Equus 8468 - 2-5/8 Voltmeter User Manual

Installation instructions mechanical gauges/kits, Preparation for installation, Mounting and installation

INSTALLATION INSTRUCTIONS

MECHANICAL GAUGES/KITS

PREPARATION FOR INSTALLATION

1

© 2004 IEC - All Rights Reserved

MRP #93-0010 Rev. B

VOLTMETER

OIL PRESSURE

TEMPERATURE

This section

must be read and followed before installation of the gauge is

performed.

1. Read instructions completely before installation.

2. Install gauges only when engine is cool and ignition is off.

3. Make sure all necessary tools, materials, and parts are on hand.

4. Always read the vehicle's service manual and follow it’s safety precautions

before any test or service procedure is performed.

5. Disconnect negative (-) battery cable before installing gauges (do not for-

get to reconnect battery after installation is complete).

6. Locate the vehicle's oil pressure and/or coolant temperature sending units,

and verify the vehicle's sending unit port thread size is compatible with the

thread size on the gauge's sending unit and/or the supplied adapters. DO

NOT DRILL ANY HOLES IN DASH BEFORE ENSURING COMPATIBILITY.

See the following notes.

NOTES:

■

If the vehicle's original temperature sending unit is used by the computer

for engine control functions, DO NOT REPLACE. Consult the dealer (or a

professional) to determine if the new sending unit can be installed in an

alternate location on the engine. If no suitable location is found, this gauge

is not suitable for your application. (See below for oil pressure gauge.)

■

For oil pressure gauges, a T-fitting (sold separately) may be used to

accommodate the new gauge sending unit, and to keep the vehicle's

original sender operational.

7. Determine a mounting location for the gauge. Choose a location that does

not impair visibility or interfere with driving. Check behind the mounting

location for any wiring or components before drilling. Also take into consid-

eration the routing and length of the lead wires, nylon tubing and/or the cap-

illary tube from gauge to engine sender port.

WARNING: Follow vehicle manufacturer’s service recommendations.

Check and maintain the vehicle’s engine regularly (cooling system level

and condition, oil system level and condition, charging system condition,

etc.). Never rely on the gauges as the ONLY means of protection.

