ARI Armaturen SAFE-TCP/TCS950 EN User Manual

Page 13

Rev. 0040401000 2913

Page 2-13

Operating and installation instructions

SAFE, SAFE-P, SAFE-TC, SAFE-TCP/TCS

- when carrying out any adjustment work hold the spindle (pos. 14) firm to prevent it

twisting.

- Change seals.

- Fit bonnet (pos. 11/42) and reset the set pressure; make sure spring setting range is

appropriate.

- Secure spring setting by means of lock nut (pos. 21).

- Assemble lifting device.

- If necessary, replace both spring plates (pos. 26) and use longer studs (pos. 3) when

fitting a spring for a higher set pressure.

- Further information obtainable from the manufacturer.

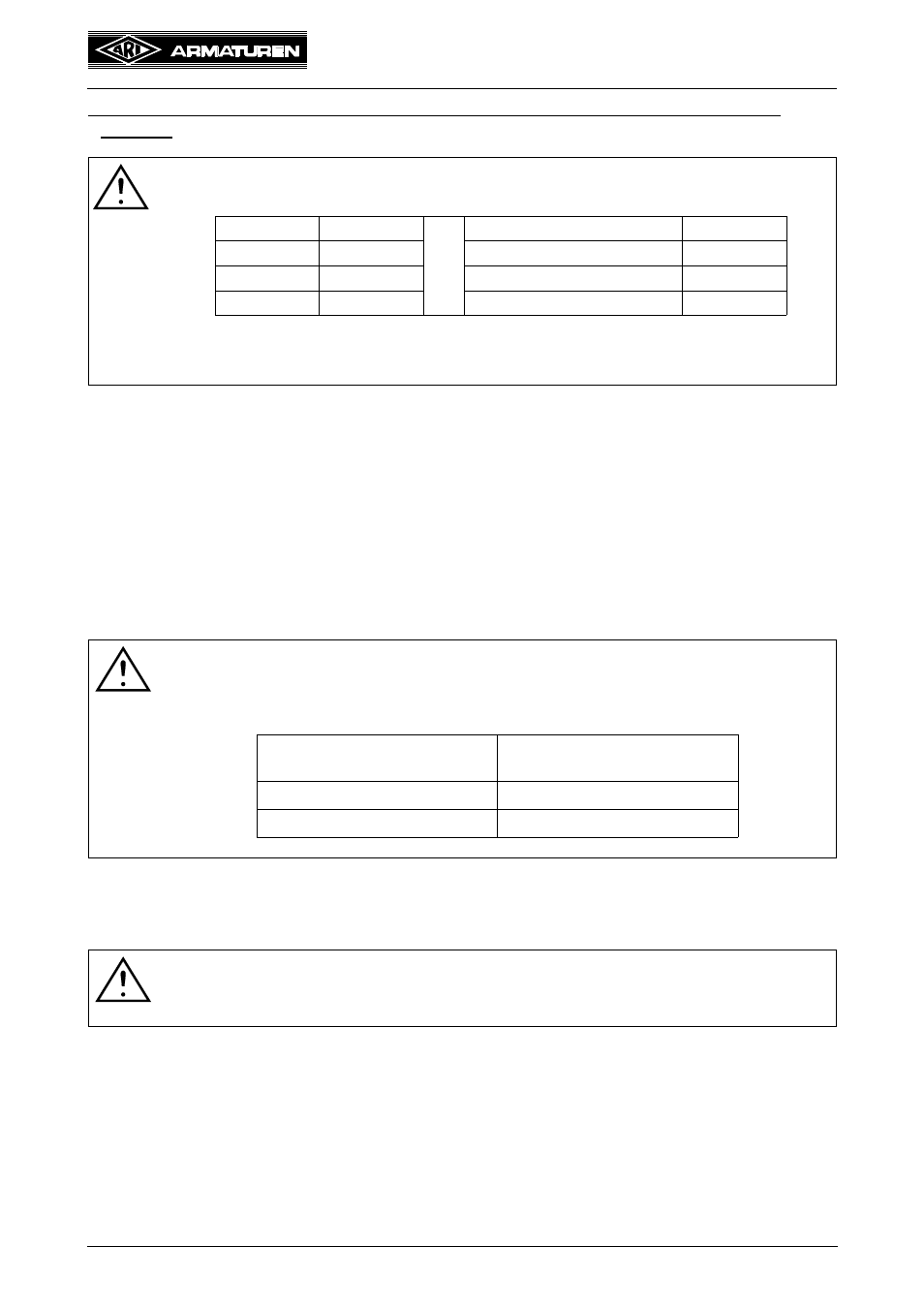

ATTENTION !

- Torques must be observed:

- Check spring marking in accordance with manufacturer’s data.

- Note spring setting range.

Only for series 900: DN20-100 (except safety valves with ASME approval)

ATTENTION !

When changing the set pressure and fitting a new spring, note that safety valves

with set pressures between 0.2 and 1.5 bar have a greater lift.

Therefore:

Only for series 950:

ATTENTION !

Safety valves for horizontal application, must also to be set in a

horizontal position (

4.9 bar).

M10

16-25 Nm

screw joint BR940

100 Nm

M12

30-40 Nm

screwed seat BR940

180 Nm

M16

70-90 Nm

bonnet BR950/960

60 Nm

M20

150-175 Nm

Set pressure in the range

Spring change only in

the range

0.2 to 1.5 bar

0.2 to 1.5 bar

> 1.5 bar

> 1.5 bar