Timeguard FFM250 User Manual

Page 3

3. Preparation of Surface

4. Planning Mat/Cable Layout

Wood Floor

This will generally be either floorboards or chipboard panels. With floorboards

any loose boards will need to be firmly fixed and it will be necessary to cover

the complete floor with 20mm plywood sheeting fixed at 200mm centres.

With chipboard panels ensure they are all firmly fixed and cover with plywood

as above. The use of a primer recommended by your screed/adhesive supplier

is essential. This must be applied to the complete floor surface to be tiled.

Grooves will need to be made to accommodate the cable/mat flying lead

(cold cable) and the temperature probe with its flying lead as these are

thicker than the heating cables (mat or cable).

Concrete/Screed Floor

Repair any fissures or patches with a cement sand mixture with PVA added to

improve adhesion. The use of a primer recommended by your screed/adhesive

supplier is essential. This must be applied to the complete floor surface to

be tiled.

Grooves will need to be made to accommodate the cable/mat flying lead (cold

cable) and the temperature probe with its flying lead as these are thicker than

the heating cables (mat or cable).

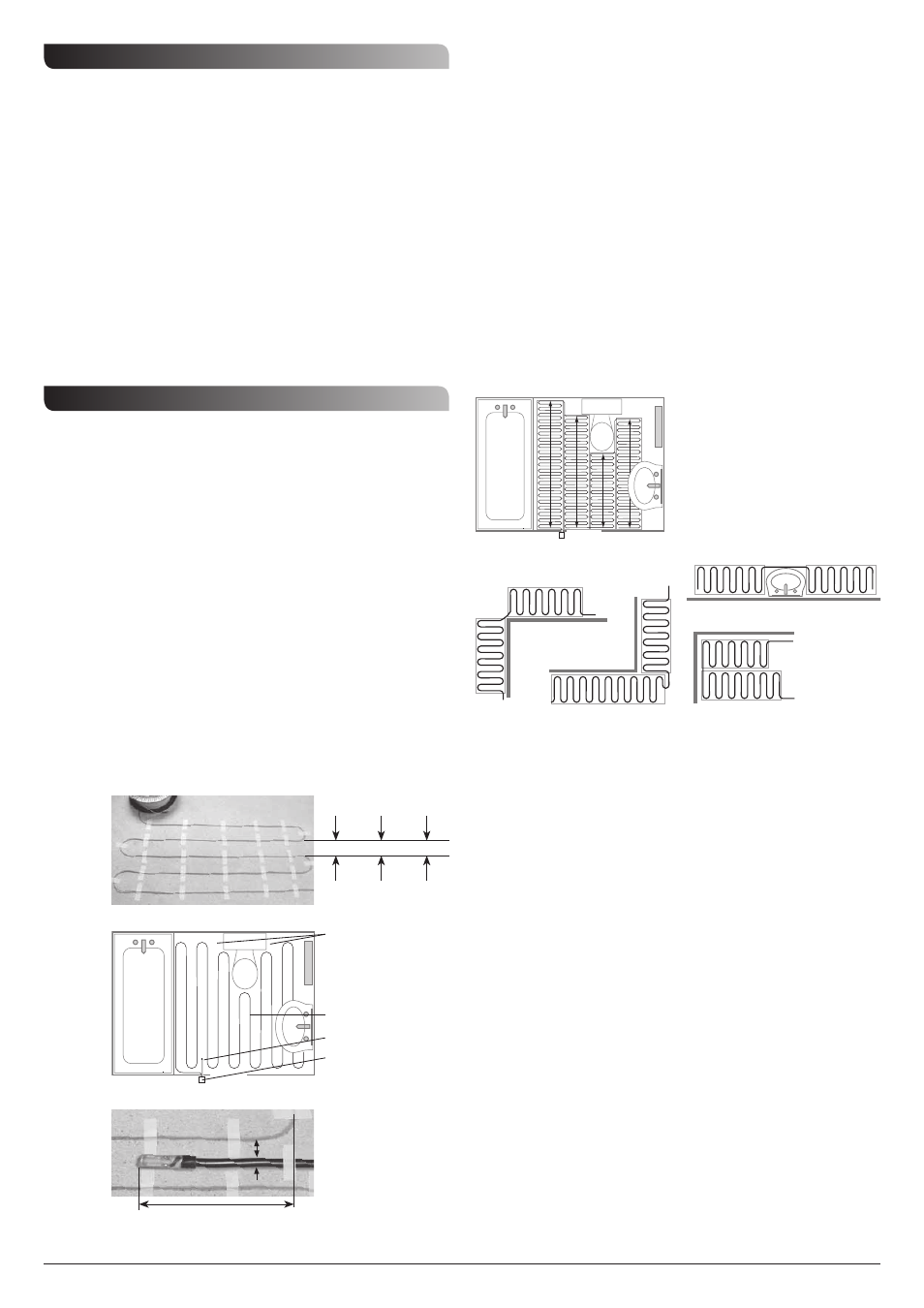

Figure 2

Figure 4

Figure 3

Cable Layout

The layout and installation of mat/cable must be carried out in accordance

with these instructions. If there is any doubt about how to proceed please

contact the Helpline on 020 8450 0515 or a competent professional person.

