Danger – State GS6 75 URRBS User Manual

Page 8

8

fuel burning equipment. This practice is prohibited by many local

building codes as is the practice of venting gas fi red equipment to

the duct work of ventilation systems.

•

Where a separate vent connection is not available and the vent

pipe from the heater must be connected to a common vent with an

oil burning furnace, the vent pipe should enter the smaller common

vent or chimney at a point above the large vent pipe.

FIGURE 3.

VENT CONNECTION

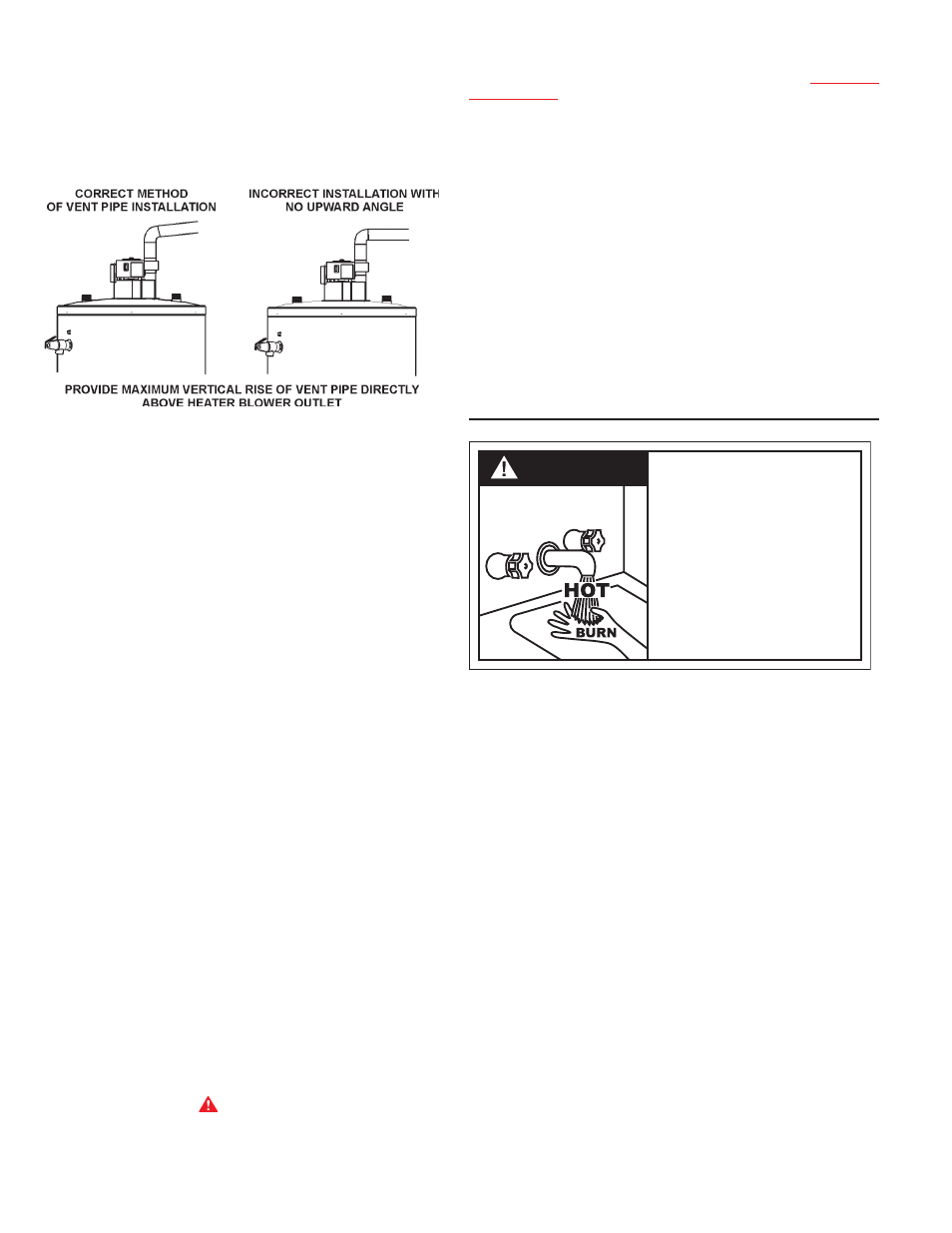

Vent connections must be made to an adequate stack or chimney. Size

and install proper size vent pipe. Do not reduce pipe size to less than

that of the blower outlet.

