Gauge connection, Limited one year warranty and service procedures, A. speedometer (figure 4) – Equus 8076 - 3-3/8 Mechanical MPH Speedometer User Manual

Page 2: B. hourmeter / clock (figure 5)

Copyright © 2012 IEC. All Rights Reserved.

The Manufacturer warrants to the original purchaser that this unit is free of defects

in materials and workmanship under normal use and maintenance for a period of

one (1) year from the date of original purchase. If the unit fails within the one (1) year

period, it will be repaired or replaced, at the Manufacturer’s option, at no charge,

when returned prepaid to the Service Center with Proof of Purchase. The sales

receipt may be used for this purpose. Installation labor is not covered under this war-

ranty. All replacement parts, whether new or remanufactured, assume as their war-

ranty period only the remaining time of this warranty. This warranty does not apply

to damage caused by improper use, accident, abuse, improper voltage, service, fire,

flood, lightning, or other acts of God, or if the product was altered or repaired by any-

one other than the Manufacturer’s Service Center. The Manufacturer, under no cir-

cumstances shall be liable for any consequential damages for breach of any written

warranty of this unit. This warranty gives you specific legal rights, and you may also

have rights, which vary from state to state. This manual is copyrighted with all rights

reserved. No portion of this document may be copied or reproduced by any means

without the express written permission of the Manufacturer. THIS WARRANTY IS

NOT TRANSFERABLE. For service, send via U.P.S. (if possible) prepaid to

Manufacturer. Allow 3-4 weeks for service/repair.

If you have any questions, require technical support or information on UPDATES and

OPTIONAL ACCESSORIES, please contact your local store, distributor or the

Service Center.

USA & Canada:

(800) 544-4124 (6am - 6pm,

7 days a week PST)

All others: (714) 241-6802 (6am - 6pm,

7 days a week PST)

FAX: (714) 432-

3979 (24 hr.)

