Dwyer SSR-15 User Manual

Page 2

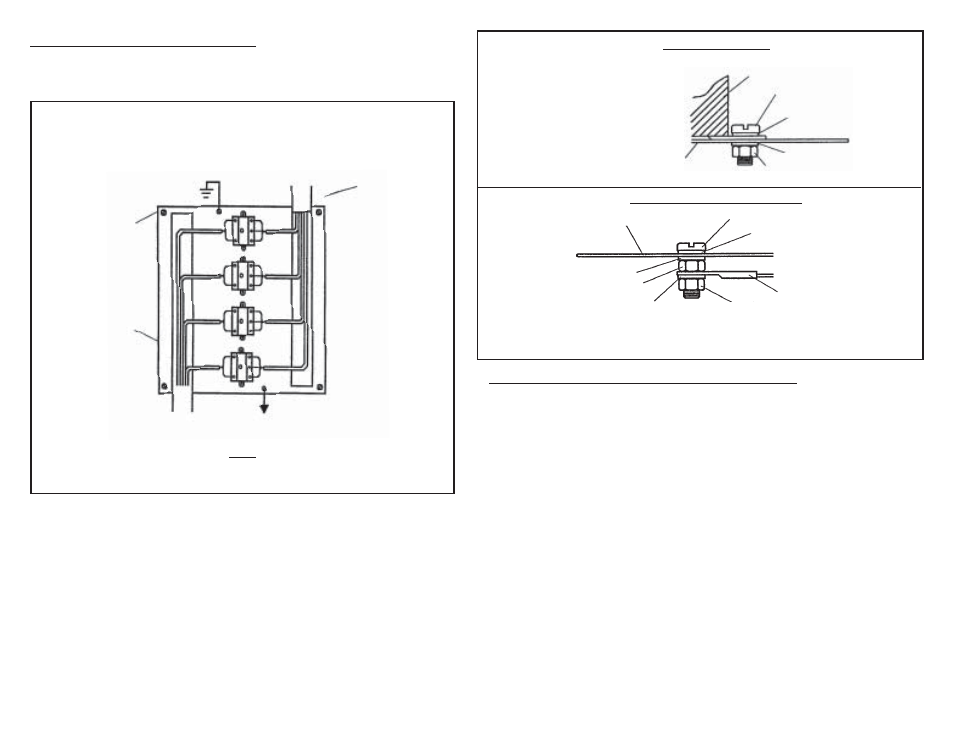

2. Mounting and Enclosure Considerations:

Field wiring of intrinsically safe circuits is to be segregated from non-

intrinsically safe wiring by use of suitable barriers, separate wireways or

trays (See Fig. 2). Wire insulation to be .010", minimum.

Intrinsically safe and non-intrinsically safe connection points should be

located sufficiently apart to prevent any possibility of bypassing or miswiring

during installation or servicing of equipment.

The enclosure shall contain a cautionary statement as follows: “CAUTION:

ANY SUBSTITUTION OF COMPONENTS MAY IMPAIR INTRINSIC

SAFETY”.

The SSR mounting bracket must be grounded to insure intrinsic safety.

Resistance between bracket and ground electrode should be below one

ohm. (See Fig. 3 and Fig. 4 for recommended selection of grounding

hardware and refer to Article 250 of the National Electrical Code for methods

and practices.)

B.

C.

D.

A.

3. Installation of Sensor Switch and Running of Field Wiring:

A. It is expected that the installation will be in accordance with Article 504 of the N.E.C.,

ANSI/NFPA 70 and/or C.E.C. Part 1*.

*Note: This is a CSA requirement. C.E.C. = Canadian Electrical Code.

B. The nature of the sensor switch must be that it is a non-voltage-producing, essentially

resitive device, containing no energy-storing components. (Simple Apparatus -flow

switches, level switches, pressure switches.)

C. The conductors of the intrinsically safe circuit should be sealed in a rigid metal conduit

at the point where the wiring enters the hazardous area. The wiring and contacting

device should be such that conductive dusts in the area will not close the circuit in

place of the contacts.

D. Hazardous area field wiring will store energy due to distributed capacitance and

inductance in proportion to its length. It is therefore recommended that the characteris-

tics (available from the manufacturer) of the cable be known and judged against the

length of run and atmosphere of exposure. The conservative chart on the next page is

presented as a requirement in determining the limits of reactance for signal loops in

the hazardous area wiring for the SSR series.

E. Whenever possible, the actual measured parameters should be used in making the

determination of allowable length.

F. Shielded cable is not required; but if used in the application, the shield must be returned

to ground - the same as the SSR mounting bracket.

G. Non-intrinsically safe wiring cannot be run in conduit or open raceways together with

intrinsically safe wiring.

Fig. 3. Unit Mounting Detail

* Note:

Lockwashers to be internal

or external tooth-type.

SSR-15

#10 Screw

* #10 Lockwasher

#10 Nut

Mounting Plate

* #10 Lockwasher

Fig. 4. Mounting Plate Grounding Detail

Mounting Plate

Screw

* Lockwasher

* Lockwasher

* Lockwasher

Nut

Nut

Terminal Lug

Notes:

1. Grounding Hardware to be #8 or larger and Stainless Steel.

2. * Lockwashers to be internal or external tooth-type.

Earth Ground

(2 Places)

Common

Earth Ground

Mounting Plate

Non-Intrinsically

Safe Wiring

Intrinsically Safe

Wiring to Sensors

Located in Hazardous

Area

Resistance to Gnd.

must be less than 1

ohm from mounting

screw or bracket to

earthing member to

insure integrity.

Fig. 2.

Multiple SSR units Grouped on

Common Earth-Grounded Mounting Plate

Located in Non-Hazardous Area

Note:

All intrinsically safe wiring must be segregated from non-intrinsically

safe wiring and shall have a minimum insulation thickness of .010”.