Chapter 6: troubleshooting, 1 introduction – Sterlco BP800 Series Granulators User Manual

Page 31

Chapter 6: Troubleshooting

31 of 41

Chapter 6: Troubleshooting

6-1 Introduction

The utmost in safety precautions should be observed at all times when working on or around

the machine and the electrical components. All normal trouble-shooting must be

accomplished with the power off, line fuses removed, and with the machine tagged as out of

service.

The use of good quality test equipment cannot be over-emphasized when troubleshooting is

indicated. Use a good ammeter that can measure at least twice the AC and DC current that

can be encountered for the machine. Be sure that the voltmeter has at least minimum

impedance of 5,000 OHMS-per-volt on AC and 20,000 OHMS-per-volt on DC scales.

Popular combination meters, VOM and VTVM can be selected to provide the necessary

functions.

Before making haphazard substitutions and repairs when defective electrical components are

malfunctioning, we recommend that you check the associated circuitry and assemblies for

other defective devices. It is common to replace the obviously damaged component without

actually locating the real cause of the trouble. Such hasty substitutions will only destroy the

new component. Refer to wiring diagrams and schematics.

Locating mechanical problems, should they occur, is relatively straightforward. When

necessary, refer to the parts catalog section.

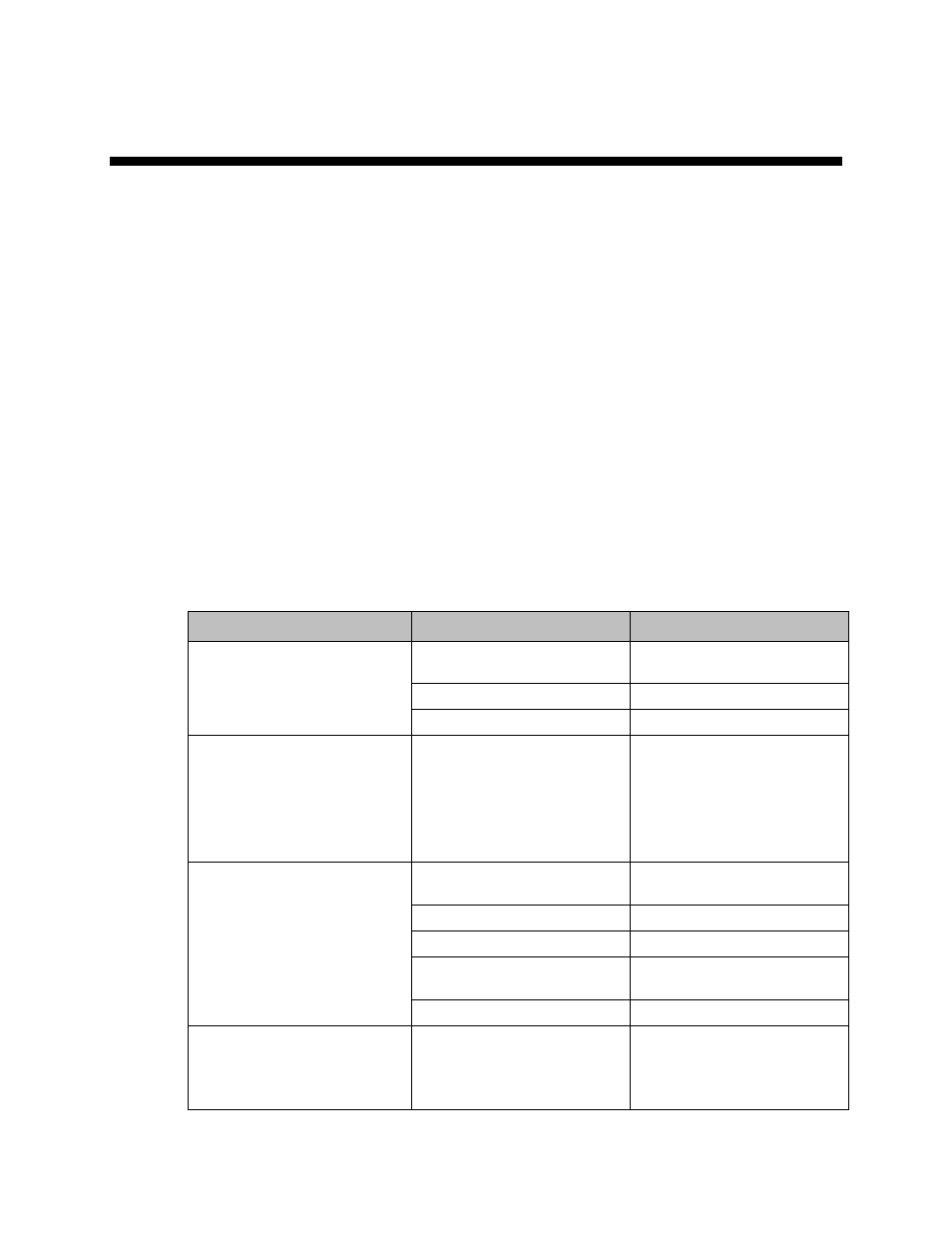

General Problems

Problem

Possible Cause

Possible Remedy

Overheating of bearings

Dirt or contamination in the

bearing

Correct source of contamination

Excessive belt tension

Adjust belt tension

No lubrication

Check bearing seals

Knives moving in their seats

May be foreign matter on the

knives

Carefully clean seat

Knife screws loose

Tighten screws with torque

wrench at values specified

Knife screws weakened

Screws must not be used more

than 6 times

Broken Knife

Improper re-sharpening

Check knife grinding method

used

Extremely hard material

Contact supplier

Incorrect rotor direction

Check rotor direction

Foreign body in the cutting

chamber

Look for cause with operator

Faulty fitting of screen

Check assembly procedure

Excessive knife wear

Incorrect knife position

Correct the gap or distance

between bed knives and rotor

knives