NOTE: For information on optional mounting configurations and mounting

hardware, visit us on the web at www.iequus.com

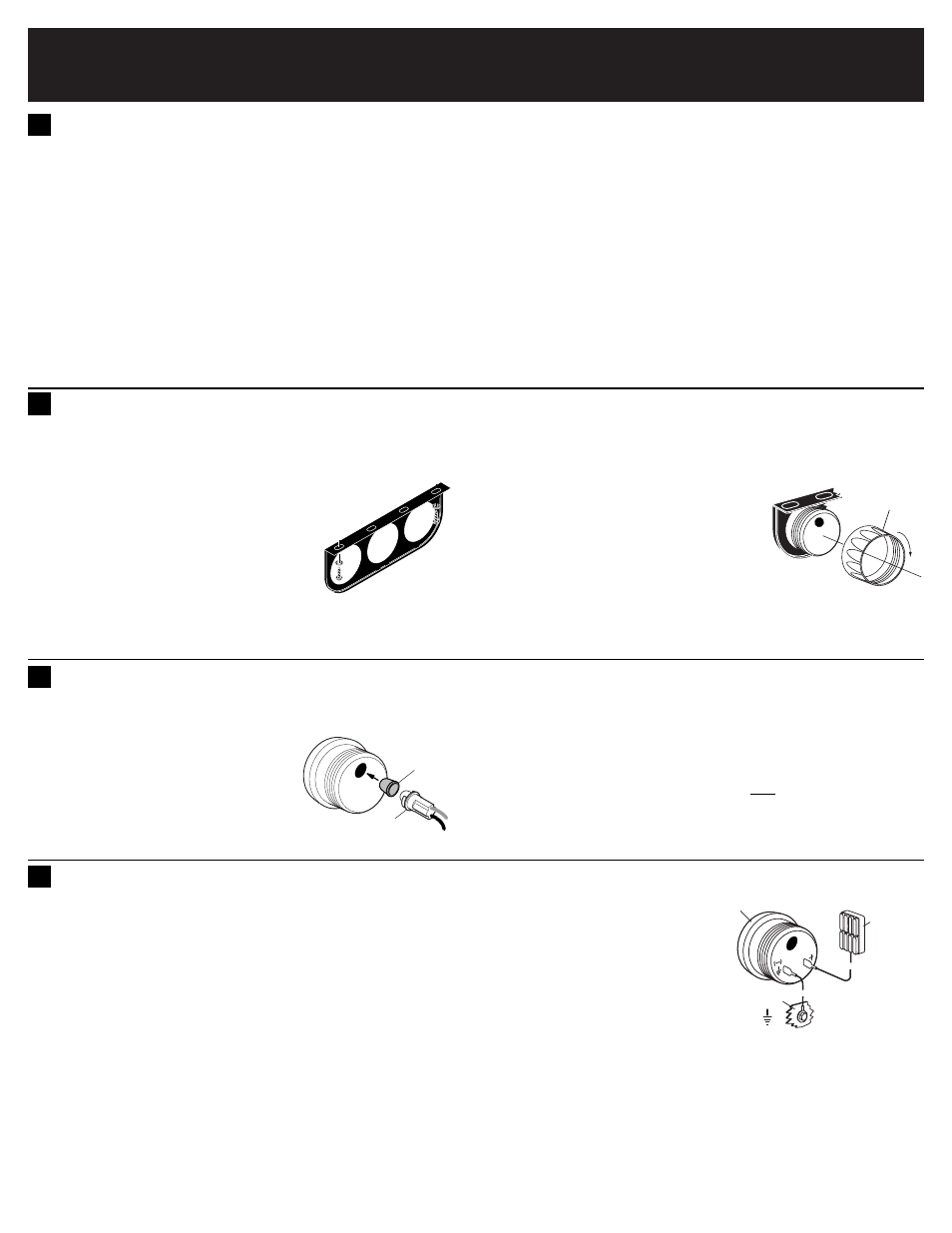

A. PANEL INSTALLATION

For On-Dash or Under-Dash mounting (panels

are optional with some gauge models and

must be purchased separately).

1. Determine mounting location (see section 1,

step 7).

2. Using gauge panel as a template, mark loca-

tions for screws.

3. Drill small holes for the screws.

4. Mount panel in place and secure with screws

and flat washers provided.

MOUNTING AND INSTALLATION

2

B. IN-DASH MOUNTING

1. Using a hole template, cut out a 1-1/2", 2" or 2-5/8" (3.81 cm, 5.08 cm, or 6.67

cm) hole, as necessary, through the dashboard.

2. Using a round file, smooth out the rough edges around the drilled hole.

C. INSTALLING GAUGE INTO GAUGE

PANEL OR IN-DASH

1. Insert gauge through front of panel or hole in

dashboard, as applicable.

2. Hold gauge case and rotate gauge, as need-

ed, until gauge dial face is properly posi-

tioned in front of dashboard/panel. Secure

gauge in place.

3. Tighten locking ring on gauge in clockwise

direction until gauge is tight against dash-

board/panel. Tighten locking ring HAND

TIGHT ONLY.

Figure 1. Gauge Panel

LOCKING RING

Figure 2. Gauge Equipped

with Locking Ring

NOTE: Depending on the model of gauge, backlighting color may be changed

to either red, green or blue by installing the optional color filter over the bulb

(not available for all gauge kits).

1. Insert the light bulb and socket assemblies

into the light receptacles on the back of the

gauge and press firmly to snap/lock into

place.

NOTE: Wire for gauge lights must be pur-

chased separately. Use size 18-20 AWG

stranded copper wire.

GAUGE LIGHT INSTALLATION AND CONNECTION

3

2. Splice the RED or WHITE wire from the gauge light(s) into the vehicle's

lighting circuit, between the dimmer control switch and the dash lights (con-

sult the vehicle's service manual for proper wire).

