Bell housing alignment procedure – Mc Leod Soft Lok User Manual

Page 4

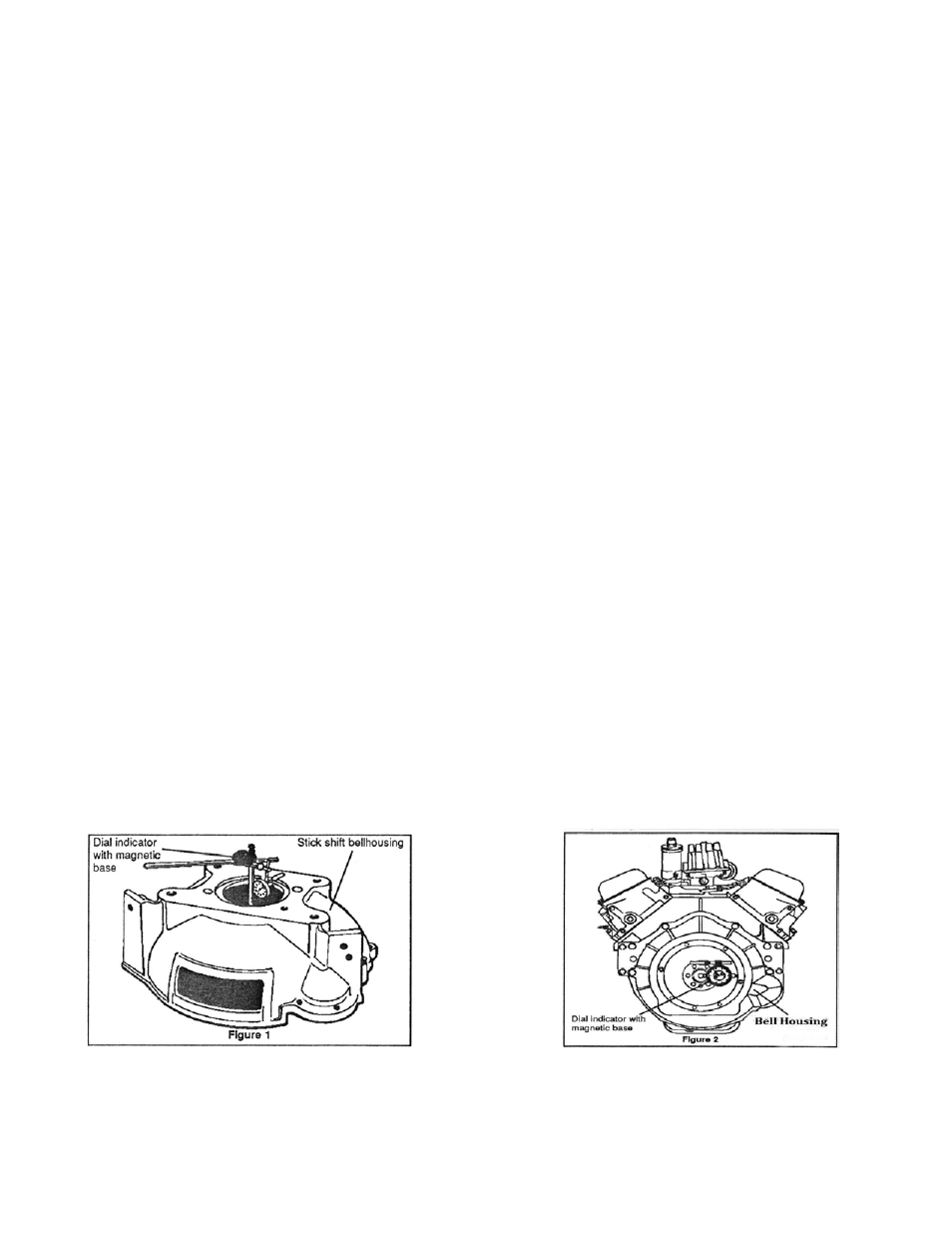

Bell Housing Alignment Procedure

When swapping a clutch, bell housing or

transmission it is highly recommended you check the

alignment of the bell housing to the engine

block/crankshaft and to the transmission input

shaft/output shaft. Think of this as a theoretical

straight line running through the crankshaft, through

the input shaft of the transmission and the output

shaft of the transmission. Misalignment along this

path can lead to leaks, poor clutch release, premature

wear of components and excessively noisy operation.

This inspection can be performed with a few common

measuring devices and some time.

Manufacturer’s tolerances of engine/crankshaft

alignment can vary especially if the engine block has

been modified throughout its lifetime or if you are

performing a bell housing and/or transmission swap.

If you find excess misalignment on your engine/bell

housing you can correct the problem with off-set

dowel pins. (Lakewood Industries offers Offset

dowel Pins to correct misalignment conditions). You

will need a dial indicator with a magnetic base along

with some typical hand tools to perform this

inspection. It is critical you pay close attention to

detail when performing this inspection in order to

achieve accurate assembly results.

1) Install flywheel onto crankshaft, using proper bolts and torque to factory setting.

2) Be certain the engine block dowel pins stick out of the rear of the engine block at least 3/8” for

proper bell housing engagement. Check the rear surface of the engine block at this time to be

certain it is free of nicks or burrs that will prevent the bell housing from seating against the block.

3) Install just the bell housing and hold in place with a few bolts. Install dial indicator base onto

crank flange or flywheel face and adjust plunger to contact the register bore of the bell housing.

Rotate the crankshaft and note the indicator reading as you sweep the register bore of the bell

housing.

4) Misalignment can be determined by dividing the change in the indicator by 2. Maximum allowable

runout is .005”.

5) If your reading exceeds .005” off-set dowel pins must be used to correct the misalignment.

Lakewood Industries offers such dowel pins in several sizes.

This alignment procedure will eliminate premature wear on many of the transmission and

clutch related components and will provide smoother operation.

I0029