Installation — electrical, Warning – Ouellet OHX User Manual

Page 6

6

— INSTALLATION —

Electrical

1. Heater is to be connected and serviced only by qualified electrician experienced with hazardous location equipment. It is the responsi-

bility of the installer to verify the safety and suitability of the installation.

2. Explosion/Electric Shock Hazard. Disconnect heater from power supply or fuse box before opening enclosures or servicing heater.

Lock the switch in the “OFF” (open) position and/or tag the switch to prevent unexpected power application.

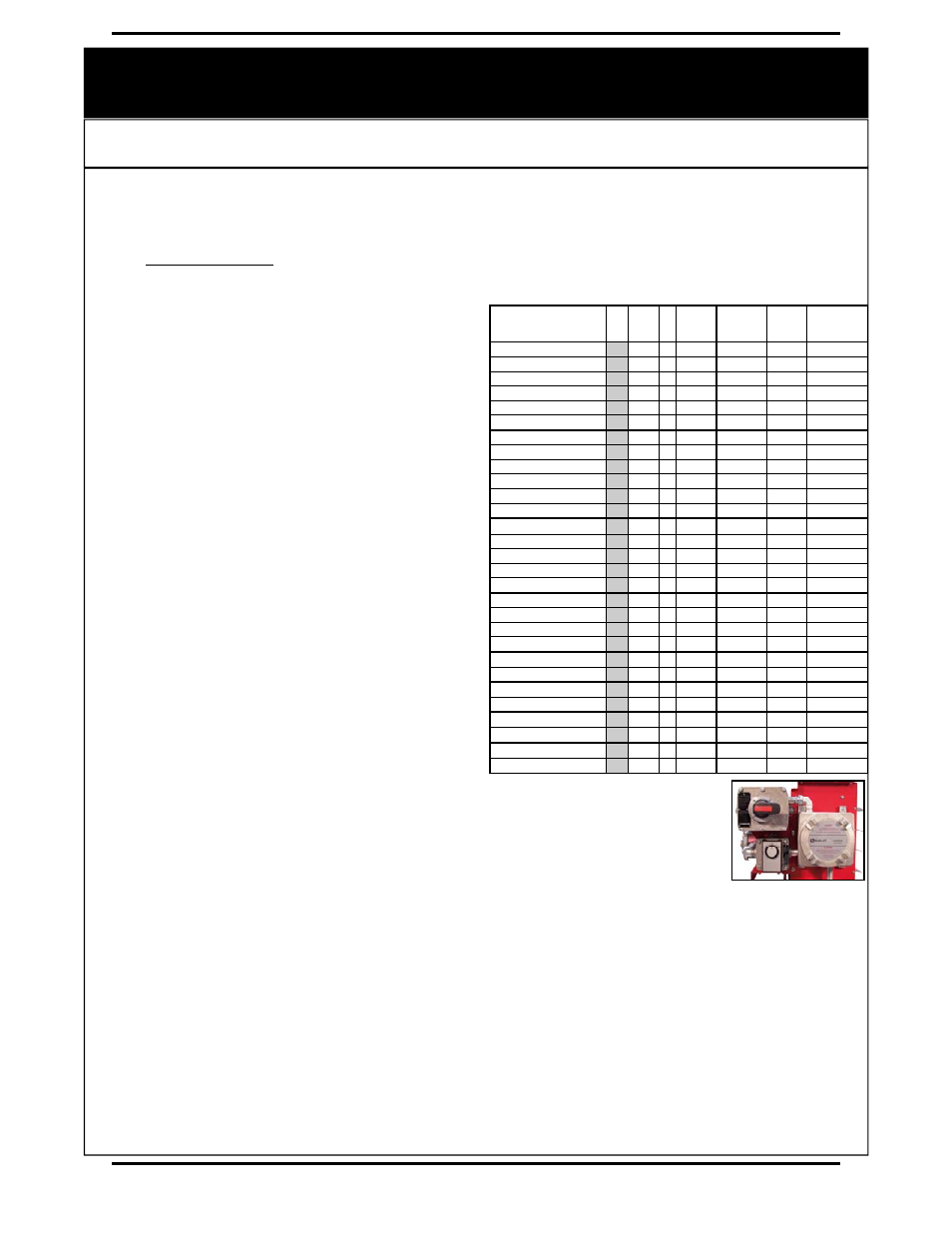

3. Use copper conductors only for supply wires and approved explosion-proof means of wiring during installation. Use minimum 90°C

rated wire. Refer to “Supply Wire Requirements” table and heater data plate for conductor wire rating.

4. Installation must include appropriate over-current protection de-

vices (fusing or circuit breakers) as required by the CEC or NEC.

Refer to “Supply Wire Requirements” table and heater data plate

for current ratings. Supply voltage is to be within 10% of the data

plate voltage.

5. Confirm that the electrical power supply matches the nameplate

voltage, phase, amperage and frequency rating of the heater to be

connected.

6. Supply conductors and ground conductor pass through the 1 in.

NPT rigid conduit opening on the control enclosure.

