UEi Test Instruments C75OILKIT User Manual

Page 9

C75-MAN

P. 7

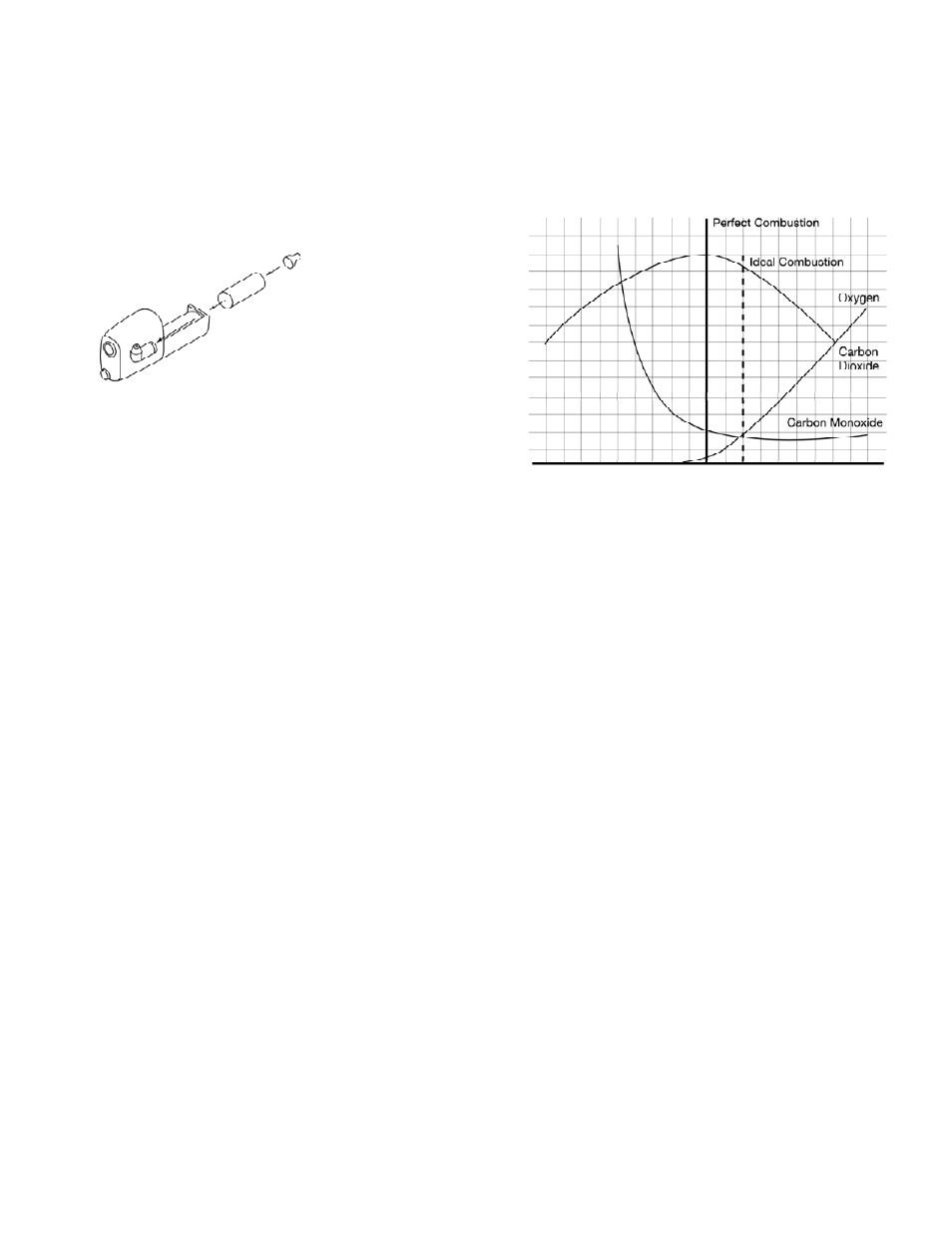

Below is a graph of typical combustion, showing the point of perfect

combustion and an approximate location for ideal combustion. You will

notice that by moving farther to the right on the air rich side (high

amounts of excess air), the pollutants (CO) don’t drop any further. This

is where you only lower efficiency. On the left side (fuel rich or starved

for air) you see a dramatic increase in carbon monoxide (CO), indicat-

ing that a portion of the fuel is not being converted to heat.

Combustion Efficiency Calculation

The efficiency calculation is based upon British Standards BS845.

This identifies three sources of loss associated with fuel burning:

Losses due to flue gasses:

Dry Flue gas loss, moisture and

hydrogen, sensible heat of water

vapor, unburned gas

Losses due to refuse:

Combustible in ash, riddlings

and dust

Other losses:

Radiation, convection, conduction

other unmeasured losses

Since the fuel air mixture is never consistent there is the possibility of

unburned/partially unburned fuel passing through the flue. This is rep-

resented by the unburned carbon loss.

Losses due to combustible matter in ashes, riddlings, dust and grit,

radiation, convection and conduction are not included.

If condensate spills onto the skin or clothing, clean off immediately

using fresh water, seek medical advice if problems occur. Ensure plug is

replaced before performing combustion tests.

Changing the Particle Filter

This is a very important part of the analyzer and should be changed reg-

ularly. It prevents dust and dirt particles from entering the pump and

sensors that will cause damage. The filter MUST be changed when it

appears discolored.

Remove water-trap assembly from the analyzer as shown above.

Remove the filter and plastic holder from the housing. Discard the filter

element but keep the holder to fit to the new filter. Clean the inside of

the filter housing with a suitable soft cloth. Fit the holder onto the new

filter element and then insert into the housing. Refit the housing onto

the analyzer.

C o m b u s t i o n

Combustion Theory

In its simplest form, combustion is the combining of oxygen (O

2

) from

the air with hydrogen (H) and carbon (C) from the fuel to form carbon

dioxide (CO

2

), water (H

2

O) and energy (light and heat).

Perfect combustion occurs when all of the carbon and hydrogen in the

fuel unite with all of the oxygen supplied by the air. This is also referred

to as “STOICHIOMETRIC Combustion”.

In the real world perfect combustion is nearly impossible to achieve.

When tuning a combustion appliance, the goal is to come close to this

target to minimize losses and excess emissions. One method is to adjust

the amount of air supplied to the combustion area. Too little combus-

tion air, and there will not be enough oxygen to unite with the hydrogen

and carbon. This will result in partially burnt fuel, and the creation of

carbon monoxide (CO), smoke, and lower efficiency. Too much air will

also lower efficiency because the high amount of excess air draws heat

away from the combustion area up the flue (increase in ∆T, difference

between flue temperature and ambient or inlet). If the amount of excess

air is too high, it will also move past the heat exchanger too quickly,

resulting in a lower amount of heat transferring to the target.

Insert a new filter

Rich

Lean