Important safety instructions, Requirements and warnings, Outback power systems, inc – Outback Power Systems FLEXware 250 - Users Guide User Manual

Page 5

IMPORTANT SAFETY INSTRUCTIONS

This manual contains important instructions for the FLEXware 250 that must be followed

during its installation and future maintenance for your safety and the integrity of the product.

SAVE THESE INSTRUCTIONS!

Requirements and Warnings

The OutBack Power Systems FLEXware 250 is listed by ETL as an accessory enclosure for

OutBack FX, GTFX, GVFX, and VFX Series Inverter/Chargers to UL standard UL 1741.

This enclosure is intended for battery circuits configured for 12 to 48 volts nominal.

Grounding Instructions – The frame of this enclosure should be connected to a grounded,

permanent wiring system. The AC and DC circuits are not bonded to the FLEXware 250

chassis. System grounding, when required by sections 690.41, 690.42, and 690.43 of the

National Electric Code, ANSI/NFPA 70, is the responsibility of the installer. For most installations,

the negative battery conductor should be bonded to the grounding system at one (and only

one) point in the DC system. All installations should comply with all national and local codes

and ordinances.

The equipment ground on FLEXware 250 is marked with this symbol:

FLEXware is designed for indoor mounting only with appropriate fasteners and a secure

mounting surface that can handle the full weight of an assembled system.

DWG. NO.

SCALE:

SHEET 1 of 1

Outback Power Systems, Inc

19009 62nd Ave. NE Arlington, WA 98223

www.outbackpower.com

TITLE:

DATE

NAME

ENG. APPR.

CHECKED

DRAWN

6/13/07

375-0095-01-00

Torque Label

Brian M.

Marianne M.

6/13/07

375-0095-01-98

PROPRIETARY AND CONFIDENTIAL

The information contained in this

document is the sole property of

Outback Power Systems, Inc. Any

reproduction in whole or in part

without the express written

consent of Outback Power

Systems, Inc is strictly prohibited.

Copyright (C) 2006 Outback Power

Systems, Inc. All Rights Reserved.

Reason for change:

Initial release, ECO114

Rev.

A

Notes:

1. Material is to be 2 mil poly. with L344

adhesive, and clear gloss laminate.

2.Text is PMS Black Arial font.

3. Dashed pink line represents perforation

line.

4. Solid pink line represents die cut line.

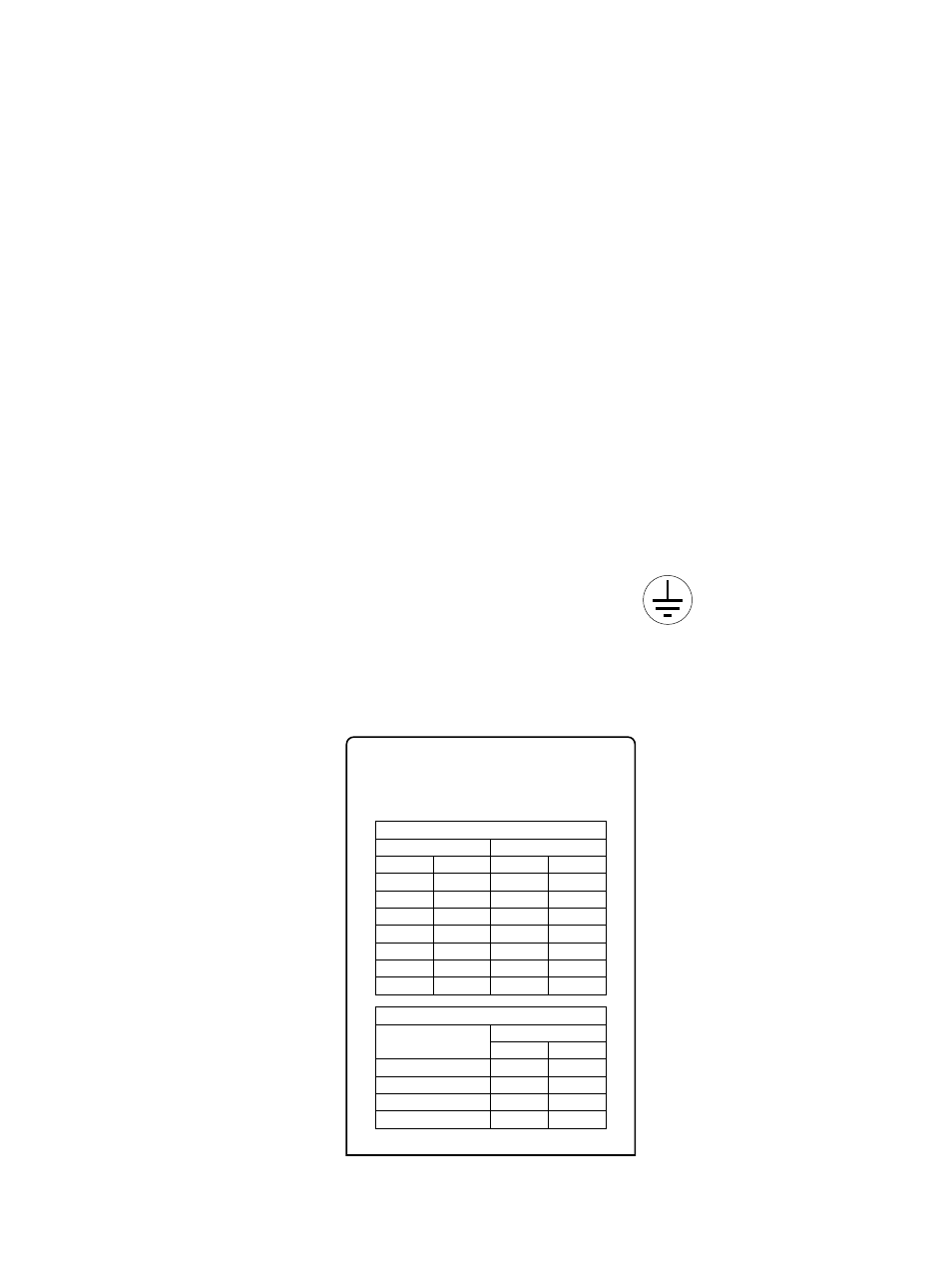

USE ONLY WITH COPPER

CONDUCTORS RATED

75° C

MINIMUM

TORQUE DATA FOR SCREWDRIVER LUGS

mm²

AWG

WIRE SIZE

TORQUE

In Lbs

Nm

TORQUE DATA FOR BREAKER LUGS

BREAKER STUD

TORQUE

In Lbs

Nm

14 - 10

8

6 - 4

3

2

1

1 / 0

2.1 - 5.3

8.4

13.3 - 21.2

26.7

33.6

42.4

53.5

20

25

35

35

40

50

50

2.3

2.8

4.0

4.0

4.5

5.7

5.7

20

2.3

35

4.0

50

5.7

225

25.5

1/4 - 20

M8

5/16 - 18

3/8 - 16

DIN RAIL MOUNTED BREAKER TERMINALS - 22 In Lbs

www.outbackpower.com

375-0095-01-00 REV A