W.e. anderson div., dwyer instruments, inc – Dwyer ABFV User Manual

Page 4

©Copyright 2006 Dwyer Instruments, Inc.

Printed in U.S.A. 12/06

FR# R2-443533-00

Page 4

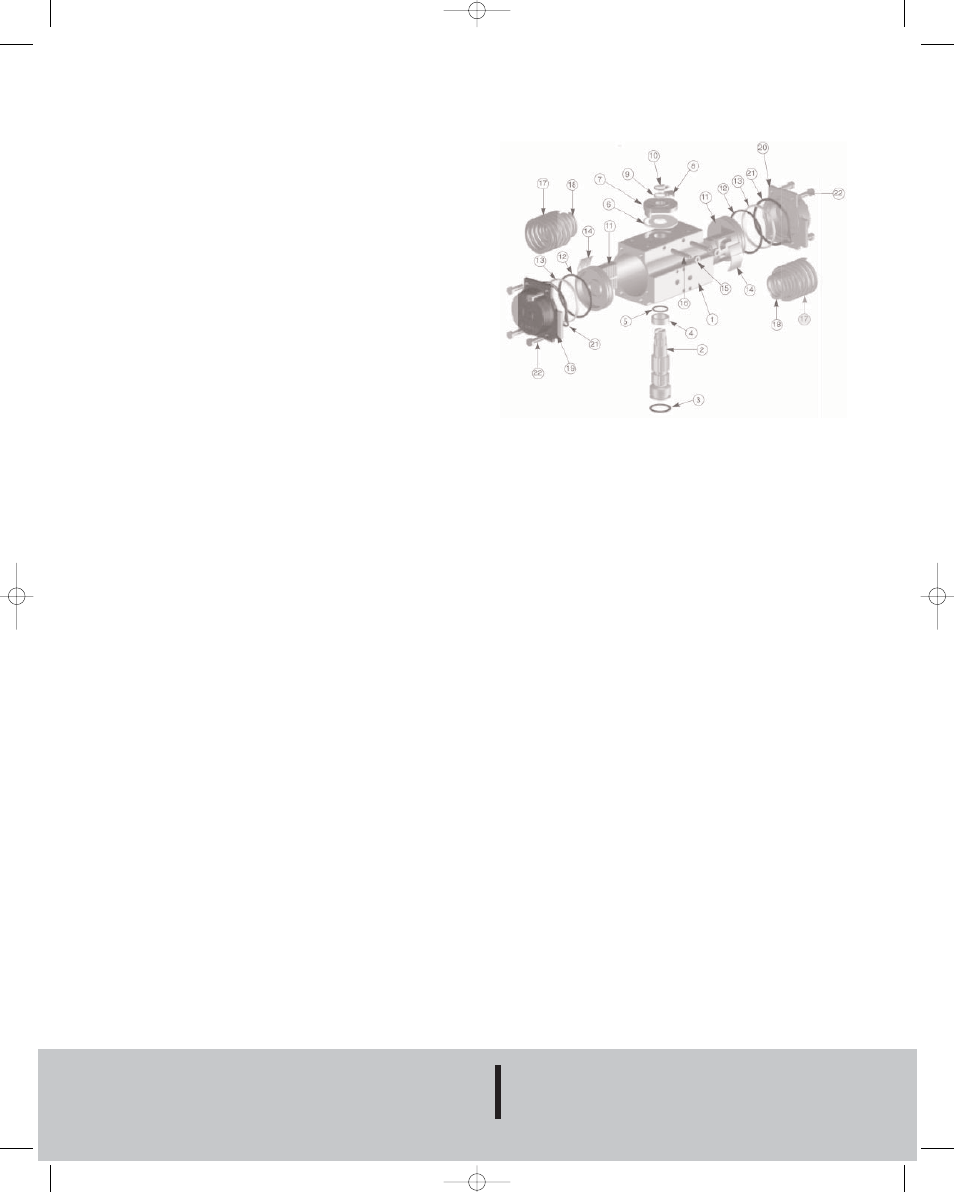

PNEUMATIC ACTUATOR PARTS LIST

1. Extruded aluminum housing

2. Nickel plated steel anti-blowout pinion

3. NBR 70 lower pinion O-ring

◊

4. PTFE pinion spacer ring

◊

5. NBR 70 top pinion O-ring

◊

6. PTFE cam spacer ring

◊

7. SS indicator cam

8. Nylon position indicator

9. SS pinion washer

10. Pinion snap ring

11. Die cast aluminum piston

12. Piston O-ring bushing

◊

13. PTFE antifriction ring

◊

14. PTFE piston thrust block

◊

15. SS stop bolt retaining nut

16. SS stop bolt

17. External spring*

18. Internal spring*

19. Die cast aluminum end cap (left)

20. Die cast aluminum end cap (right)

21. NBR end cap seats

22. SS end cap bolt

*spring return actuators only parts subject to wear. Please contact the

factory or your W.E. Anderson distributor for replacement kits.

