Installation (cont’d) – Powerwinch Class 46' User Manual

Page 5

10. Two 1/4”-20 x 1/2” stainless steel nuts

11. 1” diameter heat shrink tubing

12. 2” diameter heat shrink tubing

13. ATO inline fuse holder

14. 10A ATO style fuse

15. Wire ties

16. Loctite® 242 thread locker (optional)

17. Silicone sealer

1. Place mounting template in desired

position on deck and secure with tape

into position. Ensure center-line of

gypsy lines up with centerline of davit

or bow roller.

IMPORTANT: Be certain anchor winch

is positioned above rope locker before

drilling any mounting holes. The anchor

line and chain will feed into rope locker

through a 2

1

/

2

” hole in boat deck and a

molded part called deck insert. Minimum

rope locker dimensions required for

proper storage of anchor lines are shown

in Chart 2.

2. Spot holes with center punch as

shown on template. Use an electric

drill to drill holes. There are three

11/

32

” holes for mounting studs, one 2

1

/

2

” hole for deck insert, and one 5/8”

hole for wiring harness.

3. Place round side of insert into 2

1

/

2

” hole

and seat deck insert so lip is flush with

boat deck. The half circle portion of

deck insert must be pointing toward

bow of boat.

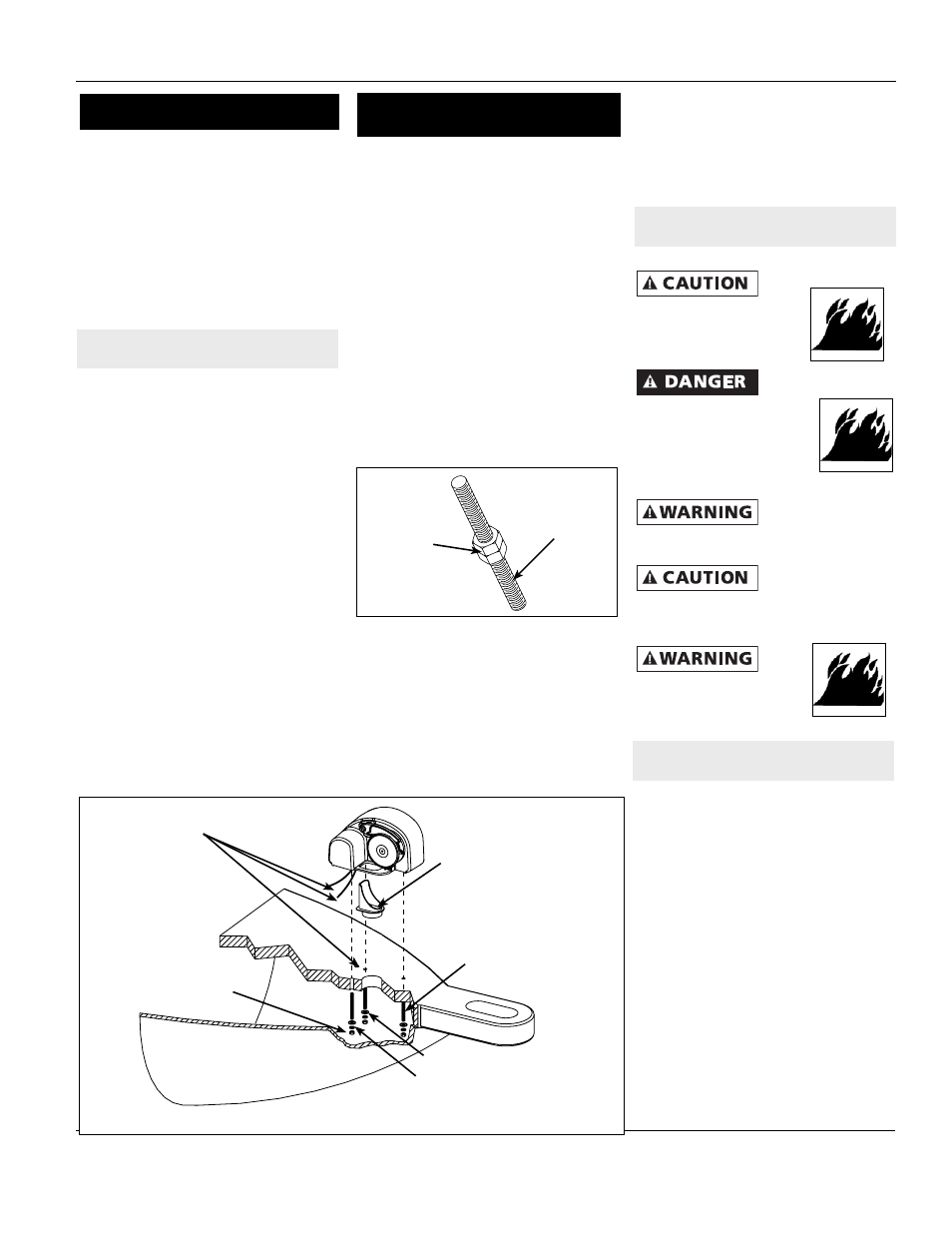

4. Insert three mounting studs into

threaded holes on underside of winch.

A small amount of thread locker can

be used to secure studs in housing.

Use two mounting nuts to help tighten

studs into housing as shown in Figure

5.

5. Gently guide winch over rode glide

so loop on anchor winch housing

slides over deck insert. Slide three

mounting studs into three mounting

holes in deck. Feed wiring harness

from underside of winch through 5/8”

hole.

6. The winch must fit squarely over

deck insert and onto deck. Slide

flat washers and lock washers onto

mounting studs. Tighten nuts to fully

secure winch to deck.

8. Examine winch to make sure unit is

securely fastened and that center-line

of gypsy is aligned with centerline of

bow roller or davit.

Do not use electrical wire

sizes or types other than

those specified or included

with this product.

Use supplied or recommended

circuit breakers for safe

installation. The warranty will

be void and fire could result

from using improper circuit

breakers.

Always disconnect

wiring harness from

battery before attempting to install, service

or relocate unit.

Follow order of

wiring steps to

ensure power is not applied to anchor

winch until all wires and circuit breakers

are installed.

Always keep wires away

from intense sources of heat.

Be sure newly installed wires

are away from any exposed bare wires.

1. Select a suitable location (console,

etc.) to locate switch. Make sure

there is enough room behind switch

mounting surface for entire switch

and wires.

2. Cut a hole 1

3

/

4

” high and 1” wide.

3. Apply a thin band of silicone sealer

around edge of switch mounting plate

and attach plate using four #8 round

head wood screws.

4. Select a suitable location for relay

(reversing switch). Locate reversing

switch within 6-8 feet of switch plate

and in a location away from exposure

to water. Mount relay with power

terminals facing up.

5

31’, 36’, 41’, 46’ Class Anchor Winch

LOCATING MOUNTING HOLES FOR

ANCHOR WINCH

WIRING AND SWITCH INSTALLATION

Installation (Cont’d)

Figure 4 - AW46’ Class

5/8” Hole in Deck for

Motor Lead Wires

Rode Glide

Lock Washer

Flat Washer

Hex Nut

Stud

NOTE: Mounting and gasket hardware

available in kits (P/N P10349 & P11162)

Line Locker

Dimensions Dimensions (L x W)

1/2” x 200’ 15” x 17”

1/2” x 300’ 15” x 24”

5/8” x 200’ 15” x 24”

5/8” x 300’ 16” x 32”

Chart 2

Figure 5

Mounting Stud

Mounting

Nuts

SWITCH AND SOLENOID LOCATION

18. four 3/8” 6-gauge female disconnects