Service information – State GS6 75 URRBS User Manual

Page 14

14

Type of Gas

BTU Per Cu. Ft.

Time Required To Consume 1 Cu.

Ft. of Gas

Natural

1050

50.3 Seconds

CHECKING VENTING

The following steps shall be followed with each appliance connected

to the venting system placed in operation, while any other appliances

connected to the venting system are not in operation.

1. Seal any unused openings in the venting system.

2. Inspect the venting system for proper size and horizontal pitch, as

required in the National Fuel Gas Code, ANSI Z223.1/NFPA 54

Installation codes and these instructions. Determine that there is

no blockage or restriction, leakage, corrosion and other defi ciencies

which could cause an unsafe condition.

3. So far as is practical, close all building doors and windows and all

doors between the space in which the water heater(s) connected

to the venting system are located and other spaces of the building.

Turn on all appliances not connected to the venting system. Turn

on all exhaust fans, such as range hoods and bathroom exhausts,

so they shall operate at maximum speed. Close fi replace dampers.

4. Follow the lighting instruction. Place the water heater being

inspected in operation. Adjust thermostat so appliance shall operate

continuously.

5. Test for vent system leakage after 5 minutes of main burner

operation.

6. After it has been determined that each appliance connected to the

venting system properly vents when tested as outlined above, return

doors, windows, exhaust fans, fi replace dampers and any other gas

burning appliance to their previous conditions of use.

7. If improper venting is observed during any of the above tests, the

venting system must be corrected.

WARNING

FAILURE TO CORRECT BACK DRAFTS MAY CAUSE AIR

CONTAMINATION AND UNSAFE CONDITIONS.

HIGH TEMPERATURE LIMIT SWITCH (ECO)

The water heater is equipped with a manual reset type high limit (Energy

Cutoff) sensor. The high limit switch interrupts the main burner gas fl ow

should the water temperature reach 195°F (90°C). The high limit switch

must be manually reset by turning the power to the water heater off for

5 seconds then back on and cannot be reset until the water temperature

drops below 120°F (49°C). It is important that a serviceman be called

to determine the reason for limit operation and thus avoid repeated

thermostat resetting.

WARNING

THE ON/OFF SWITCH MUST HAVE BEEN IN THE OFF POSITION FOR

AT LEAST 5 MINUTES. This waiting period is an important safety step.

Its purpose is to permit gas that may have accumulated in the combustion

chamber to clear. IF YOU DETECT GAS ODOR AT THE END OF THIS

PERIOD DO NOT PROCEED WITH LIGHTING. RECOGNIZE THAT

GAS ODOR, EVEN IF IT SEEMS WEAK, MAY INDICATE PRESENCE

OF ACCUMULATED GAS SOMEPLACE IN THE AREA WITH RISK

OF FIRE OR EXPLOSION. SEE THE FRONT PAGE FOR STEPS TO

BE TAKEN.

SHOULD OVERHEATING OCCUR OR THE GAS SUPPLY FAIL TO

SHUT OFF, TURN OFF THE MANUAL GAS CONTROL VALVE TO

THE APPLIANCE.

SERVICE INFORMATION

The installer may be able to observe and correct certain problems

which may arise when the unit is put into operation. HOWEVER, it is

recommended that only qualifi ed servicemen, using appropriate test

equipment, be allowed to service the heater.

FOR YOUR SAFETY AND SATISFACTORY OPERATION, IT IS

RECOMMENDED THAT THIS HEATER BE CHECKED ONCE A YEAR

BY A COMPETENT SERVICE PERSON.

USERS OF THIS APPLIANCE SHOULD BE AWARE THAT GAS

COMPONENTS WEAR OUT OVER A PERIOD OF TIME. THE GAS

CARRYING COMPONENTS OF THIS APPLIANCE SHOULD BE

INSPECTED FOR PROPER OPERATION PERIODICALLY BY A

QUALIFIED SERVICE TECHNICIAN.

