0 troubleshooting, 0 troubleshooting table, 0 troubleshooting 9.0 troubleshooting table – ARI Armaturen EURO-WEDI EN User Manual

Page 8: Operating and installation instructions euro-wedi

Page 8

Rev. 0040104000 0410

Operating and installation instructions

EURO-WEDI

®

8.0 Troubleshooting

In the event of malfunction or faulty operating performance check that the installation and

adjustment work has been carried out and completed in accordance with these Operating

Instructions.

If malfunctions cannot be eliminate with the help of the following table

“9.0 troubleshooting table”, the supplier or manufacturer should be consulted.

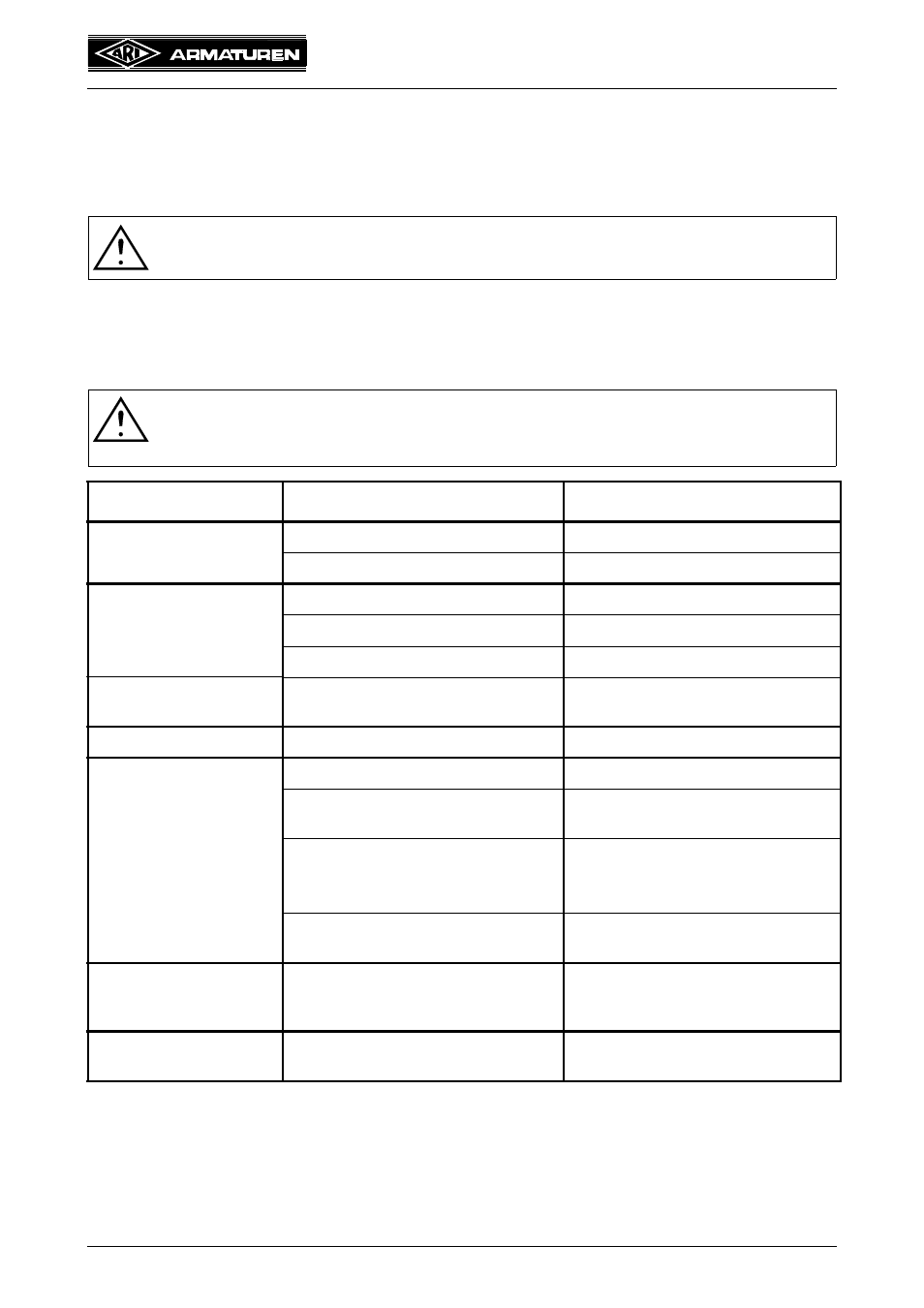

9.0 Troubleshooting table

-

ATTENTION !

It is essential that the safety regulations are observed when identifying faults.

ATTENTION !

- read point 10.0 and 11.0 prior to dismantling and repair work!

- read point 6.0 before restarting the plant !

Fault

Possible cause

Corrective measures

No flow

Valve closed.

Open valve.

Flange covers not removed.

Remove flange covers.

Little flow

Valve not sufficiently open.

Open valve.

Dirt sieve clogged.

Clean / replace sieve.

Piping system clogged.

Check piping system.

Valve difficult to move or

cannot be opened

Wrong direction of rotation

Turn in correct direction (anticlockwise

to open valve).

Valve spindle leaking

EDD-special spindle seal

Replace valve or bonnet.

Leakage across valve seat. Valve not properly closed.

Pull hand wheel tight without tools.

Seat (1) / plug (3) damaged by foreign

particles. (fig. 1-4).

Replaced valve, consult supplier/manu-

facturer.

Pressure difference too high.

Check system pressure and pressure

drop (max.

Δp = 16 bar).

Reduce system pressure.

Medium contaminated

(suspended solids).

Clean valve.

Install dirt screen upstream of valve.

Valve with stroke limiter

and locking device cannot

be opened.

Stroke limiter on spindle stop has been

tightened.

Locking device has been tightened.

Turn stroke limiter upwards.

Slacken the locking device.

Flange broken between

valve and piping.

Bolts tightened unevenly.

Mating flanges not properly aligned.

Re-align piping and fit new valve!