Sterlco BP800 Series Granulators User Manual

Page 32

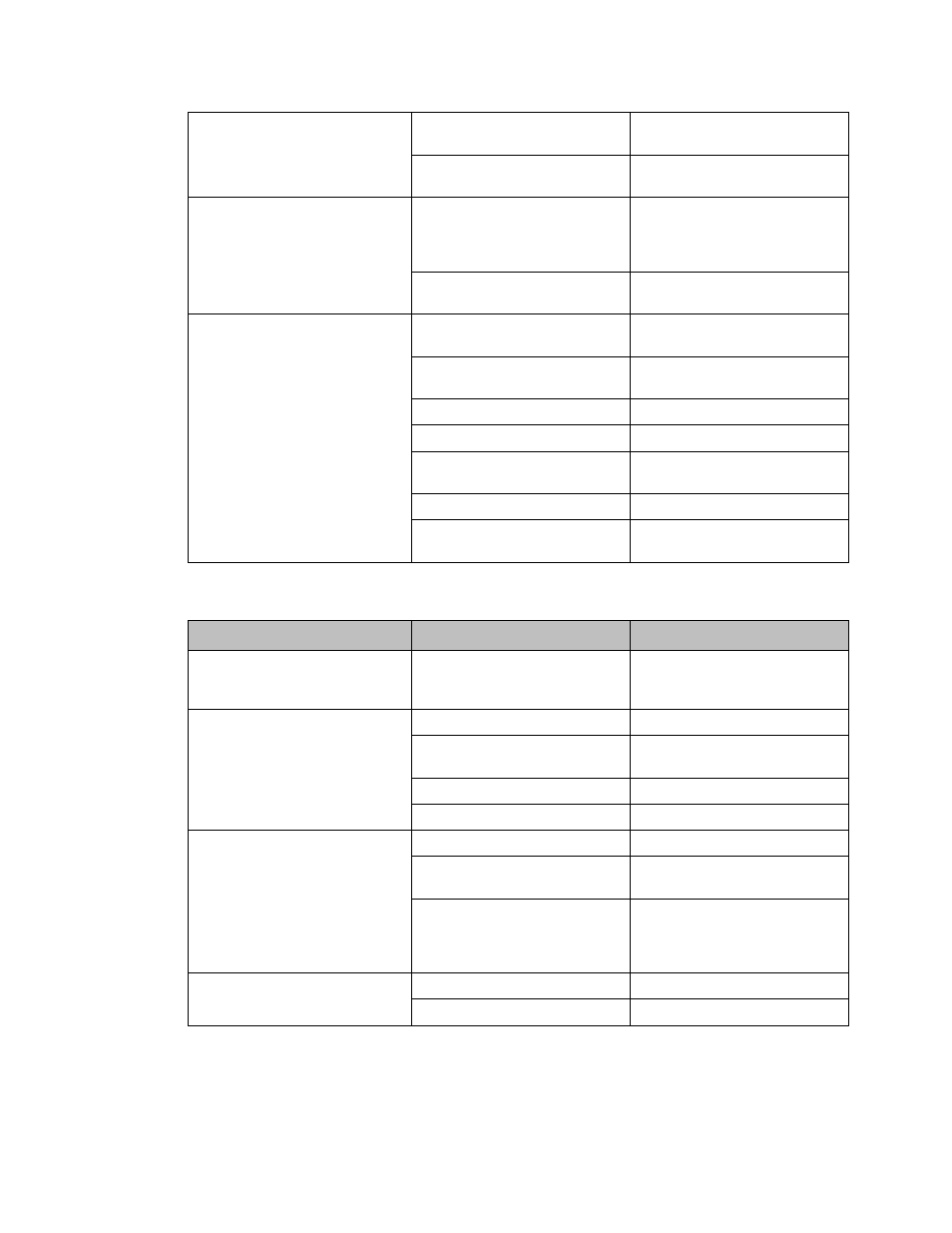

Chapter 6: Troubleshooting

32 of 41

Improper knife re-sharpening

Check dimensions with figures

included in this manual.

Abrasive material

Contact the supplier for special

knives

Abnormal screen wear

Incorrect fitting of screen

Check that the screen is

correctly seated in its rear

position and that it fits perfectly

at the front

Abrasive material

Contact the supplier for special

knives

Rotor jamming

Excessive in-feed material

Reduce amount of material

being fed to the machine

Total or partial obstruction of the

screen holes

Remove the screen and clear

the holes

Insufficient belt tension

Check and/or adjust belt tension

Knives worn

Replace with new knives

Distance between the knives too

small or large

Check distance between knives

Screen holes too small

Increase screen hole diameter

Failure of air conveying system

or discharge system

Check fan rotation and make

sure pipes are not obstructed

Electrical Problems

Problem

Possible Cause

Possible Remedy

Machine stops for no apparent

reason

Safety switch has stopped

power

Check that the knobs that

operate the safety switch are

tightened

Electric motor does not start

No power

Check fuses

Overload failure

Check amperage of electric

motor

Safety switch not working

Check and replace

Cutting chamber too full

Empty cutting chamber

Motor starts but does not speed

up or take a load

Excessive drive belt tension

Check belt tension and adjust

Motor connected to power

source incorrectly

Reconnect correctly

Defective starter winding

Check current in each phase. If

substantial difference between

phases, contact motor

manufacturer

Motor starts, but does not gain

speed

Bearing excessively worn

Replace bearings

Cutting chamber full

Empty cutting chamber