Maintenance, Check the igniter assembly and main burners, Igniter assembly – State SBN85 390NE A User Manual

Page 28: Main burner, Venting system, Remote storage tank temperature control, Temperature-pressure relief valve test

28

CheCk the igniter assemBly and main Burners

At least once a year, check the igniter assembly, Figure 25, and

the main burner, Figure 26, for proper operation. refer to the

following igniter assembly and main burner sections.

igniter assemBly

For access to igniter assembly, unfasten two screws to burner

cover and remove. locate the burner with the igniter assembly

and remove screw holding burner to manifold. Slide burner out

to access igniter assembly.

Servicing of the igniter assembly includes keeping the igniter free

of lint, scale or any other foreign debris.

figure 25. igniter

main Burner

The main burner, Figure 26, should display the following

characteristics:

• Cause rapid ignition and carry across entire burner.

• Give reasonably quiet operation during ignition, burning, and

extinction.

• Cause no excessive lifting of flame from burner ports.

figure 26.

If the preceding burner characteristics are not evident, check for

accumulation of lint, scale or other foreign debris that restricts or

blocks the air openings to the burner or heater.

NOTe:

1. remove main burners from unit.

2. Check that burner venturi and ports are free of foreign debris.

3. Clean burners with bristle brush and/or vacuum cleaner - DO

NOT distort burner ports or igniter location.

4. reinstall burners in unit. Make sure front and rear of burners

are installed correctly in burner support brackets.

Also check for good flow of combustion and ventilating air to the

unit. Maintain a clear area around the heater at all times.

Venting system

examine the venting system every six months for obstructions

and/or deterioration of the vent piping.

remove all soot or other obstructions from chimney which will

retard free draft.

remote storage tank temperature Control

The water temperature in the remote storage tank (if used) is

controlled by the storage tank temperature control. The sensing

element is mounted in the hot water storage tank, see Water

Piping Diagram section.

A change in water temperature in the storage tank lower than

the tank temperature control setting will cause the sensor to

activate the circulating pump. The pump then circulates the water

through the heater where the thermostat senses the drop in water

temperature and activates main burner operation of the appliance.

If the storage tank temperature control is out of calibration, replace

with new control.

ShOUlD OVerheATING OCCUr Or The GAS SUPPly FAIl

TO ShUT OFF, TUrN OFF The MANUAl GAS CONTrOl VAlVe

TO The APPlIANCe.