For wood floors the gap between the cable runs should be 82mm (see figure 1).

This gives 120W/m

2

. For concrete/screed floors the gap between cable runs

should be 62mm, this gives 160W/m

2

. To give 200W/m

2

the gap between cable

runs should be 50mm.

Initially decide on a location for the RCD and controller* then plan the run of

the cold cable to the start of the heating cable and the run of the temperature

probe flying lead, remembering that no cable should cross over or under any

other or the temperature probe which should be positioned as in figure 3.

The cold cable and probe flying lead are 4m long and may be shortened

if necessary.

Cables should be run backwards and forwards between walls or obstructions

(see the example given in figure 2). Cables should not be run under

permanent fixtures. The cables should not get closer to the tiling edge than

50mm and should clear permanent fixtures by the same amount.

If the largest cable in the range is not long enough a second cable can be used

with the two cold cables connected to the controller – black to black to

controller live output and blue to blue to controller neutral output.

* These should not be located in a bathroom or near a sink or cooking facilities in a kitchen.

Mat Layout

These have a fixed output of 160W/m

2

and are suitable for concrete/

screed floors.

Initially decide on a location for the RCD and controller* then plan the run of

the cold cable to the start of the heating mat and the run of the temperature

probe flying lead remembering that no cable should run under or over any

other or the temperature probe which should be positioned as in figure 3.

The cold cable and probe flying lead (both 4m in length) may be shortened

as necessary.

Mats should run backwards and forwards between walls or obstructions. The

techniques shown in figures 4 and 5 may prove useful. When cutting the mat

webbing to give direction changes or bypassing of obstacles take care not to

cut or damage the heating cable. Mat runs should be separated by at least

30mm and should not be run under permanent fixtures. The cables within the

mats should not get closer to the tiling edge than 50mm and should clear

permanent fixtures by the same amount. If the longest mat in the range is not

long enough to cover the required area a second mat or cable can be used

with the two cold cables connected to the controller controller – black to black

to controller live output and blue to blue to controller neutral output.

* These should not be located in a bathroom or near a sink or cooking facilities in a kitchen.

A groove should be made

in the floor surface to

bring the upper surface of

the temperature probe and

cable level with the

heating cable.

Conserve energy by

avoiding areas (such as

under water cistern) which

are not a normal area for

foot contact.

Heating Cable

Temperature Probe

Controller (must not be

mounted inside bathroom

150mm

=

Flexi-Fast Mat Layout

These give an output of between 133 and 200W/m

2

depending on the degree

of stretch (maximum stretch gives 133W/m

2

).

Initially decide on a location for the RCD and controller* then plan the run of

the cold cable to the start of the heating mat and the run of the temperature

probe flying lead remembering that no cable should run under or over any

other or the temperature probe which should be positioned as in figure 3.

The cold cable and probe flying lead (both 4m in length) may be shortened

as necessary.

Mats should run backwards and forwards between walls or obstructions.

Generally it will be sufficient to pin the mat at the start and finish of each

run if there is a degree of stretch in the mat. The techniques shown in figures

4 and 5 may prove useful. When cutting the mat webbing to give direction

changes or bypassing of obstacles take care not to cut or damage the heating

cable. Mat runs should be separated by at least 30mm and should not be run

under permanent fixtures. The cables within the mats should not get closer to

the tiling edge than 50mm and should clear permanent fixtures by the same

amount. If the longest flexi-fast mat in the range is not long enough to cover

the required area at the required W/m

2

a second flexi-fast mat or cable can be

used with the two cold cables connected to the controller – black to black to

controller live output and blue to blue to controller neutral output.

* These should not be located in a bathroom or near a sink or cooking facilities in a kitchen.

Obstacle cut

Corner cuts

Plain wall cut

Empty square

Filled square

Figure 5

When cutting the mat

webbing to give direction

changes or the bypassing

of obstacles take care not

to cut or damage the

heating cable.

=

Figure 1

82mm

Wood

floors

200W/m

2

160W/m

2

120W/m

2

62mm

50mm

Concrete/

screed floors