Adjusting buttonholes, Sewing buttons – Brother XL-5600 User Manual

Page 34

33

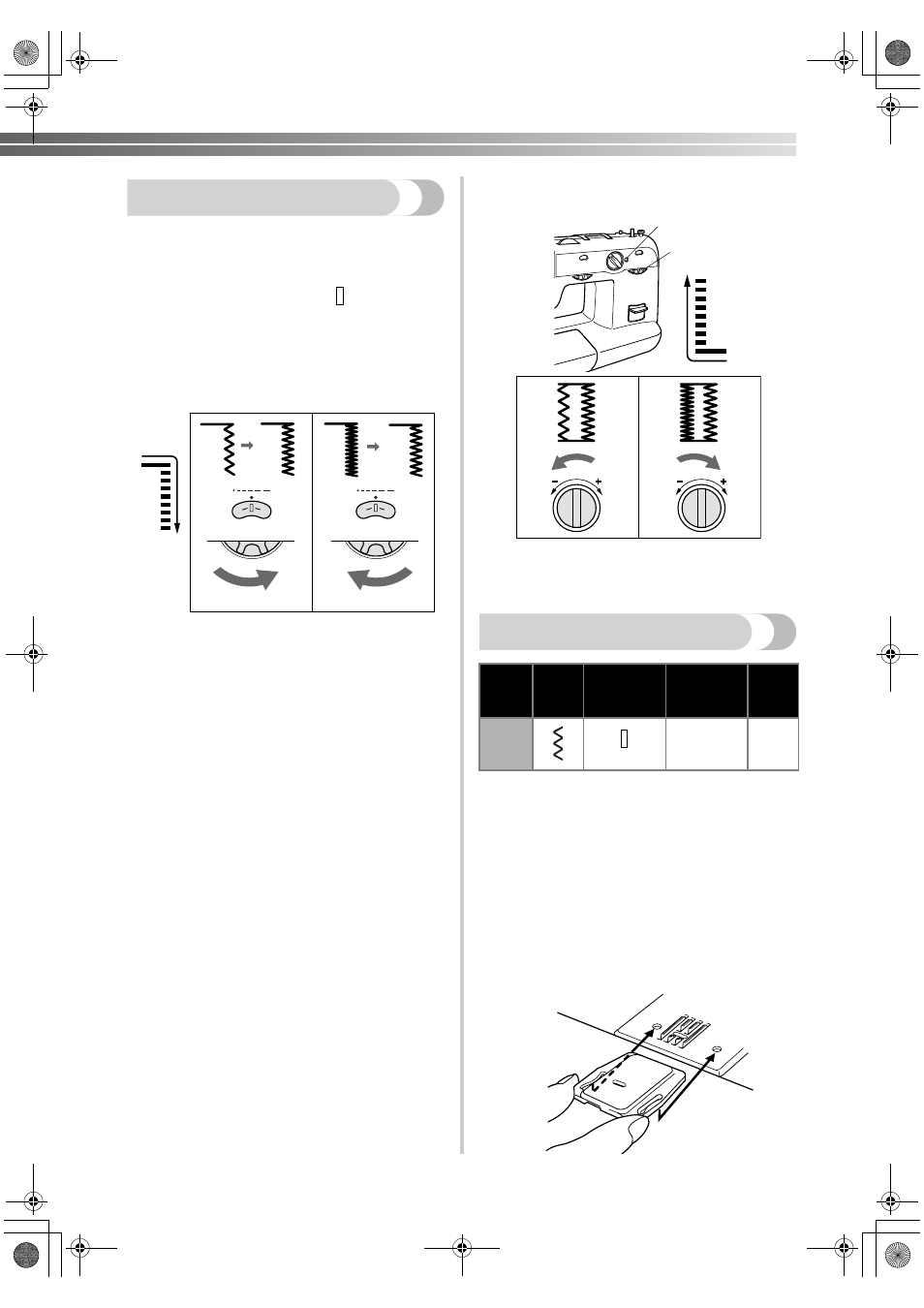

Adjusting Buttonholes

If the stitching on the two sides of the buttonhole is

not the same, you can make the following

adjustments.

1

Set the stitch length dial to " " and sew the

buttonhole on a scrap piece of fabric to

observe how the material is fed.

2

If the right side of the buttonhole is too coarse

or fine, adjust the feeding of the material with

the Stitch Length Dial.

1 Right side

2 Shorter

3 Longer

3

After obtaining a satisfactory feeding on the

right side, stitch the buttonhole and observe

the feeding.

4

If the left side is too coarse or fine compared

with the right side, adjust the buttonhole fine

adjustment screw as described below.

If the left side is too coarse, turn the buttonhole

fine adjustment screw with a large screwdriver

in the - direction.

If the left side is too fine, turn the buttonhole

fine adjustment screw with a large screwdriver

in the + direction.

• This adjustment ensures both sides of the

buttonhole are the same.

1 Stitch length dial

2 Buttonhole fine adjustment screw

3 Left side

4 In this case

Sewing Buttons

1

Measure the distance between the holes and

set the appropriate stitch width using the

stitch width dial. For example, if the distance

between the holes is 1.5 mm (1/16"), set the

stitch width to “1.5”.

2

Attach the button sewing foot.

3

Place the darning plate on the needle plate.

(On a machine equipped with a drop feed

lever, lower the feed dogs by setting the drop

feed lever to the up position.)

1

2

3

0

2

1

2

3

2

2

0

1

0

1

Stitch

Name Pattern

Stitch

Length

[mm (inch)]

Stitch

Width

[mm (inch)]

Foot

Zigzag

Stitch

(1/64)

Any

Button

Sewing

Foot

3

4

4

1

2

XL5000us.book Page 33 Tuesday, October 28, 2003 11:01 AM