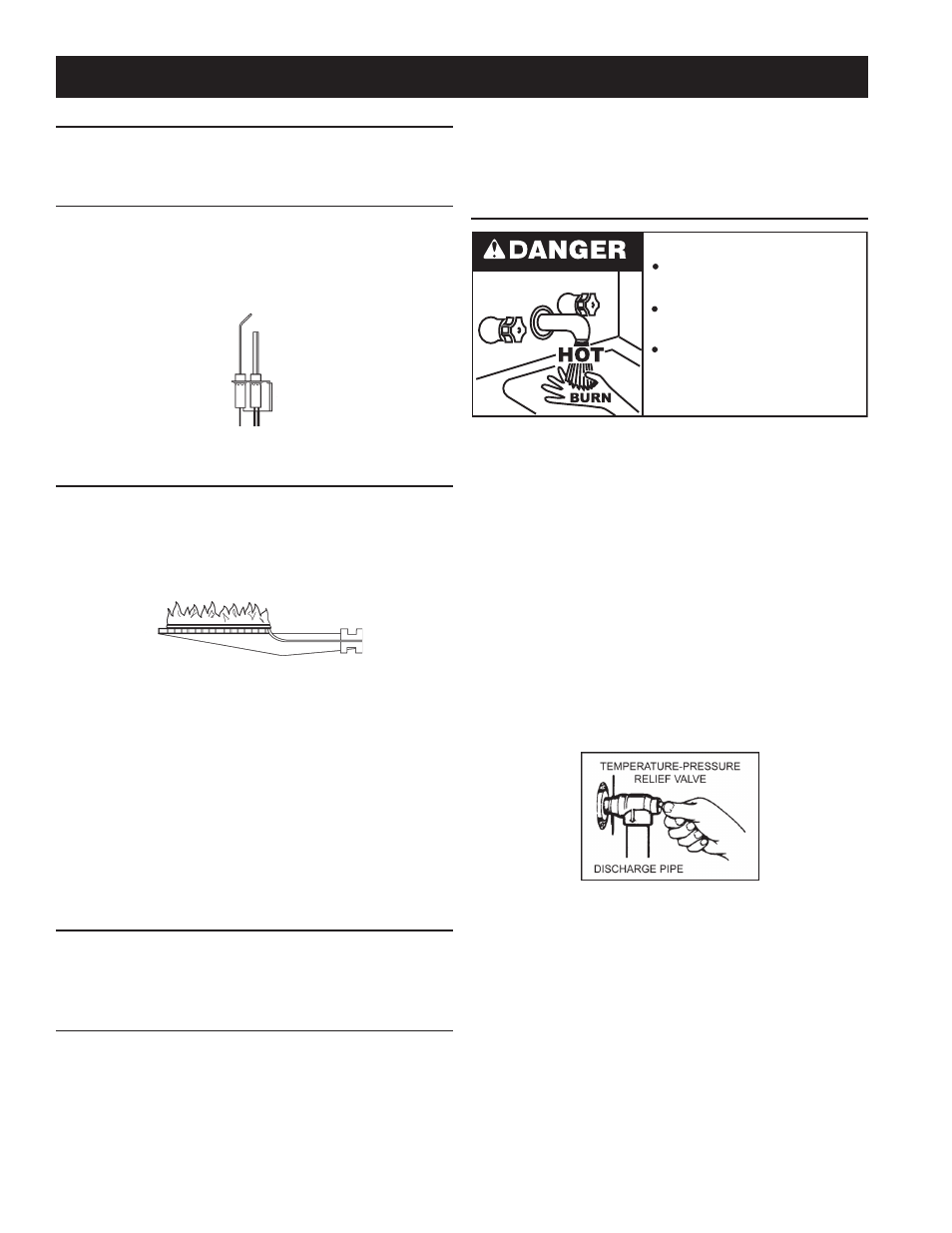

temperature-pressure relief ValVe test

Burn hazard.

Hot water discharge.

Keep clear of Temperature-

Pressure Relief Valve

discharge outlet.

It is recommended that the Temperature-Pressure relief Valve should

be checked to ensure that it is in operating condition every 6 months.

When checking the Temperature-Pressure relief Valve operation,

make sure that (1) no one is in front of or around the outlet of the

Temperature-Pressure relief Valve discharge line, and (2) that the

water discharge will not cause any property damage, as the water

may be extremely hot. Use care when operating valve as the valve

may be hot.

To check the relief valve, lift the lever at the end of the valve several

times, see Figure 27. The valve should seat properly and operate

freely.

If after manually operating the valve, it fails to completely reset and

continues to release water, immediately close the cold water inlet

to the water heater and drain the water heater, see Draining And

Flushing on page 29. replace the Temperature-Pressure relief

Valve with a properly rated/sized new one, see Temperature-Pressure

relief Valve on pages 13-14 for instructions on replacement.

figure 27.

If the Temperature-Pressure relief Valve on the water heater weeps

or discharges periodically, this may be due to thermal expansion.

NOTe: excessive water pressure is the most common cause of

Temperature-Pressure relief Valve leakage. excessive water

system pressure is most often caused by "thermal expansion"

in a "closed system." See Closed Water Systems and Thermal

expansion on page 13. The Temperature-Pressure relief Valve is

not intended for the constant relief of thermal expansion.

Temperature-Pressure relief Valve leakage due to pressure build

up in a closed system that does not have a thermal expansion

tank installed is not covered under the limited warranty. Thermal

expansion tanks must be installed on all closed water systems.

DO NOT PlUG The TeMPerATUre-PreSSUre relIeF

VAlVe OPeNING. ThIS CAN CAUSe PrOPerTy DAMAGe,

SerIOUS INJUry Or DeATh.

maintenanCe