0 troubleshooting table, 0 troubleshooting table -10, Operating and installation instructions checko – ARI Armaturen CHECKO-D PN40 EN User Manual

Page 10: V pn6-160 / checko, D pn40

Page 2-10

Rev. 0040106000 1613

Operating and installation instructions

CHECKO

®

-V PN6-160

/ CHECKO

®

-D PN40

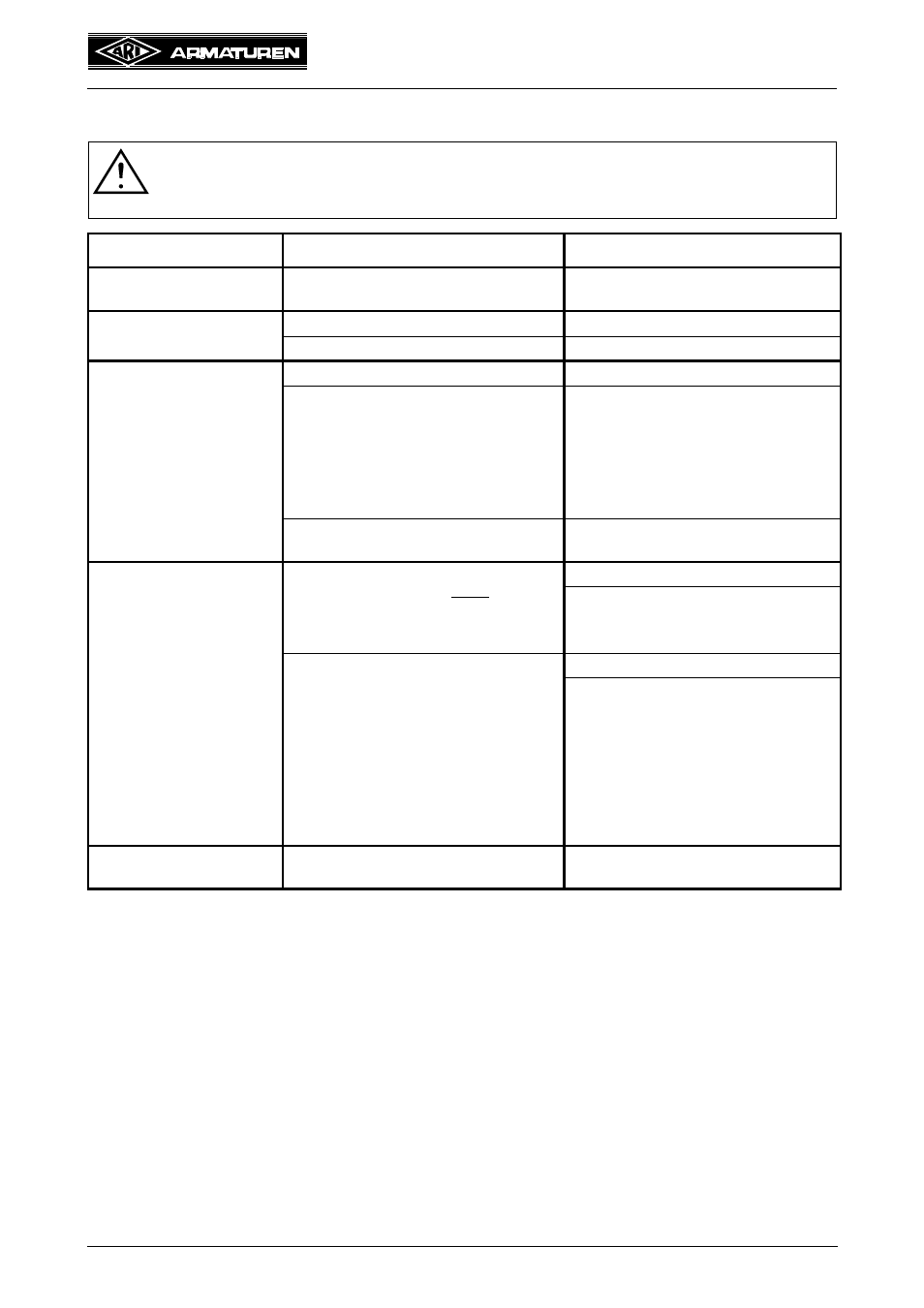

9.0 Troubleshooting table

ATTENTION !

- read point 10.0 and 11.0 prior to dismantling and repair work!

- read point 6.0 before restarting the plant !

Fault

Possible cause

Corrective measures

No flow

Flange covers not removed.

(pos. 8; Fig. 1-2)

Remove flange covers.

(pos. 8; Fig. 1-2)

Little flow

Dirt sieve clogged.

Clean / replace sieve.

Piping system clogged.

Check piping system.

Leakage across valve seat. Wrong Installation

Correct the Installation (see point 5.1).

CHECKO

®

-V:

Seat (pos. 1.2) / plug (pos. 3) damaged

by foreign particles. (Fig. 1-6).

CHECKO

®

-D:

Body (pos.1) / valve plate (pos. 8) dam-

aged by foreign particles (Fig. 7)

Replaced valve, consult supplier/manu-

facturer.

Medium contaminated

(suspended solids).

Clean valve.

Install dirt screen upstream of valve.

Rattling / banging

of the plug resp. of the

valve plate

Nominal diameter of the valve in compli-

ance to the flow rate is to big

Choose smaller nominal diameter

CHECKO

®

-V:

Use a plug damper execution: see

medium

- high flow turbulences;

- the check valve is mounted directly by

a centrifuged pump;

- behind pressure reduction stations;

- behind pipe elbows;

- in compact plants;

- expansion joints are missing;

- the pump is not mounted on a damper;

- there is no flow stabilizing pipe length;

- there is no start-up bypass line

Alter the system

CHECKO

®

-V:

Use a plug damper execution: see

medium

Flange broken between

valve and piping.

Bolts tightened unevenly.

Mating flanges not properly aligned.

Re-align piping and fit new valve!