Horizontal runs of vent pipe must have a minimum upward slope

toward the chimney of 1/4 inch per foot (2cm per meter). Dampers or

other obstructions must not be installed in between the heater and the

blower. Be sure that the vent pipe does not extend beyond the inside

wall of the chimney.

Where a continuous or intermittent back draft is found to exist, the

cause must be determined and corrected. A special vent cap may be

required. If the back draft cannot be corrected by the normal methods or

if a suitable draft cannot be obtained, a blower type fl ue gas exhauster

must be employed to assure proper venting and correct combustion.

THERMOMETERS (Not Supplied)

Thermometers should be obtained and fi eld installed as shown in Figure 3.

Thermometers are installed in the system as a means of detecting the

temperature of the outlet water supply.

COMBINATION WATER (POTABLE) HEATING

AND SPACE HEATING

1. All piping components connected to this unit for space heating

applications shall be suitable for use with potable water.

2. These water heaters connot be used in space heating applications

only.

3. Toxic chemicals, such as those used for boiler treatment, shall

NEVER be introduced into this system.

4. This unit may NEVER be connected to any existing heating system

or component(s) previously used with a non-potable water heating

appliance.

5. When the system requires water for space heating at temperatures

higher than required for domestic water purposes, a tempering valve

must be installed. Please refer to installation diagram on page 6 of

this manual for suggested piping arrangements.

CAUTION

A closed system will exist if a check valve (without bypass), pressure

reducing valve (without bypass), or a water meter (without bypass) is

installed in the cold water line between the water heater and street

main (or well).

Excessive pressure may develop in such closed systems, causing

premature tank failure or intermittent relief valve operation. This is not a

warranty failure. An expansion tank or a similar device may be required

in the inlet supply line between the appliance and the meter or valve to

compensate for the thermal expansion of the water.

As water is heated, it expands (thermal expansion). In a closed system, the

volume of water will increase. As the volume of water increases, there will

be a corresponding increase in water pressure due to thermal expansion.

Thermal expansion can cause premature tank failure (leakage). This type

of failure is not covered under the limited warranty. Thermal expansion

can also cause intermittent temperature-pressure relief valve operation:

water discharged from the valve due to excessive pressure build up. The

temperature-pressure relief valve is not intended for the constant relief

of thermal expansion. This condition is not covered under the limited

warranty.

A properly-sized thermal expansion tank should be installed on all closed

systems to control the harmful effects of thermal expansion. Contact a

plumbing service agency or your retail supplier reguarding the installation

of a thermal expansion tank.

MIXING VALVES

DANGER

Water temperature over 125°F (52°C)

can cause severe burns instantly

resulting in severe injury or death.

Children, the elderly and the physically

or mentally disabled are at highest risk

for scald injury.

Feel water before bathing or showering.

Temperature limiting devices such as

mixing valves must be installed when

required by codes and to ensure safe

temperatures at fixtures.

Water heated to a temperature which will satisfy clothes washing, dish

washing, and other sanitizing needs can scald and cause permanent

injury upon contact. Short repeated heating cycles caused by small hot

water uses can cause temperatures at the point of use to exceed the

water heater’s temperature setting by up to 20°F (11°C).

Some people are more likely to be permanently injured by hot water than

others. These include the elderly, children, the infi rm and the physically/

mentally disabled. Table 1 shows the approximate time-to-burn

relationship for normal adult skin. If anyone using hot water provided by

the water heater being installed fi ts into one of these groups or if there

is a local code or state law requiring a certain water temperature at the

point of use, then special precautions must be taken.

In addition to using lowest possible temperature setting that satisfi es demand of

application a Mixing Valve should be installed at water heater (see Figure 3)

or at hot water taps to further reduce system water temperature.

Mixing valves are available at plumbing supply stores. Consult a Qualifi ed

Installer or Service Agency. Follow mixing valve manufacturer’s instructions

for installation of the valves.