Web: www.equus.com

Technical Service Center

17352 Von Karman Ave.

Irvine, CA 92614

LIMITED ONE YEAR WARRANTY AND SERVICE PROCEDURES

GAUGE CONNECTION

4

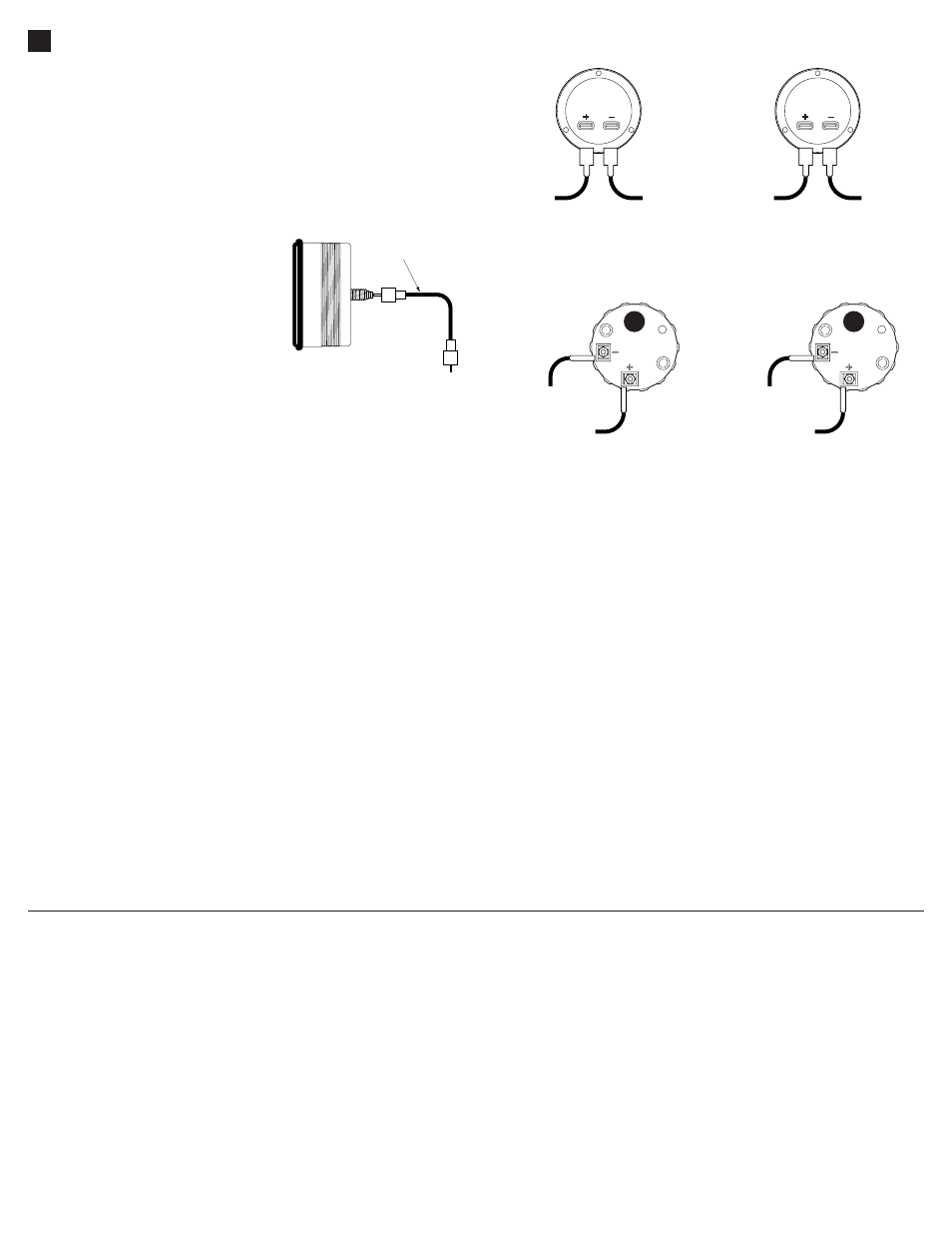

A. SPEEDOMETER (Figure 4)

Connection of the speedometer requires using the vehicle's existing

speedometer cable. Route existing speedometer cable to rear of speedo-

meter and connect cable to 5/8"–18 male connector on rear of speedome-

ter. If the cable drive and/or the female threaded connector from the vehicle's

speedometer cable does not fit, you must buy an adapter and/or replace the

speedo-meter cable. See IMPORTANT note below. Connection adapters

and cables are available from most speedometer shops.

IMPORTANT: The speedometer is de-

signed for a 1:1 drive ratio (60 mph or

96,5 km/h at 1000 RPM) using a 5/8"-18

cable thread shaft. This shaft requires a

0.104” (2,64 mm) square female cable

drive. If the vehicle’s tire size or differen-

tial ARE NOT stock (original), speedome-

ter accuracy will be affected. It may be

necessary to change to a different pinion

gear to achieve the required 60 MPH at

1,000 RPM.

TRIPMETER OPERATION

The speedometer is equipped with a four-

segment resetable Tripmeter. To reset the

Tripmeter, rotate the Tripmeter reset knob

counterclockwise until the Tripmeter shows "0000".

B. HOURMETER / CLOCK (Figure 5)

NOTE: Hourmeter / clock operating voltage is 10 VDC minimum to 80 VDC

maximum (polarity-sensitive).

NOTE: Lead wires must be purchased separately. Use 16 - 18 AWG wire

minimum.

1.

Determine routing for gauge lead wires. Use an existing firewall grom-

met, or drill a 3/8" (9.5 mm) hole through firewall to accommodate lead

wires. Install a rubber grommet (purchased separately) in hole, and

use shrink tubing to protect lead wires from chaffing or other damage.

2.

Install and crimp or solder 1/4" female spade connectors (purchased

separately) on gauge positive (+) and negative (-) lead wires.

3.

Connect lead wires to hourmeter or clock positive (+) and negative (-)

spade posts. Route lead wires through grommet in firewall.

4.

Connect free ends of hourmeter or clock lead wires to vehicle electri-

cal system:

HOURMETER

For Negative Ground Systems

■

Connect hourmeter positive lead wire to a switched voltage source

in the vehicle electrical system.

■

Connect hourmeter negative lead wire to a good bare metal chas-

sis ground.

For Positive Ground Systems

■

Connect hourmeter negative lead wire to a switched voltage

source in the vehicle electrical system.

■

Connect hourmeter positive lead wire to a good bare metal chas-

sis ground.

CLOCK

For Negative Ground Systems

■

Connect clock positive lead wire to an unswitched (constant) volt-

age source in the vehicle electrical system.

■

Connect clock negative lead wire to a good bare metal chassis

ground.

For Positive Ground Systems

■

Connect clock negative lead wire to an unswitched (constant) volt-

age source in the vehicle electrical system.

■

Connect clock positive lead wire to a good bare metal chassis

ground.

5.

Secure lead wires along their route to prevent damage from sharp

edges, moving parts or hot engine components.

6.

Reconnect negative (-) battery cable.

■

For Hourmeter: Start and run engine for several minutes and ver-

ify hourmeter accumulates operating time.

■

For Clock: Observe clock for several minutes and verify time

advances.

EXISTING

SPEEDOMETER

CABLE

Figure 4

TO VOLTAGE

SOURCE

TO VOLTAGE

SOURCE

TO CHASSIS

GROUND

TO CHASSIS

GROUND

NEGATIVE GROUND SYSTEM

POSITIVE GROUND SYSTEM

TO

VOLTAGE

SOURCE

TO

VOLTAGE

SOURCE

TO

CHASSIS

GROUND

TO

CHASSIS

GROUND

NEGATIVE GROUND SYSTEM

HOURMETER CONNECTION

CLOCK CONNECTION

POSITIVE GROUND SYSTEM

Figure 5