Proximity controls – Dwyer MPR User Manual

Page 2

PROXIMITY CONTROLS

Phone: 219/879-8000

www.dwyer-inst.com

A DIVISION OF DWYER INSTRUMENTS, INC.

Fax: 219/872-9057

e-mail: [email protected]

P.O. BOX 373 • MICHIGAN CITY, INDIANA 46360, U.S.A.

©Copyright2013 DwyerInstruments,Inc.

PrintedinU.S.A.8/13FR-#RB-443190-00Rev.4

3. CLEANING: Cleanpartsinwarmwaterandmildsoapandletairdry.

Usingdry,cleancompressedair,blowoutthebody.Ifanypartsare

damaged,consultthefactoryforanRGA (ReturnedGoods

Authorization) number.

4. TO REASSEMBLE:LubricateO-ringonsupplyseatwithquality

O-ringgrease.Tightensupplyseatintobodyofregulator.Makesure

thepintleslidesupanddownfreelyaftertighteningsupplyseat.

Tightenbonnetontobody.Do not over tighten, as it could strip

bonnet threads.

WARNING

1.TheSeriesMPRMiniaturePressureRegulatorsareintendedforuse

inindustrialcompressedairsystemsonly.Donotusewhere

pressureandtemperaturescanexceedthoselistedunder

SPECIFICATIONS inthismanual.

2.Inrelieving-typeregulators(MPR1),excesspressureisventedoutof

theregulatorwhenthereisanincreaseindownstreampressure

abovethepressuresetting.However,reliefcapacityislimited.Ifa

suddenincreaseindownstreampressurecouldruptureor

malfunctiondownstreamequipment,installapressure-reliefdevice

downstreamoftheregulator.Thecapacityofthereliefdevicemust

satisfythesystemrequirements.

3. Innon-relievingregulators(MPR2),downstreampressureabovethe

pressuresettingdoesnotrelievetoatmosphere.Anothermeansof

relievingpressuremustbeprovided,ifnecessary.

4. Beforeusingtheseproductswithanythingotherthanairorthe

specifiedfluids,fornon-industrialapplications,life-supportsystems,

orotherapplicationsnotwithinpublishedspecifications,please

consultthefactory.

MAINTENANCE

UponfinalinstallationoftheSeriesMPRMiniaturePressureRegulator,

no routine maintenance is required. A periodic check of the system

calibrationisrecommended.TheSeriesMPRisnotfieldserviceableand

should not be returned if repair is needed (field repair should not be

attemptedandmayvoidwarranty).Besuretoincludeabriefdescription

of the problem plus any relevant application notes. Contact customer

servicetoreceiveareturngoodsauthorizationnumberbeforeshipping.

MAINTENANCE

WARNING: Air supply pressure must be shut off before attempting

to install or disassemble regulator for servicing.

1. Ifairsupplyiskeptclean,regulatorshouldprovidelong periodsof

uninterruptedservice.Iferraticperformanceoccurs,itislikelythat

partsintheregulatorneedtobecleanedorreplaced.