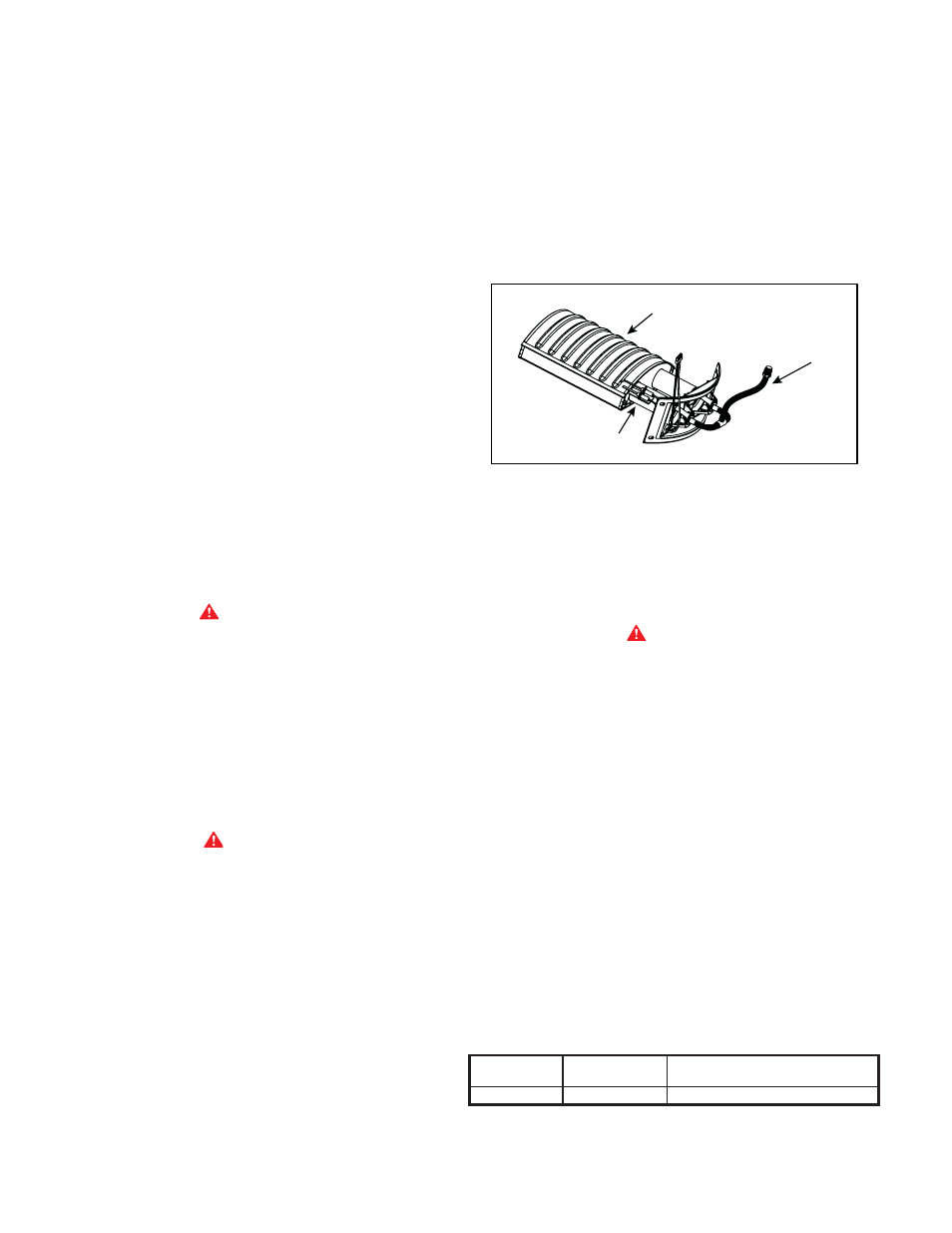

MAIN BURNER AND IGNITER

Check main burner (figure 7) at least every 6 months for proper

fl ame characteristics. The main burner should display the following

characteristics:

BURNER HEAD

ASSEMBLY

BURNER TUBE

ASSEMBLY

H.S.I.

ASSEMBLY

FIGURE 8. MAIN BURNER AND IGNITER ASSEMBLY

1. Provide complete combustion of gas.

2. Cause rapid ignition and carryover of fl ame across entire burner.

3. Give reasonably quiet operation during ignition, burning and extinction.

4. Cause no excessive lifting of fl ames from burner ports.

If preceding burner characteristics are not evident, check for accumulation

of lint or other foreign material that restricts or blocks the air openings

to the heater or burner.

WARNING

SOOT BUILD-UP INDICATES A PROBLEM THAT REQUIRES

CORRECTION BEFORE FURTHER USE. CONSULT WITH A

QUALIFIED SERVICE TECHNICIAN.

Should the main burner or burner air openings require cleaning, remove

the burner and clean with a soft brush. Clean main burner orifi ce with

a suitable soft material.

CHECK FOR GOOD FLOW OF COMBUSTION AND VENTILATING

AIR TO THE UNIT. MAINTAIN A CLEAR OPEN AREA AROUND THE

HEATER AT ALL TIMES. DO NOT STORE COMBUSTIBLES OR

FLAMMABLE LIQUIDS NEAR OR AROUND AN APPLIANCE.

CHECKING GAS INPUT

For appliance installation locations with elevation above 2000 ft.(610m)

refer to HIGH ALTITUDE INSTALLATIONS section of this manual for

input reduction procedure.

With this heater in operation, determine whether it is receiving the full

rated input of gas. This may be done by timing the gas meter and

measuring gas pressure with a gauge or manometer. When the heater is

operating at full capacity (full gas input) it should consume approximately

1 cubic foot of gas in the time shown in table 6.

TABLE

7

INPUT CHECK TIME REQUIRED TO CONSUME 1 CU. FT. OF GAS