Chapter 5: maintenance – Sterlco TG 1200 Series Thermoform Granulators User Manual

Page 18

T-Series Thermoforming Granulators Maintenance

18

of

37

Chapter 5: Maintenance

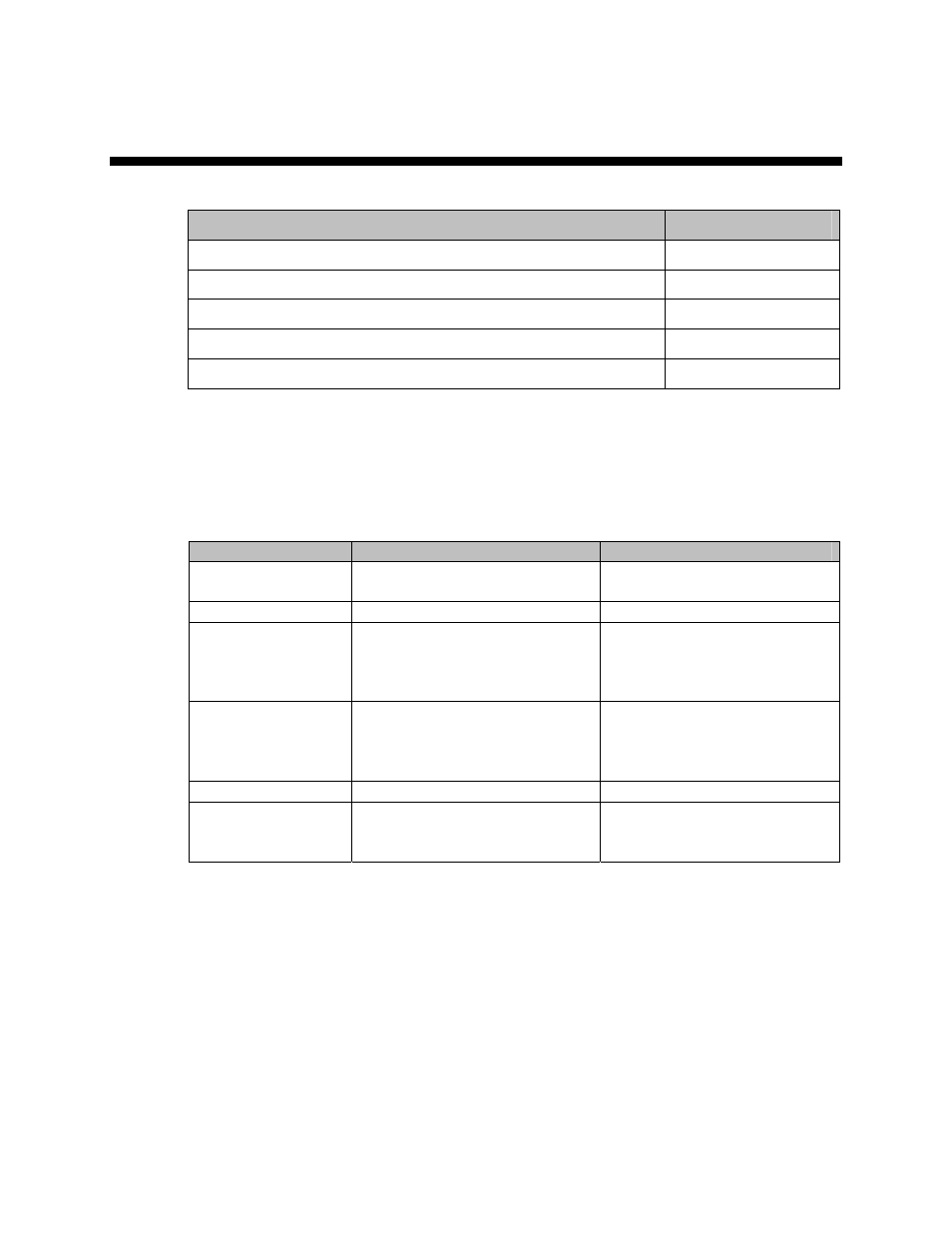

5-1 Preventative Maintenance Schedule

Check

Frequency

Operation of safety interlock switches

Daily

Knife clearance (0.15 mm – 0.20 mm; 0.006” – 0.008”)

Weekly

Knife retaining screws for tightness (271 Nm; 200 lbs./ft.)

Weekly

Knife exposure (1.0 mm; 0.040”)

Weekly

Belt tension

Monthly

5-2 Lubrication

The main drive motor, rotor bearings, feed roll reductor, tension idler sprocket, feed roll

cartridge bearings, and feed roll drive chain are all pre-lubricated at the factory. Check and

re-lubricate according to Figure 3.

Figure 3: Lubrication Requirements

Lubrication Point

Lubricant

Frequency

Drive motor

Refer to instruction plate on

motor

4 months or 3000 hours

Feed roll reductor

#90 Lube oil

Refill as needed

Feed roll cartridge

bearings

Chevron SRI #2

Exxon Andok C

Lidok EP1

2 months or 1500 hours. Grease

when machine is stopped until

small bead appears at bearing

seal, then wipe clean.

Feed roll tension arm

idler sprocket

Chevron SRI #2

Exxon Andok C

Lidok EP1

2 Months or 1500 hours. Grease

when machine is stopped until

small bead appears at nut edge,

then wipe clean.

Feed roll drive chain

Molykote Lubricant

As required by visual inspection

Rotor bearings

Chevron SRI #2

Exxon Andok C

Lidok EP1

2 Months or 1500 hours at 1

oz./bearing.