MAINTENANCE

The Series ABFV Automated Butterfly Valves are not field

serviceable and should be returned if repair is needed (field repair

should not be attempted and may void warranty). Be sure to

include a brief description of the problem plus any relevant

application notes. Contact customer service to receive a return

goods authorization number before shipping.

PNEUMATIC ACTUATOR

NOTE: For optimal operation, 3PBV actuators should be run with a

supply of clean, lubricated air.

SPRING RETURN ACTUATORS

Air to PORT 2 (the right hand port) causes the actuator to turn CCW.

Loss of air to PORT 2 causes air to exhaust and the actuator turns

CW. This is the FAIL CLOSE operation.

DOUBLE ACTING ACTUATORS

Air to PORT 2 (the right hand port) causes the actuator to turn CCW.

Air to PORT 1 (the left hand port) causes the actuator to turn CW.

DISASSEMBLING STANDARD ACTUATORS

IMPORTANT: Before beginning disassembly, ensure that the air

supply to the actuator has been disconnected, all accessories have

been removed and that the actuator has been dismounted from the

valve.

1. Loosen the end cap fasteners (22) with a wrench (size varies

depending on actuator model). On the spring return actuator, alternate

3 to 5 turns on each fastener until the springs are completely

decompressed. Use caution in removing the cap since the springs are

under load until the fasteners are fully extended.

2. Remove the pinion snap ring (10) with a lock ring tool. The indicator

(7) may now be removed.

3. Turn the pinion shaft (2) CCW until the pistons are at the full end of

travel. Disengage the pistons (11) from the pinion. (NOTE: Low

pressure air--3 to 5 P.S.I. MAXIMUM--might be required to force the

pistons completely from the body.) Note the position of the pistons

before removing them from the actuator body. The part numbers of the

pistons are located on the side and should be right-side up on an

actuator with a standard orientation.

4. Remove the pinion through the bottom of the actuator. The actuator

is now completely disassembled. All replacement parts may now be

put in. W.E. Anderson recommends that all wear parts (3, 4, 5, 6, 12,

13, 14) be replaced before reassembly.

REASSEMBLING STANDARD ACTUATORS

IMPORTANT: Be sure that the actuator surfaces are free of grit

and scratches before reassembling.

1. Apply a light film of grease to all o-rings and the pinion before

replacing.

2. Put the pinion (2) back through the actuator with the flats of the

pinion shaft running parallel with the body.

3. When reassembling the actuator, make sure that the piston racks

are square to the actuator body and returned to their original

orientation. (NOTE: The normal operation of all PBV pneumatic

actuators is FAIL CLOSED. To change the orientation to FAIL OPEN,

rotate the racks 180º to create a reverse operation.)

4. When replacing springs in a spring return actuator, ensure that the

springs are replaced in their identical position in the end cap from

which they were removed. (NOTE: In some circumstances, you might

want to change the standard 80 pound spring set to fit your

application and available air pressure. Changing the spring sets on

3PBV pneumatic actuators requires no special tools. Please refer to

the spring combination torque chart in our catalog for the inner and

outer spring combinations that will allow you to operate with the spring

set that you desire.)

4. Seal the end caps with a petroleum lubricant and bolt to actuator

body.

5. Check the seal of the actuator by covering seal areas (pinion, end

caps) with soapy water and using low pressure air to the actuator to

ensure that no bubbles are produced.

PNEUMATIC ACTUATOR

W.E. ANDERSON DIV., DWYER INSTRUMENTS, INC.

P.O. BOX 358 • MICHIGAN CITY, INDIANA 46361 U.S.A.

Phone: 219/879-8000

www.dwyer-inst.com

Fax: 219/872-9057

e-mail: [email protected]

V-28 12/18/06 10:03 AM Page 4