5 adjusting belt tension – Sterlco TG 1200 Series Thermoform Granulators User Manual

Page 23

T-Series Thermoforming Granulators Maintenance

23

of

37

5-5 Adjusting Belt Tension

For continuous reliable operation of the granulator, it is important that the belt tension is

correct. Correct tension reduces wear on rotor and motor bearings and keeps belt slip to a

minimum. Figure 7 gives the recommended force to deflect each belt by an amount equal to

the belt span divided by 64. A gauge is available through the sales department to measure the

deflection and force. Use the following procedure to adjust the belt tension:

Tension new belts at the maximum run-in force, and check the tension at least two times

during the first two days of operation. There is normally a rapid decrease in the tension until

the belts are run in.

Note: The deflection force value shown must be multiplied by the number of V-belt

elements.

1. Turn off the granulator at the main isolator switch and remove fuses.

2. Remove the belt guard to gain access to the belts.

3. Determine the type of belt required from the Spare Parts List on page 34.

4. Determine the force required to deflect one belt 1/64” (0.40 mm) per 1 inch (25.4

mm) of span length.

5. Loosen the motor base slide mount screws and turn the adjusting screw on the base to

tension the belts as required (See Figure 7).

6. Re-tighten the screws, making sure the sheaves are in correct alignment.

7. Replace the covers.

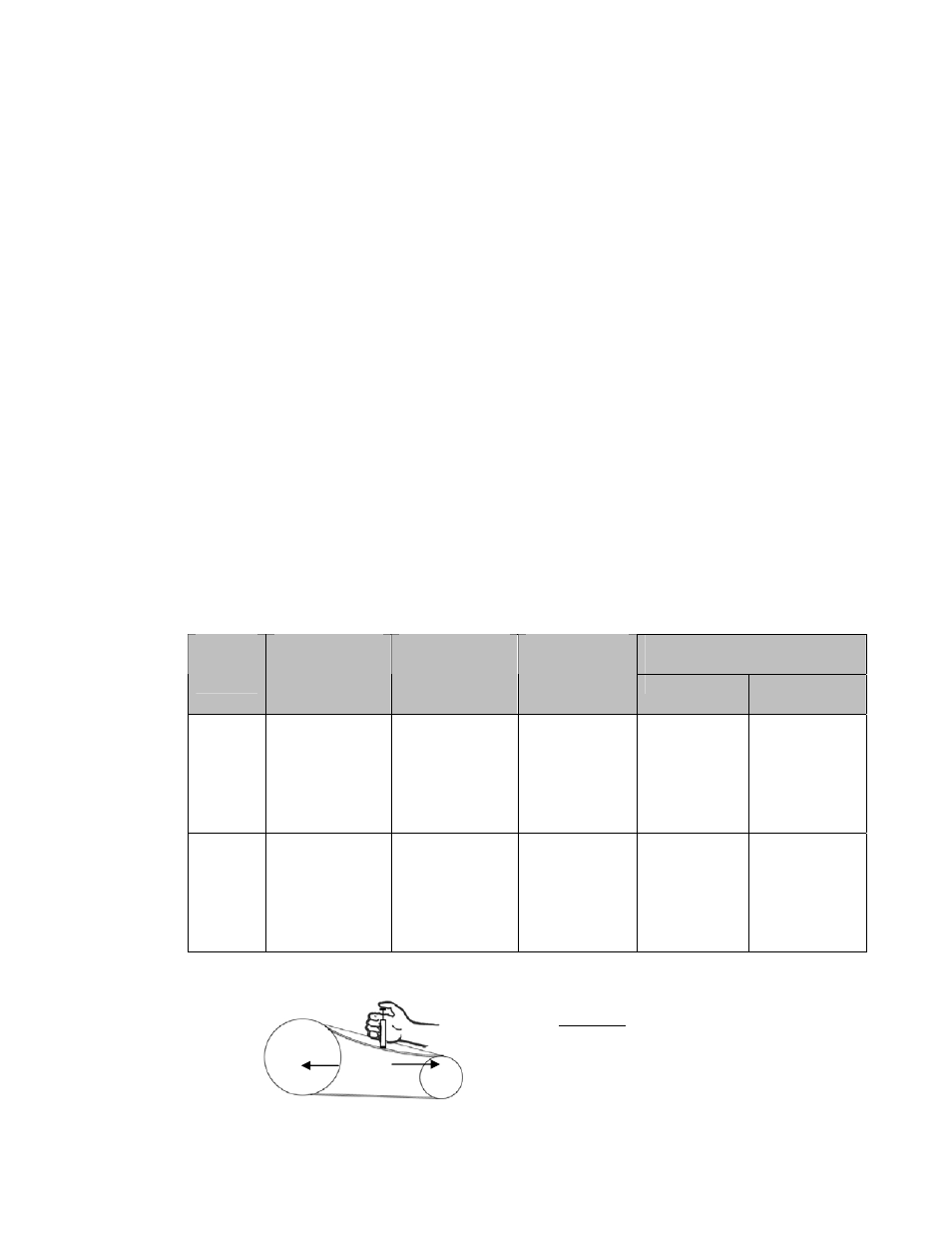

Figure 7: Belt Tensioning Information

Recommended Deflection

Force (Lbs.)

V-Belt

Cross

Section

Small Sheave

Diameter

Range

(Inches)

Small Sheave

RPM Range

Speed Ratio

Range

Run-In

Normal

Running

B 3.4

4.6

5.0-5.2

5.4-5.6

6.0-6.8

7.4-9.4

1160 to 1800

2.0 to 4.0

5.4

7.4

8.5

9.1

10.0

12.0

3.8

5.1

5.8

6.2

7.1

8.1

BX 3.4

4.6

5.0-5.2

5.4-5.6

6.0-6.8

7.4-7.9

1160 to 1800

2.0 to 4.0

7.4

10.0

11.0

11.0

11.0

12.0

5.2

7.1

7.3

7.4

7.7

7.9

*This deflection force value relates to a single V-belt element. Therefore, if the belt is a 3-V

element (3V-banded), this value must be multiplied by 3.

Deflection = Belt Span

64

Belt Span=37”