7. Proper installation of the heater requires that an adequate ground-

ing conductor be connected to the ground terminal. This terminal

is made of copper and is located on the top right-hand corner of

the printed circuit board within the control enclosure.

8. Heater may be supplied with a factory installed integral room ther-

mostat (See Figure 1). On heaters not supplied with this option, it

is recommended that an external explosion-proof room ther-

mostat be used. The wiring to the external thermostat must be

copper wire, 16 gauge minimum (for Class II) or 14 gauge mini-

mum (for Class I). Thermostat conductors may also be passed

through the 1 in. NPT conduit opening or through the convenient

3/4 in. NPT dedicated external thermostat conduit opening in the

enclosure. Connect the external thermostat conductors to the

printed circuit board terminal block marked “T’STAT”. The built-in

control transformer supplies the heater with either 120V or 24V for

internal unit operation. This voltage will appear across the thermo-

stat contacts when they are open. The minimum thermostat con-

tact rating should be 1 amp @ 120 VAC. Refer to nameplate for

control voltage of unit.

9. Refer to wiring diagram on Page 9 to ensure that all connections

are as required and securely fastened.

10. For heaters supplied with a factory installed integral disconnect switch (See Figure 1), field wiring is as fol-

lows:

a. Remove the Disconnect cover assembly from the base by removing the six (6) cover bolts. Set the cover

assembly aside. CAUTION: Damaging the mating surfaces of the enclosure could destroy the flame path

and jeopardize the integrity of the flame proof enclosure.

b. Supply conductors and ground conductor pass through the 1 in. NPT rigid conduit opening located on the

top or bottom of Disconnect Enclosure. Supply conductors to be wired to DIN rail mounted Disconnect

Switch inside. Ground conductor to be wired to Ground Lug fastened to inside of Disconnect Enclosure.

Refer to wiring diagram on Page 9.

c. Attach cover to the enclosure using the six (6) bolts. Tighten to 150 inch-pounds ± 5 in-lbs.

11. All unused threaded openings in enclosures, not used for supply wiring or external room thermostat, must be fitted with threaded plugs

approved for use in hazardous locations (included). Factory installed conduits require no additional sealing.

12. Installer must seal each conduit run within 18” (457 mm) of enclosure. This seal must be suitable and listed for hazardous locations.

13. Ensure that input conductors and conduit have adequate strain relief at installation.

14. Before application of electrical power, recheck all connections to ensure compliance with the wiring diagram and any code require-

ments. Remove any foreign objects from the control box and heater. Reinstall cover tightly.

15. On all three-phase heaters, it is necessary to verify that the fan rotation is correct (counter clockwise when facing the rear of the

heater). If air delivery is not from the front of the heater, reverse any two supply leads at the main power contactor located in the

control enclosure.

16. The explosion-proof control enclosure and element enclosures are designed with O-rings, threaded joints and metal-to-metal contact at

the lid or cover joint to prevent an explosion. Do not attempt to install gasket material of any type at these joints. A light coating of anti-

seize compound may be applied to the threads to prevent seizing.

— WARNING! —

Read and follow the instructions in this manual. Failure to do so may result in severe or fatal injury.

Model

kW Volts Ø

Total

Current

Amps

Minimum

Circuit

Ampacity

Max F

use

Amps

Supply

Wire

90°C (AWG)

OHX05008-

5 208 1 26.5 33.2

35

8

OHX05000-

5 240 1 23.3 29.2

30

10

OHX05038-

5 208 3 14.6 18.2

20

12

OHX05030-

5 240 3 12.7 15.9

20

12

OHX05034-

5 480 3 6.7

8.4

15

14

OHX05036-

5 600 3 5.5

6.9

15

14

OHX07508-

7.5 208 1 38.6

48.2

50

6

OHX07500-

7.5 240 1 33.8

42.2

50

8

OHX07538-

7.5 208 3 21.5

26.9

30

10

OHX07530-

7.5 240 3 18.7

23.4

30

10

OHX07534-

7.5 480 3 9.7

12.2

15

14

OHX07536-

7.5 600 3 7.9

9.9

15

14

OHX10000-

10 240 1 44.2

55.2

60

6

OHX10038-

10 208 3 28.5

35.6

40

8

OHX10030-

10 240 3 24.8

30.9

35

8

OHX10034-

10 480 3 12.7

15.9

20

12

OHX10036-

10 600 3 10.3

12.9

15

14

OHX15038-

15 208 3 42.3

52.9

60

6

OHX15030-

15 240 3 36.8

46.0

50

6

OHX15034-

15 480 3 18.7

23.4

25

10

OHX15036-

15 600 3 15.1

18.9

20

12

OHX20034-

20 480 3 24.8

30.9

35

8

OHX20036-

20 600 3 19.9

24.9

25

10

OHX25034-

25 480 3 31.1

38.8

40

8

OHX25036-

25 600 3 25.1

31.3

35

8

OHX30034-

30 480 3 37.1

46.4

50

6

OHX30036-

30 600 3 29.9

37.3

40

8

OHX35034-

35 480 3 43.1

53.9

60

6

OHX35036-

35 600 3 34.7

43.3

50

6

OHX Supply Wire Requirements

Figure 1