3. Connect light socket BLACK wire to a good chassis ground.

4. Insulate all connections with shrink tubing to prevent shorting.

WARNING: For bulb replacement use only part # 161 Instrument/

Indicator wedge type bulbs available at most auto parts stores. DO

NOT USE ANY OTHER PART NUMBER SINCE THE HEAT PRODUCED

BY A HIGHER WATTAGE BULB WILL MELT THE GAUGE CASE AND

CREATE A FIRE HAZARD.

BULB AND

SOCKET ASSEMBLY

OPTIONAL COLOR

FILTER

Figure 3. Light Bulb Installation

GAUGE CONNECTION

4

A. VOLTMETER

1. Using a multimeter or test light, find a 12-volt positive (+) location that is hot

ONLY when the ignition key is in the "ON" position (possible locations: fuse

panel accessory, radio and cigarette lighter circuits).

NOTE: Wire must be purchased separately. Use 18-20 AWG stranded cop-

per wire.

2. Crimp or solder ¼" (6.35 mm) female spade/ring terminals (included) on

one end of voltmeter positive (+) and negative (-) wires, and connect wires

to voltmeter positive (+) and negative (-) terminal ring/spade posts, as appli-

cable.

3. Connect voltmeter positive (+) wire to an accessory location or line as

described in step 1.

4. Connect voltmeter negative (-) wire to a good bare metal chassis ground on

the vehicle.

NOTE: To prevent electrical shorts, route wires away from sharp edges and

parts. Insulate all splices with shrink tubing.

5. Reconnect the negative (-) battery

cable. With the ignition switch in

the "ON" position and engine NOT

RUNNING, voltmeter should read

between 12.5 and 13.2 volts. A

lower reading indicates a low bat-

tery, a poor connection or

dirty/defective battery cables.

6. Start and run engine. Voltmeter

should read between 13.3 and

15.2 volts (specifications vary,

consult your vehicle's service

manual for proper specifications). A lower reading can indicate a faulty volt-

age regulator, slipping belts, faulty alternator/battery, a poor connection or

excessive loads. A higher reading can indicate a faulty voltage regulator.

NOTE: If voltmeter fails to read, make sure positive (+) and negative (-)

connections on rear of gauge match. If voltmeter still fails to read, recheck

and tighten all connections.

VOLT METER

GAUGE

SWITCHED +12V

(FUSE BOX)

CHASSIS

GROUND

RED

BLACK

Figure 4. Voltmeter Connections

2.0

2.0

- 8454 - 2-5/8 Oil Pressure Gauge 8453 - 2-5/8 Water Temperature Gauge 8444 - 2-5/8 Mechanical Oil Pressure Gauge 8442 - 2-5/8 Mechanical Water Temperature Gauge 8268 - 2 Voltmeter 8262 - 2 Electric Water Temperature Gauge 8244 - 2 Mechanical Oil Pressure Gauge 8242 - 2 Mechanical Water Temperature Gauge 8200 - 2 Chrome Volt Triple Gauge Kit 8164 - 1-1/2 Electric Oil Pressure Gauge 8100 - 1-1/2 Volt Triple Gauge Kit 7268 - 2 Chrome Voltmeter 7244 - 2 Chrome Mechanical Oil Pressure Gauge 7242 - 2 Chrome Mechanical Water Temperature Gauge 7241 - 2 Chrome Mechanical Water Temperature Gauge 7234 - 2 Chrome Mechanical Oil Pressure Gauge 7232 - 2 Chrome Mechanical Water Temperature Gauge 7200 - 2 Chrome Volt Triple Gauge Kit 7068 - 3-3/8 Chrome Tachometer 6268 - 2 Black Voltmeter 6262 - 2 Electric Water Temperature Gauge 6244 - 2 Mechanical Oil Pressure Gauge 6242 - 2 Mechanical Water Temperature Gauge 6234 - 2 Mechanical Oil Pressure Gauge 6232 - 2 Mechanical Water Temperature Gauge 6200 - 2 Volt Triple Gauge Kit 6100 - 1-1/2 Volt Triple Gauge Kit