Sandvik Coromant Silent tools - users guide User Manual

Page 33

33

Internal grooving and profiling

Reduce risk of vibration:

• Set-up should have the shortest possible overhang

with the lightest cutting geometry possible.

• Use a smaller insert and make several cuts instead

of one.

• Start from outside and make overlapping cuts inwards

for best chip evacuation.

• A finishing operation can be a side turning motion.

Start from inside and turn outwards.

• Ramping/turning can be used for improved chip

control and may reduce vibration.

• Use right- or left-hand style inserts to direct the chips

when roughing.

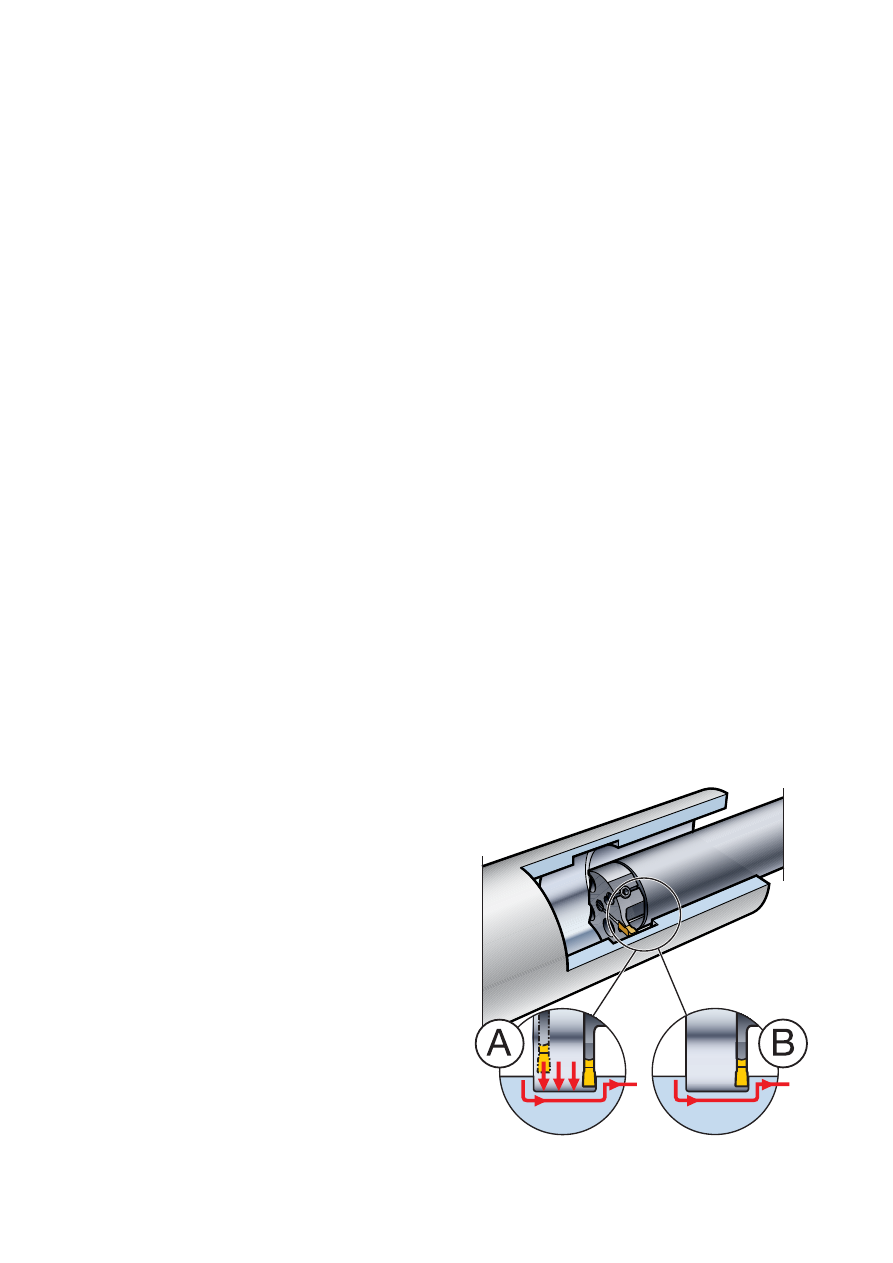

• Machine large-width

grooves using several

insertions with a

narrower insert

(illustration A).

• End with a finishing cut

(illustration B).