Warning – State GS6 40 YBFS User Manual

Page 27

27

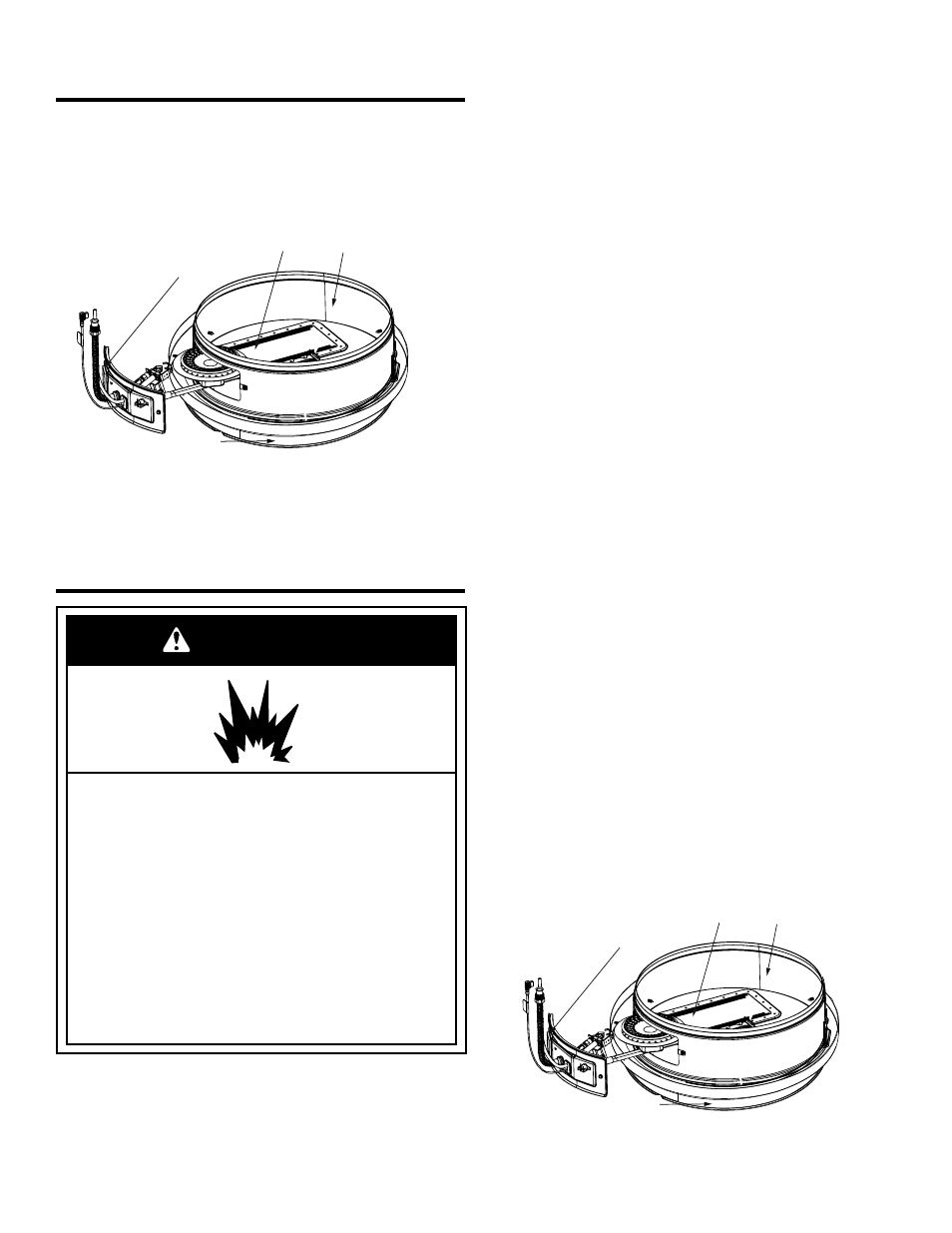

Cleaning the Combustion Chamber and

Flame-arrestor

1. Follow procedure outlined in “Removing the Manifold/

Burner Assembly”.

2. Use a vacuum cleaner/shop vac to remove all loose

debris in the combustion chamber (Figure 32). Use

compressed air to clear any dust or debris that may

have accumulated in the flame-arrestor.

DOOR GASKET

FLAME ARRESTOR COMBUSTION CHAMBER

BASE-RING

FILTER

FIGURE 32.

3. Reassemble following the procedure under “Replacing

the Manifold/Burner Assembly”.

Replacing the Manifold/Burner Assembly

WARNING

Explosion Hazard

• Tighten both manifold door screws securely.

• Remove any fiberglass between gasket and

combustion chamber.

• Replace viewport if glass is missing or damaged.

• Replace two piece wire connector if missing or

removed.

• Replace door gasket if damaged.

• Failure to follow these instructions can result in

death, explosion, or fire.

1. Check the door gasket for damage or imbedded debris

prior to installation.

2. Inspect the view port for damage and replace as

required.

3. Insert the manifold/burner assembly into the burner

compartment, making sure that the tip of the manifold

tube engages in the slot of the bracket inside the com-

bustion chamber (Figures 33 & 34).

4. Inspect the door gasket and make sure there is no

fiberglass insulation between the gasket and the

combustion chamber.

5. Replace the two screws, which secure the manifold/

burner assembly door to the combustion chamber and

tighten securely. Once the manifold/burner assembly

door is tightened, visually inspect the door gasket

between the manifold/burner assembly door and the

combustion chamber for spaces or gaps that would

prevent a seal. IMPORTANT: Do not operate the water

heater if the door gasket does not create a seal be-

tween the manifold door and the combustion chamber.

6. During the following procedure, do not cross-thread

or apply any thread sealant to any of the fittings listed

below. First, reconnect the manifold tubing to the gas

control valve/thermostat. NOTE: L.P. gas systems use

reverse (left-hand) threads on the manifold tube.

NOTE: If a ferrule nut needs to be installed for the pilot

tube, locate the one provided with your parts kit. Install

it in the gas control valve/thermostat at the pilot loca-

tion, hand tight only.

Next, insert the pilot tube into the ferrule nut until it bot-

toms out. NOTE: Hold the tube in this position. Tighten

the ferrule nut with a wrench until the crimp connection

seals to the pilot tube. Continue to tighten until the nut

is tight in the gas control valve/thermostat. When you

are finished, connect the two wire leads that go to the

thermal switch.

7. Reconnect the igniter wire.

8. Turn gas supply on and refer to the Lighting Instruc-

tions.

9. With the burner lit, check the gas control valve/thermo-

stat supply line, manifold component block, manifold

tube, and pilot tube connections for leaks. Check for

leaks by brushing on an approved noncorrosive leak

detection solution. Bubbles forming indicate a leak.

Correct any leak found. IMPORTANT: All leaks must be

fixed immediately.

10. Replace the outer door.

DOOR GASKET

FLAME ARRESTOR COMBUSTION CHAMBE

BASE-RING

FILTER

FIGURE 33.