0 troubleshooting, 0 troubleshooting table – ARI Armaturen RI21 EN User Manual

Page 21

Rev. 0040602000 1014

Page 2-21

Operating and installation instructions

Electronic position indicator RI21

8.0 Troubleshooting

In the event of malfunction or faulty operating performance check that the installation and

adjustment work has been carried out and completed in accordance with these Operating

Instructions.

-

ATTENTION !

It is essential that the safety regulations are observed when identifying faults.

If malfunctions cannot be eliminate with the help of the following table

“9.0 troubleshooting table”, the supplier or manufacturer should be consulted.

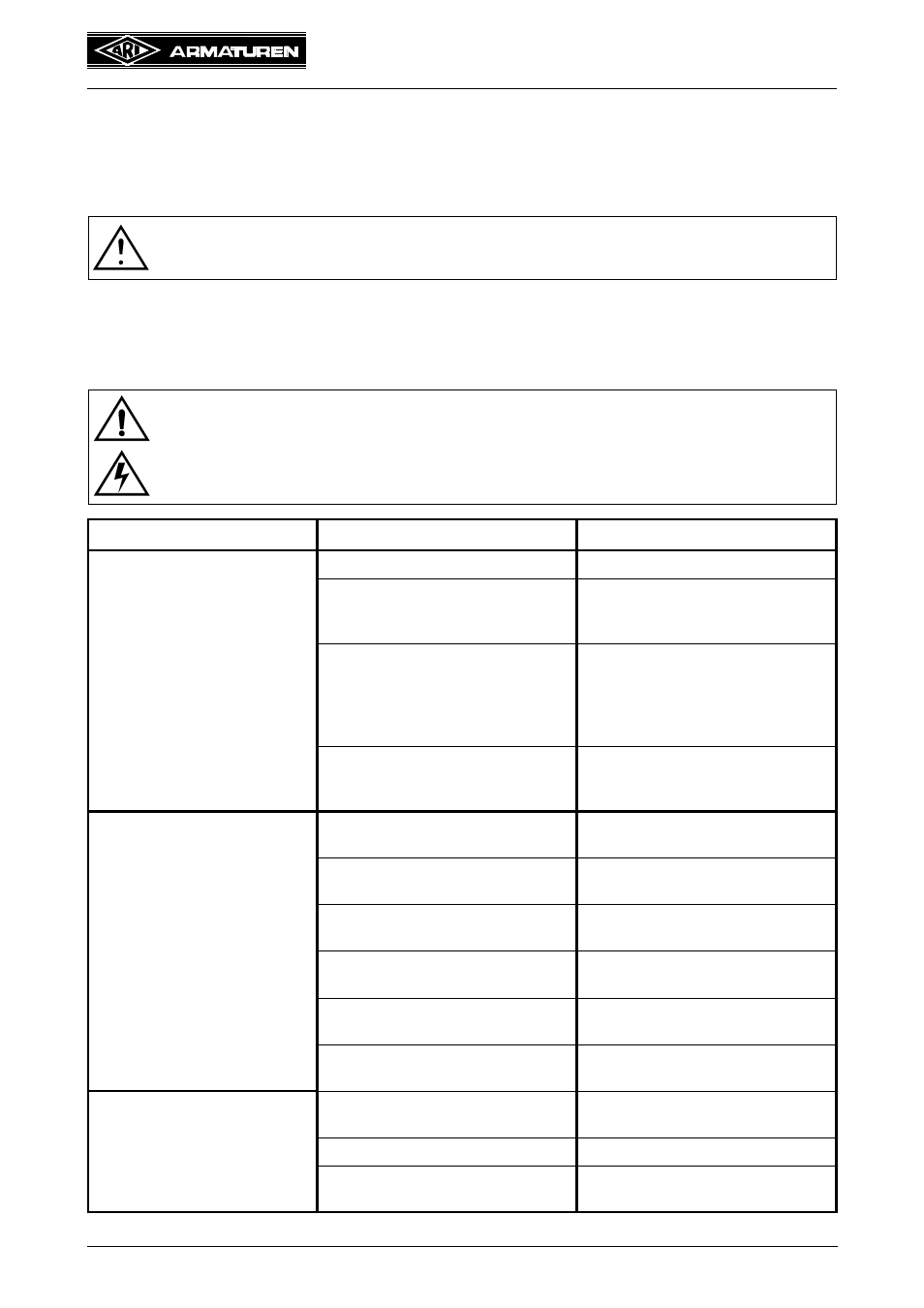

9.0 Troubleshooting table

ATTENTION !

- read point 10.0 and 11.0 prior to dismantling and repair work!

- read point 6.0 before restarting the plant !

Faults

Possible causes

Corrective measures

Yellow LED is not lit

- Mains failure

- Check power supply

- Incorrect operating voltage

- Connect operating voltage in

accordance with type identification

plate

- electronic position indicator burnt

out

- Check whether mains voltage

agrees with the voltage specified

on type identification plate.

Replace electronic position indica-

tor.

- Connection terminal not connected

correctly or cable has no contact in

connection terminal

- Firmly plug in connection terminal

and check connection cable

electronic position indicator can-

not be adjusted

- Potentiometer not connected cor-

rectly

- Check connections

- Potentiometer has incorrect value

rating

- Replace potentiometer by

1000

potentiometer

- Potentiometer connected to incor-

rect terminal

- Correct connection in accordance

with circuit diagram

- No signal present at output

- Perform settings as under 6.0

through 6.5

- Actuating signal connected to incor-

rect terminal

- Correct connection in accordance

with circuit diagram

- Adjusting screws N (zero point) and

S (slope) are out of range

- Carry out settings as described

Output positioning signal in-

capable of being set over the

entire setting distance

- Spur gear transmission ratio at

potentiometer incorrect

- Adapt spur gear transmission ratio

to control range

- Wrong potentiometer

- Use 1000 ohm potentiometer

- Adjusting screws N (zero point) and

S (slope) are out of range

- Carry out settings as described