Internal threading – Sandvik Coromant Silent tools - users guide User Manual

Page 34

34

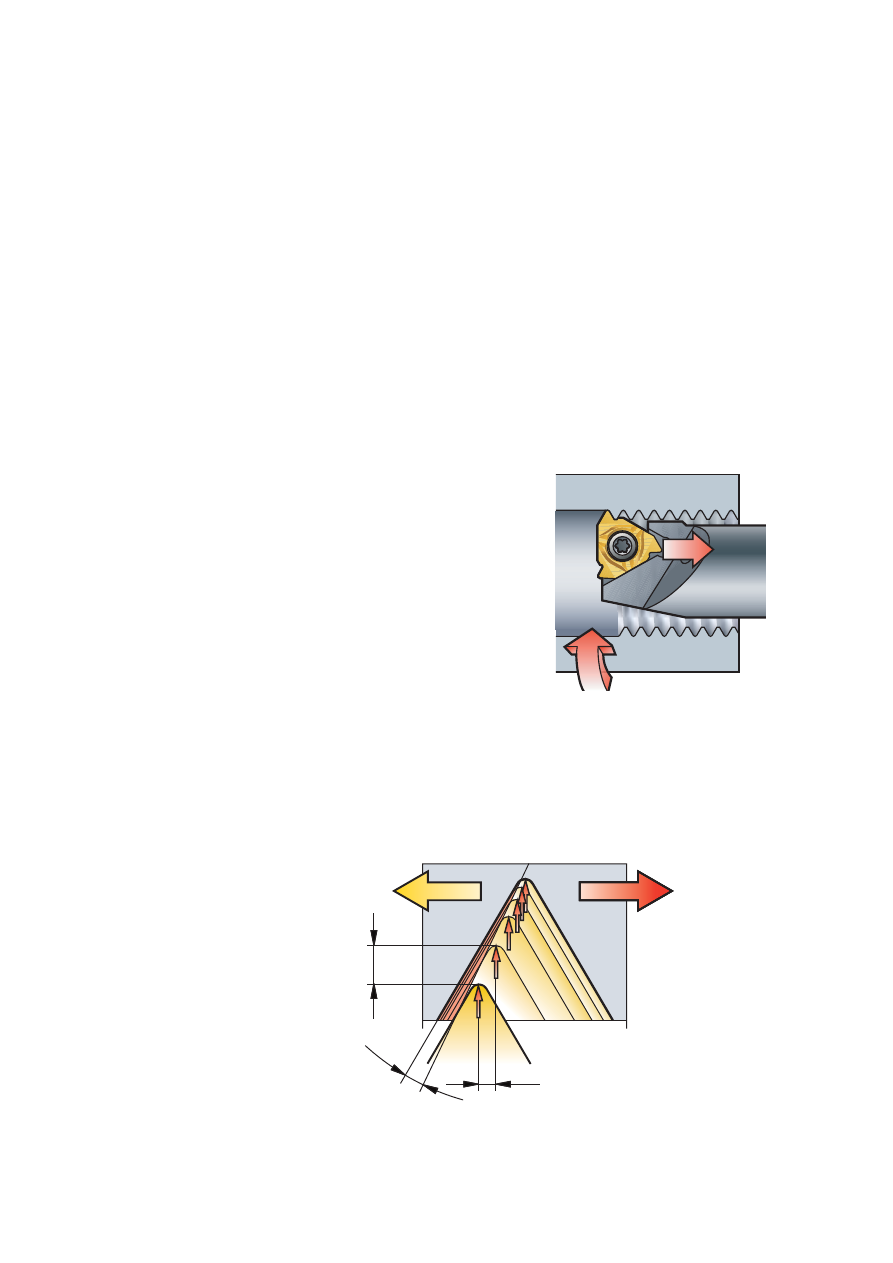

3-5°

0.5 x '

ap

'

ap

Feed direction from

inside out

Internal threading

Reduce risk of vibration:

• Use modified flank infeed.

• Infeed per pass should not exceed 0.2 mm and never

be less than 0.06 mm.

• Final pass always with infeed.

• Use a sharp geometry for lowest cutting forces.

Modified flank infeed

directs the chips out

from the hole

Feed direction

Chip direction

Chip evacuation:

• Use modified flank infeed to

lead the spiral chips towards the

opening of the hole.

• Use inside out feed direction for

best chip control.

• Use coolant for best chip

evacuation.

• Use a chip-breaking geometry.