Dwyer instruments, inc – Dwyer A-1000 User Manual

Page 2

©Copyright 2010 Dwyer Instruments, Inc.

Printed in U.S.A. 8/10 FR# R1-443417-00 Rev. 1

Tube O.D.

[Size (in)]

1/16

1/8

3/16

1/4

5/16

3/8

1/2

5/8

3/4

7/8

1

1-1/4

1-1/2

2

.010

5600

.012

6850

.014

8150

.016

9500

.020

12100

.028

8550

5450

4000

.035

11000

7000

5100

4050

3300

2450

.049

10300

7500

5850

4800

3500

2950

2400

2050

.065

10300

8050

6550

4750

4000

3300

2800

2400

.083

6250

5200

4250

3600

3150

2450

.095

6050

4950

4200

3650

2850

2350

.109

5800

4850

4200

3300

2700

2000

.120

4700

3650

3000

2200

.134

4150

3400

2500

.156

4900

4000

2900

.188

4900

3600

Wall Thickness of Tube (Inches)

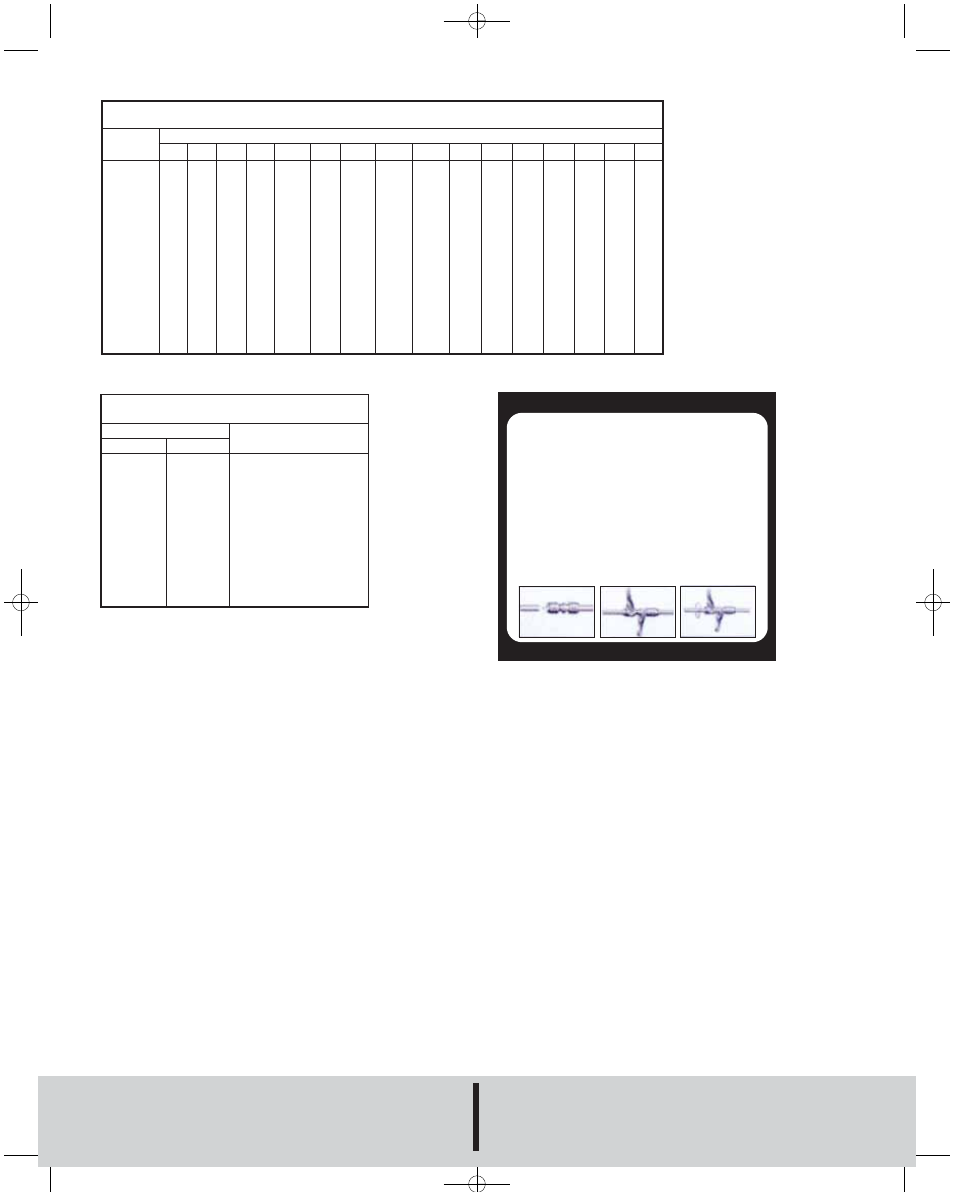

STAINLESS STEEL TUBING - TABLE A

Maximum Allowable Working Pressure (PSIG)

°F

100

200

300

400

500

600

700

800

900

1000

1200

Temperature

Stress Factors For Determining Tubing Pressure

Ratings at Elevated Temperatures - TABLE B

°C

38

93

149

200

260

316

371

427

482

538

649

Stainless Steel

316

1.00

1.00

1.00

.97

.90

.85

.82

.80*

.78*

.73*

.37*

DWYER INSTRUMENTS, INC.

Phone: 219/879-8000

www.dwyer-inst.com

P.O. Box 373 • Michigan City, IN 46361-0373, U.S.A.

Fax: 219/872-9057

e-mail: [email protected]

* The precipitation of chromium carbides potentially

resulting in intergranular corrosion may occur when

exposed to operating temperatures.

Dwyer

®

Tube Fittings

MADE IN USA

INSTALLATION INSTRUCTIONS

1. Dwyer

®

tube fittings come individually bagged and com-

pletely assembled for immediate use. There is no need for dis-

assembly prior to use. Simply remove the tube fitting from its

bag, insert the tube until it bottoms in the Dwyer

®

tube fitting

body and then hand tighten the Dwyer

®

nut. See Figure #1.

2. While holding the fitting body stable with a back up wrench

scribe the nut for a reference point and wrench tighten the nut

1-1/4 turns for sizes 1/4˝ - 1˝ and 3/4 turn for sizes 1/16˝ - 3/16˝.

See figures #2 and #3.

[Note: For all sizes, tighten plugs (P), machined ferrule and at

port connector (PC) and the Dwyer end of the AN adapter

(ANF) only 1/4 of a turn.]

2

3

1

A-1000:A-1000 8/24/10 10:11 AM Page 2