261900

04-281900

04-281800

*See Sensitivity Range table shown on page 2.