Water Inc wi-hp9100-TS Upflou User Manual

Page 3

Water Pressure

A minimum of 25 pounds of water pressure is required for

regeneration valve to operate effectively.

Electrical Facilities

A continuous 115 volt, 60 Hertz current supply is required.

Make certain the current supply is always hot and cannot be

turned off with another switch.

Existing Plumbing

Condition of existing plumbing should be free from lime and

iron buildup. Piping that is built up heavily with lime and/or iron

should be replaced. If piping is clogged with iron, a separate

iron filter unit should be installed ahead of the water softener.

Location Of Softener And Drain

The softener should be located close to a drain.

Bypass Valves

Always provide for the installation of a bypass valve.

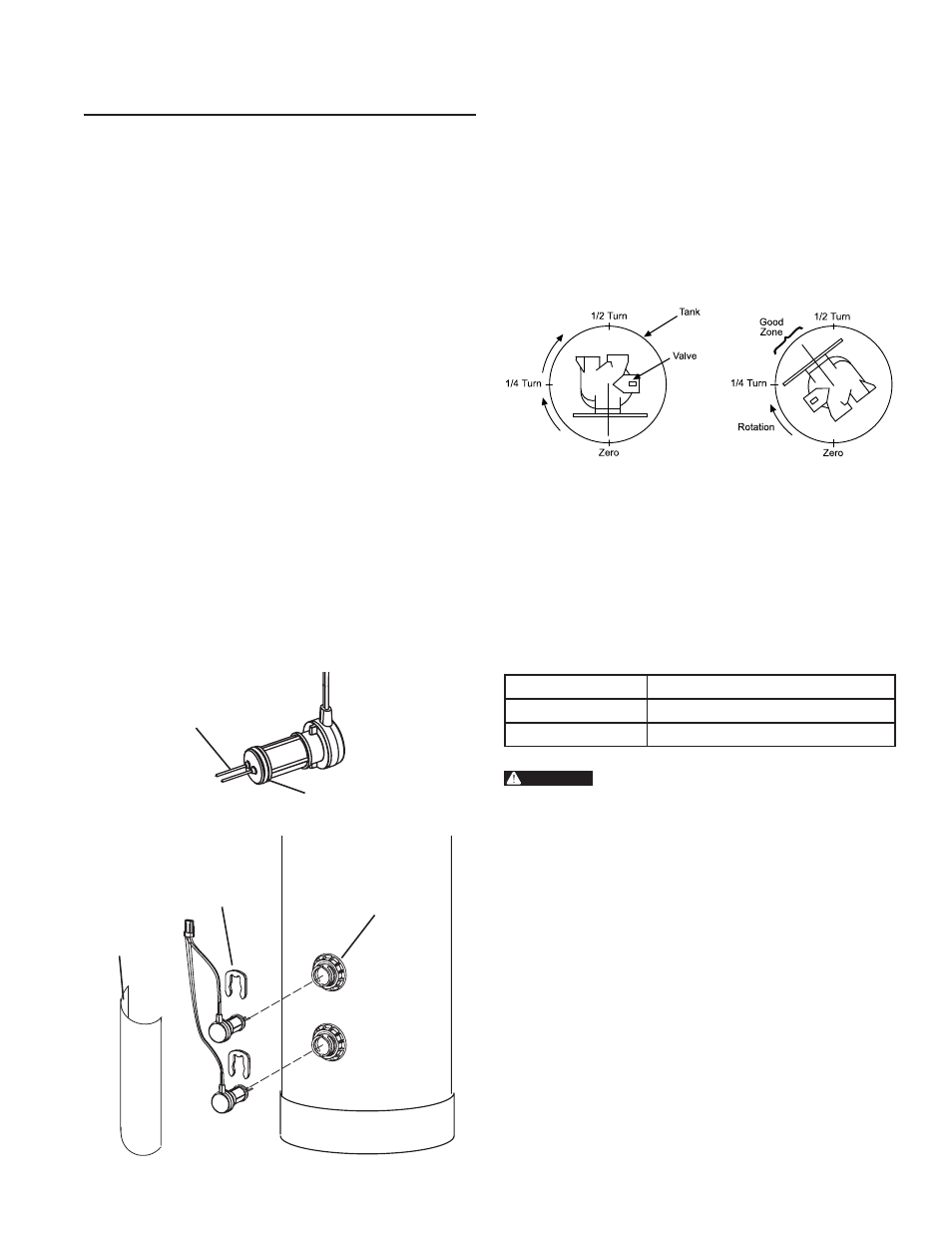

Tank and Probe Assembly

Use only 100% silicone lubricant on the probe O-rings

(Figure 2). Do not allow the lubricant to come into contact with

the probe pins. Install the probe assemblies into the tank and

secure with the locking clasp (Figure 3).

Important: The pins on the probes will only fit into the bulkhead

fittings one way. The pins must go into the matching holes at

the bottom of the fitting. The probe with the shortest length of

wire must be on top. Install the protective shield (Figure 3).

NOTE: Do not attempt to tighten or loosen the Bulkhead

fittings as they are secured with a locking

adhesive.

Lubricate

Probe Pins

Figure 2

Locking Clasp

Bulkhead Fitting

Protective

Shield

Figure 3

GENERAL AND COMMERCIAL

INSTALLATION INSTRUCTIONS

continued

Valve to Tank Installation Instructions

1. Spin the valve onto the tank, ensuring the threads are not

cross-threaded.

NOTE: All Fleck® valves are right-hand threads, or

clockwise, to install.

2. Rotate the valve freely without using force until it comes to

a stop (this position is considered zero).

3. Rotate the valve clockwise from zero, between ¼ turn and

½ turn (Figure 4).

Figure 4

NOTE: If lubricant is required, a silicone compound

is strongly recommended. Dow Corning®

Silicone Compound (available from Fleck®), is

recommended for best possible results. Dow

Corning® 7 Release Compound is used in the

manufacture of Fleck® control valves. The use of

other types of lubricants may attack the control’s

plastic or rubber components. Petroleum-based

lubricants can cause swelling in rubber parts,

including O-rings and seals.

Part No.

Description

16174

Silicone, 2 oz Tube

16586-8

Silicone, Dow #7 8 LB

WARNING:

Do not exceed water pressure of 125 psi

(8.6 bar). Do not exceed 110°F (43.3°C). Do

not subject unit to freezing conditions.

9100 TS Control Operation

Power Loss Memory Retention

The 9100 TS control features battery-free Time of Day and

Day of Week retention during temporary loss of power. A super

capacitor is designed to keep time for 8 to 24 hours depending

on the installation. If the super capacitor is exhausted the 9100

TS control will display four dashes (- - : - - ) immediately upon

power up. The Time of Day and Day of Week must be reset.

All other programmed parameters are stored in the static

memory and are retained.

9100 TS Upflow JA11 • 3