Mc Leod Street Pro/Super Street Pro User Manual

Page 2

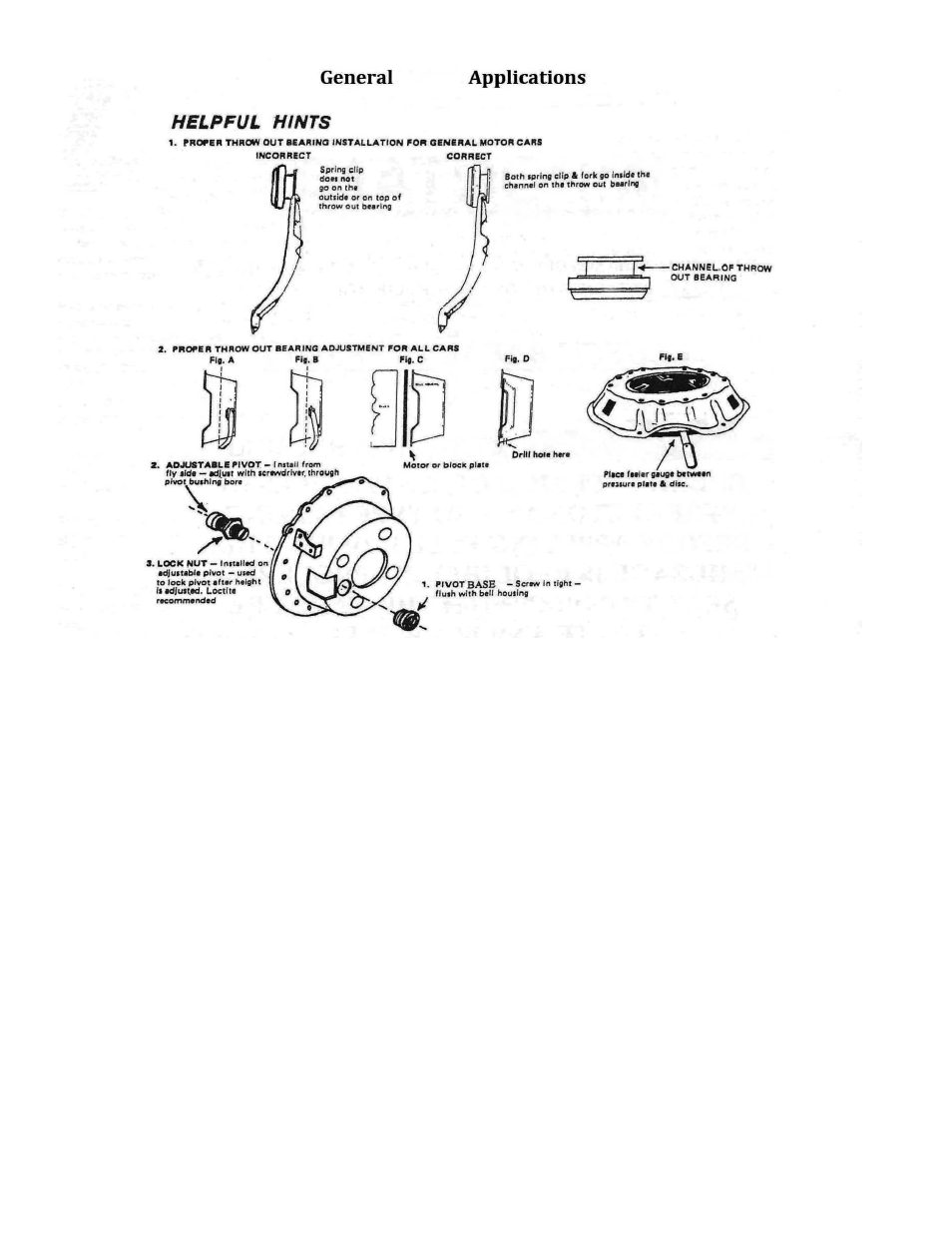

It is very important you follow proper installation procedures during clutch replacement; while second most important is

proper adjustment.

If you have a two-piece bell housing, throw out bearing adjustment is simple: just look into the bell housing and adjust the T.O.

Bearing off the pressure plate fingers ¼ inch (.250”).

If your bell housing is a full 360 degree bell housing, first determine whether or not your T.O. Bearing is of sufficient length

and is at the proper pivot angle. Disconnect the adjustment rod so that the fork is free. Move the fork by hand toward the

transmission until the T.O. bearing contacts the clutch pressure plate fingers. At this point, check the angle of the fork as it

comes out of the bell housing. It should be coming out straight or be slightly angled toward the engine. See Fig. A. If the angle

is toward the transmission, See Fig B, you are past the Center Line with the bearing and are losing all mechanical leverage. To

correct this problem, install a slightly longer T.O. bearing (with flat face)) or use an adjustable ball stud. Be sure to use the

McLeod Adjustable Length T. O. Bearing #16505 or its equivalent

When using a scatter shield with a motor plate or block plate, See Fig. C, use of an adjustable ball stud or intermediate T.O.

bearing is recommended. To ensure proper adjustment for release on most high performance or drag cars, a hole should be

drilled into the bell housing under the clutch assembly large enough to permit entry of a feeler gauge, See Fig D.

When adjusting with a feeler gauge, push the pedal all the way to the floor (or pedal stop); then, by adjusting the clutch rod,

slide the feeler gauge between the disc and pressure plate until you have .050” air gap, See Fig. E. When .050” is adjusted into

the clutch let the pedal up. Your clutch assembly should be properly adjusted.