W.e. anderson div., dwyer instruments, inc – Dwyer TDST User Manual

Page 2

W.E. ANDERSON DIV., DWYER INSTRUMENTS, INC.

P.O. BOX 358 • MICHIGAN CITY, INDIANA 46360 U.S.A.

Phone: 219/879-8000

www.dwyer-inst.com

Fax: 219/872-9057

e-mail: [email protected]

©Copyright 2014 Dwyer Instruments, Inc.

Printed in U.S.A. 3/14

FR# RV-443580-00 Rev. 2

NPT

Connection

3/8˝

1/2˝

3/4˝

1˝

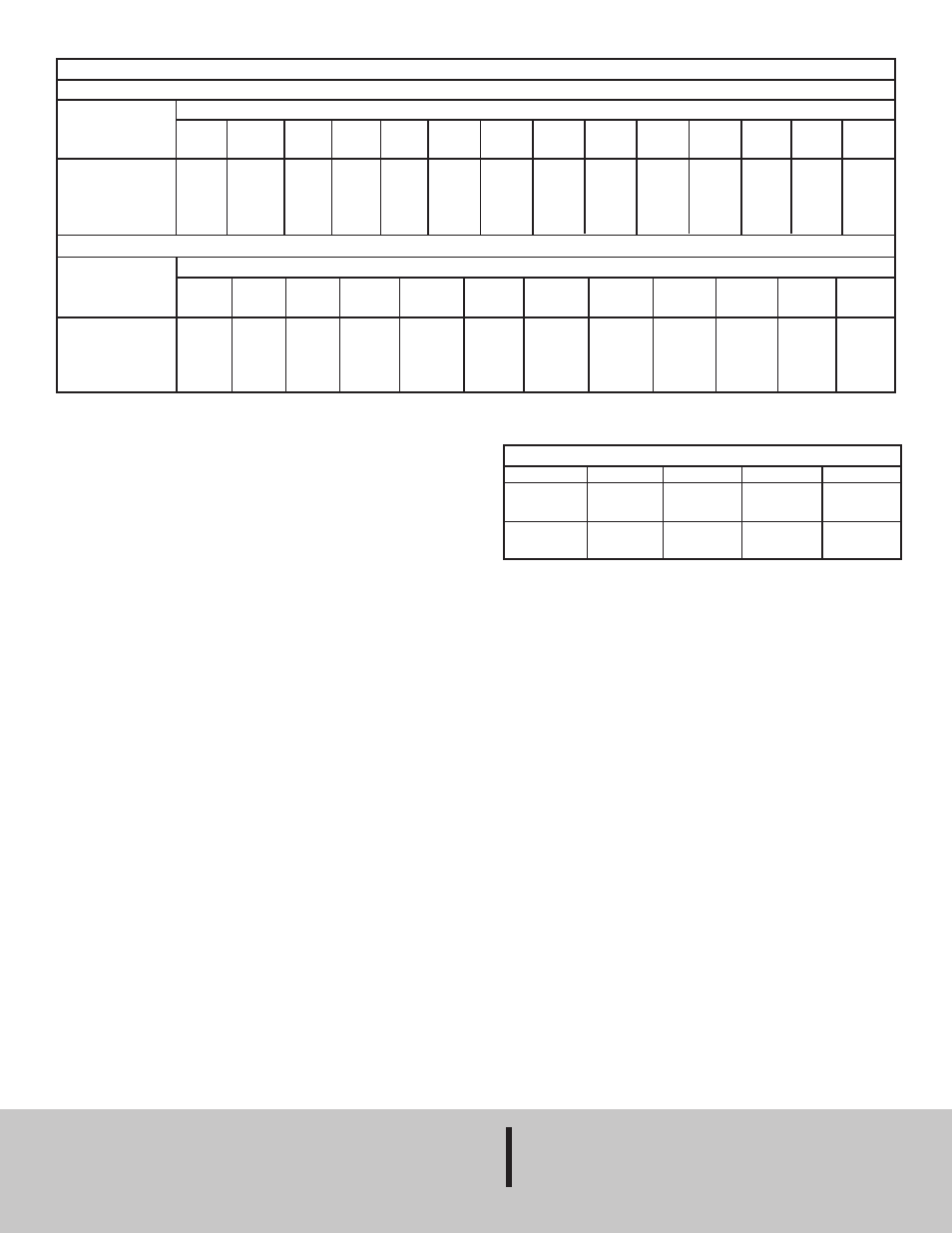

Capacity Chart

TDST-SSSD Maximum Capacity - lbs/hr 10°F Below Saturation

Differential Pressure psig (bar)

3.5

(0.24)

180

300

405

640

5

(0.34)

185

310

420

670

10

(0.7)

190

345

470

725

20

(1.4)

200

410

560

865

30

(2.1)

215

465

640

980

50

(3.4)

245

575

810

120

75

(5.2)

305

700

1000

147

100

(6.9)

370

810

1160

175

150

(10.3)

500

1000

1450

2200

200

(13.8)

610

1140

1670

2600

300

(20.7)

790

1410

2100

3250

400

(27.6)

960

1630

2430

3780

500

(34.5)

1100

1830

2750

4250

600

(41.3)

1250

2000

3050

4700

TDST-SSST Maximum Capacity - lbs/hr 10°F Below Saturation

NPT

Connection

3/8˝

1/2˝

3/4˝

1˝

10

(0.7)

315

315

650

650

20

(1.4)

370

370

740

740

30

(2.1)

425

425

800

800

50

(3.4)

520

520

1000

1000

75

(5.2)

575

575

1100

1100

100

(6.9)

800

800

1400

1400

150

(10.3)

900

900

1540

1540

200

(13.8)

1080

1080

1630

1630

300

(20.7)

1280

1280

1760

1760

400

(27.6)

1380

1380

1930

1930

500

(34.5)

1480

1480

2070

2070

600

(41.4)

1650

1650

2200

2200

Differential Pressure psig (bar)

3/8˝

65-75

(88-102)

105-115

(142-156)

Trap Size

TDST-

SSSD

TDST-SSST

1/2˝

85-95

(115-129)

105-115

(142-156)

3/4˝

105-115

(142-156)

105-115

(142-156)

1˝

120-130

(163-176)

105-115

(142-156)

Torque Values for Cover ft-lb (N-m)

MAINTENANCE

When using the SSSD models it is strongly recommended

to blow-off accumulation in the strainer a day or two after

the system has been installed. A periodic blow-off or

cleaning of the strainer should be instituted.

If trap fails, close isolation valves and remove cap using a

suitable spanner. Dirt or sediment on the disc or body

seating will cause abnormal operation. To clean these

parts use a soft cloth and solvent. DO NOT WIRE BRUSH

OR USE ANY ROUGH IMPLEMENT. Reassemble the

unit with the groove in the disc facing down. Apply

antiseize compound on the cap threads. Avoid getting

compound on the disc or body seating surfaces. See the

torque table to the right for recommended torque values.

For the SSST option a peroidic cleaning of the strainer

should be instituted. Unscrew the strainer plug using a

suitable spanner, withdraw the screen and clean it or

replace it if damaged. To reassemble, reverse the

procedure. A periodic check of system calibration is

recommended. The Series TDST is not field serviceable

and should be returned if repair is needed (field repair

should not be attempted and may void warranty). Be sure

to include a brief description of the problem plus any

relevant application notes. Contact customer service to

receive a return goods authorization number before

shipping.