3 bellows seal design – ARI Armaturen STEVI 471 EN User Manual

Page 10

Page 10

Rev. 0040305000 0410

Operating and installation instructions

Straight through control valves - STEVI

®

470 / 471

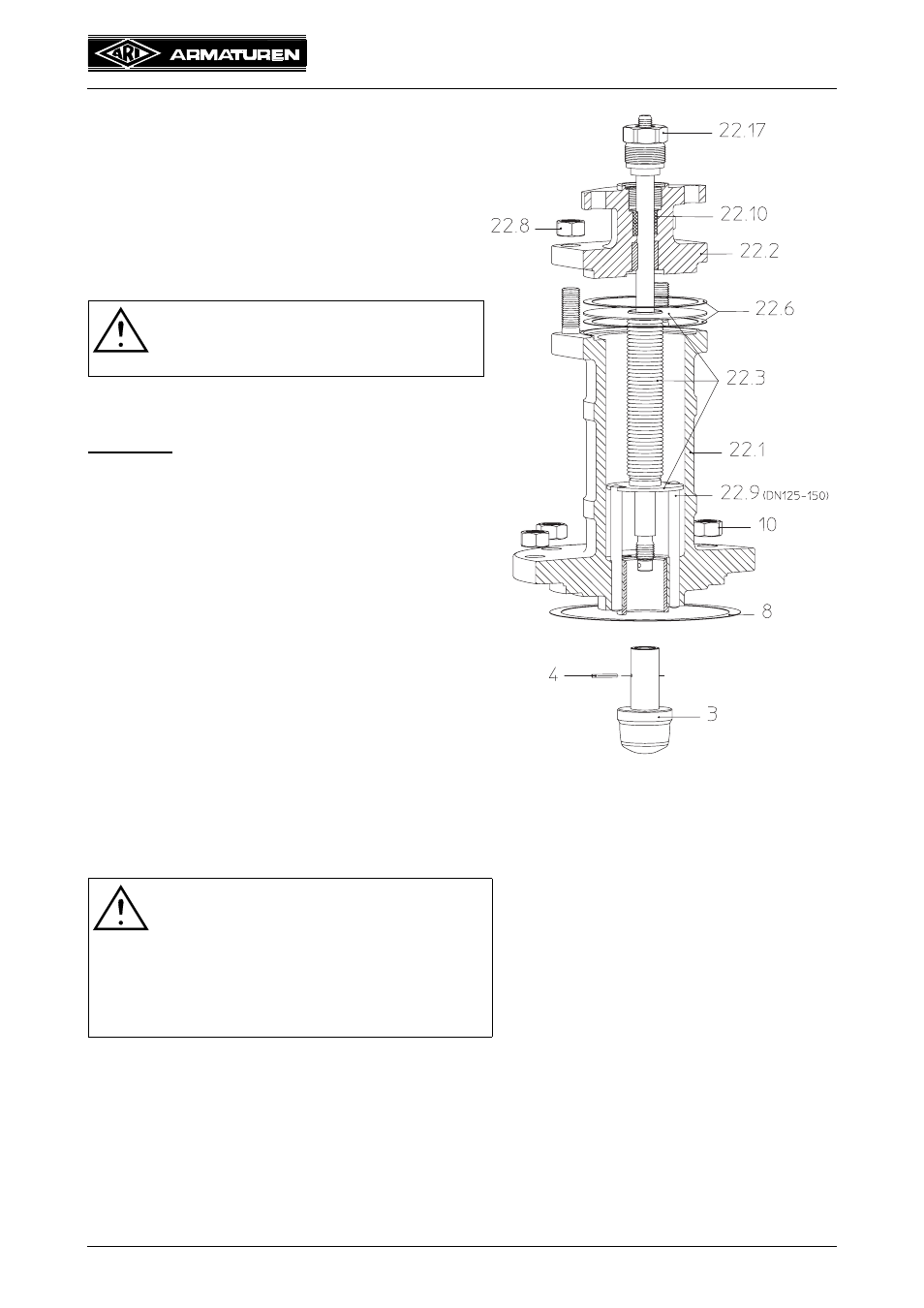

7.1.3 Bellows seal design

If the stem leaks the bellows seal (pos. 22.2) is

defective. The leak can initially be stopped by

tightening the screw joint (pos. 22.17)

respectively the sleeve nut (pos. 22.16).

Stem and bellows (pos. 20.3) can only be

replaced together.

Replacement of bellows seal:

- Remove actuator.

(Refer to operating instructions for actuator!)

DN15-150

- Loose nuts (pos. 10).

- Detach bellows assembly (pos. 22).

- Slacken screw joint (pos. 22.17) by about one

turn.

- Press stem-/bellows unit (pos. 22.3) down.

- Drive pin (pos. 4) out with a drift.

- Unscrew plug (pos. 3).

- Loose nuts (pos. 22.8).

- Detach mounting bonnet (pos. 22.2).

- Extract stem-/bellows unit (pos. 22.3) from

the bellows housing (pos. 22.1).

- Bolt new parts together and drill them.

- Replace 2 gaskets (pos. 22.6) and 1 gasket

(pos. 8).

- Assemble in reverse order.

- Secure with nuts (pos. 10 and 22.8) and tighten them crosswise.

(For tightening torques refer to item 7.3.1)

- Tighten screw joint (pos. 22.17) resp. sleeve nut (pos. 22.16) gradually up to tightness of

the stuffing box packing (pos. 22.10).

ATTENTION !

Refer to item 10.0 and 11.0 before

dismantling the valve.

ATTENTION at DN125-150!

- Ensure that the torsion lock is

correctly positioned when inserting

new stem/bellows unit. Introduce the

grooved pin (pos. 20.9) into the

torsion lock groove.

Make sure it runs smoothly!

Fig. 14: Series 471 DN 15-150