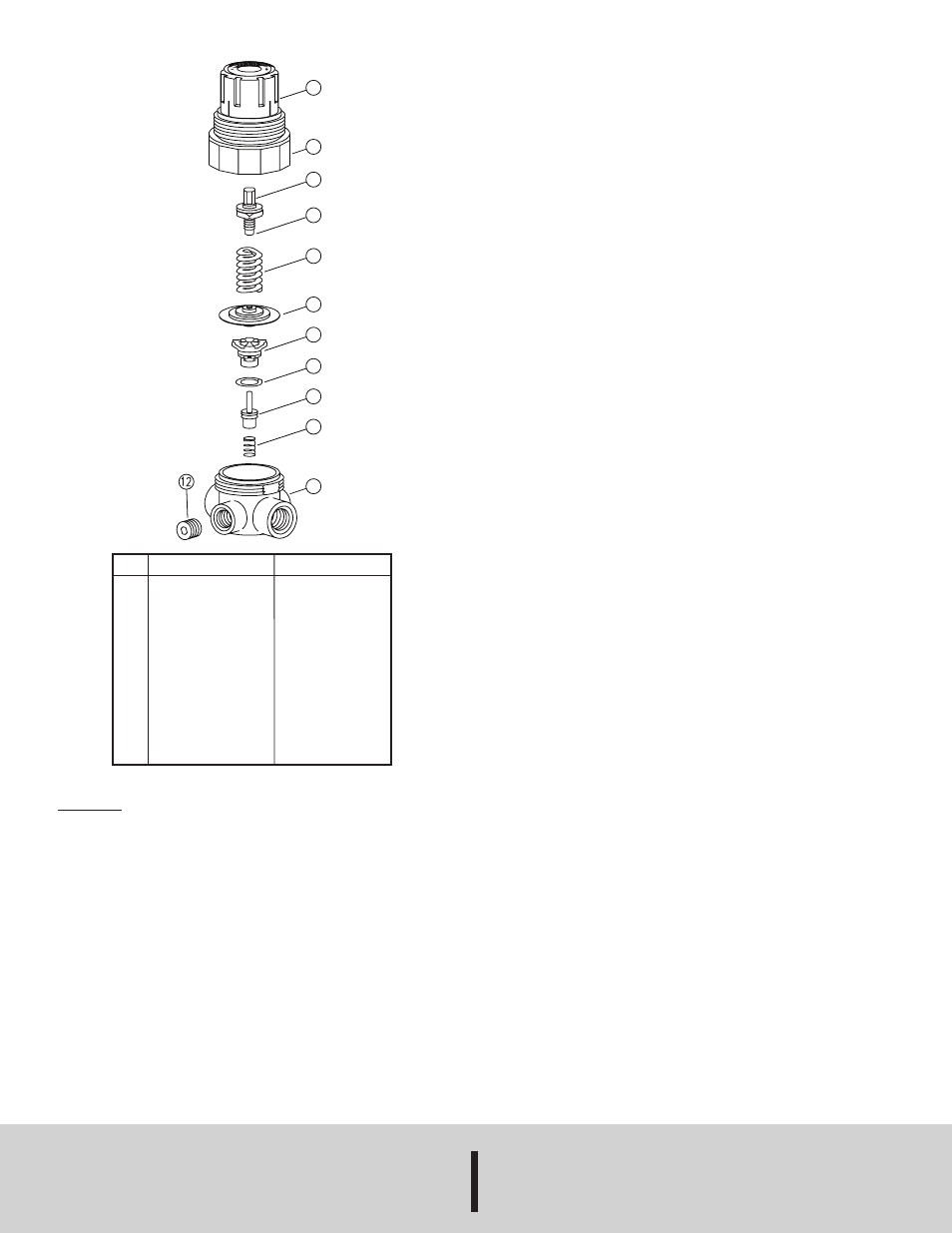

2. TO DISASSEMBLE: Reduce pressure in inlet and outlet lines to

zero. Regulator can be serviced without removal from line.

Pullknobouttodisengagelockandturnknobcounter-clockwise

untilitstops.Thiswillremoveanyloadontherangespring.

Unscrewbonnet.Adjustingscrewandnutarenotretained,and

mayfallout.Removerangespringanddiaphragmassembly.

Unscrewsupplyseat(hexsocketsizeis9/16˝),andremovepintle

andpintlespring.

1

2

3

4

5

6

7

8

9

10

11

No.

1

2

3

4

5

6

7

8

9

10

11

12

Part Description

Knob

Bonnet

AdjustingScrew

AdjustingNut

RangeSpring

DiaphragmAssembly

SupplySeat

SupplySeatO-Ring

Pintle

PintleSpring

Body

PipePlugs

Material

Acetal

Acetal

Zinc-PlatedSteel

Zinc-PlatedSteel

Zinc-PlatedSteel

Acetal/Nitrile

Acetal

Nitrile

Aluminum/Nitrile

300StainlessSteel

ZincAlloy

Steel