Dwyer instruments, inc – Dwyer DDC User Manual

Page 2

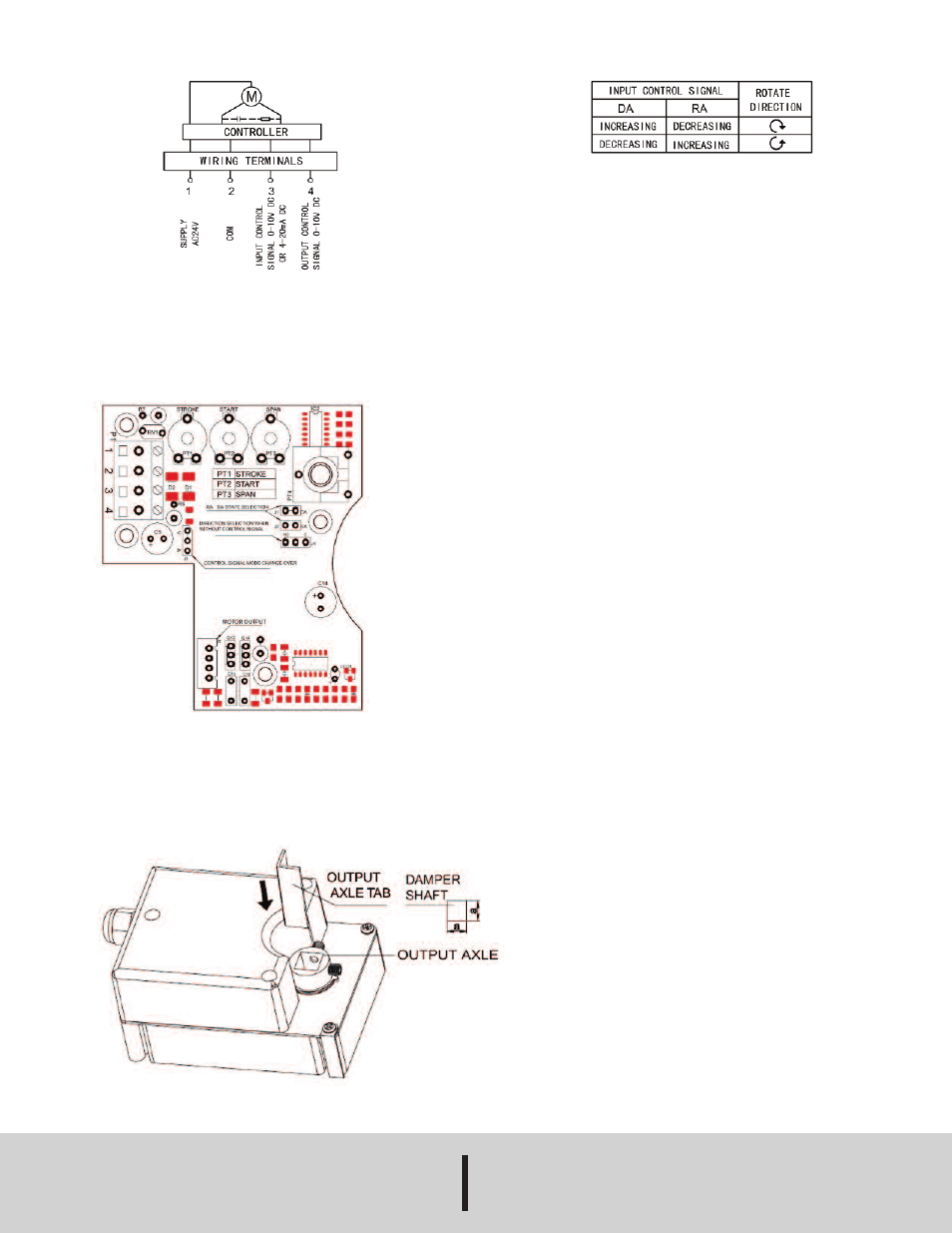

WIRING DIAGRAM

Set Up

• Set jumper J1 or J2 to proper selection for reverse or direct acting. See

Chart 1: Actuator Action above for more detail.

• Set jumper J3 for Voltage or Current input control signal.

• Set jumper J4 for actuator direction on loss of control signal.

• Potentiometer PT1 adjusts the stroke of the actuator.

Square shaft installation

Before installation, the aluminum gasket should be put into the hole of

Output Axle. Fix with square damper shaft. The rotating angle of the

actuator can be set by internal potentiometer. The match between

working range and feedback signal is automatically done by the actuator.

CHART 1: ACTUATOR ACTION

MAINTENANCE

Upon final installation of the Series DDC Non-Spring Return Direct

Coupled Actuator, no routine maintenance is required. A periodic check

of the system calibration is recommended. The Series DDC is not field

serviceable and should be returned if repair is needed (field repair

should not be attempted and may void warranty). Be sure to include a

brief description of the problem plus any relevant application notes.

Contact customer service to receive a return good authorization number

before shipping.

a = .4˝ (10 mm)

or

.5˝ (13 mm)

DWYER INSTRUMENTS, INC.

Phone: 219/879-8000

www.dwyer-inst.com

P.O. BOX 373 • MICHIGAN CITY, INDIANA 46360, U.S.A.

Fax: 219/872-9057

e-mail: [email protected]

©Copyright 2014 Dwyer Instruments, Inc.

Printed in U.S.A. 5/14

FR# R3-443451-40 Rev. 2