Dwyer instruments, inc – Dwyer DPL110 User Manual

Page 2

©Copyright 1999 Dwyer instruments, Inc

Printed in U.S.A. 7/99

FR# R1-443103-00

DWYER INSTRUMENTS, INC.

Phone: 219/879-8000

www.dwyer-inst.com

P.O. BOX 373 • MICHIGAN CITY, INDIANA 46361, ,U.S.A. Fax: 219/872-9057

e-mail: [email protected]

Lit-By Fax: 888/891-4963

3. Attach the white lead between the lower level probe

terminal and terminal six (6) on the socket mount.

4. Attach the red lead between the upper level probe

terminal and terminal eight (8) on the socket mount.

5. Tighten compression fitting until cable cannot be

pushed into sensor head.

Warnings

Install controller according to applicable electrical

codes. Do not connect directly to line voltage. Not for

use in hazardous (explosive) environments. Do not

exceed pressure and temperature ratings.

Pump-Up Operation

Pump-Up Operation is designed to keep tank levels at

the high electrode position. The controller output

switches from normally open to normally closed when

the liquid level falls below the lower level electrode.

When the switch is normally closed, the load to a pump

or solenoid valve is turned on and the tank begins to

refill. The pump or solenoid valve remains on until the

liquid level reaches the high level electrode.

1. Connect sensor head to controller as discussed

above.

2. Connect the device power supply to terminal 1. (The

device power supply is the voltage that is required

by the device (pump, valve, etc.) being turned on or

off. This voltage can be either AC or DC Volts and up

to 220 VAC max.) See figures 2 and 3.

3. Connect one end of the pump/valve to terminal 4 and

the other end to the device power supply.

4. Connect 110 VAC power to terminal 2 and 7.

5. Snap the controller onto the socket.

Probe Sensitivity Adjustment

Because conductivity varies widely among liquids, the

controller is adjustable for sensitivity in different liquids.

An adjusting screw is located on the front face of the

controller. 1 is the least sensitive setting for highly

conductive fluids. 9 is the most sensitive setting for

least conductive fluids. Typically, the sensitivity should

be set at 5.

Maintenance/Repair

After final installation of the Model DPL Dual Point Level

Switch, no routine maintenance is required. A periodic

check of system calibration is recommended. These

devices are not field repairable and should be returned

to the factory if recalibration or other service is required.

After first obtaining a Returned Goods Authorization

(RGA) number, send the material, freight prepaid, to the

following address. Please include a clear description of

the problem plus any application information available.

Dwyer Instruments, Inc.

Attn: Repair Department

102 Highway 212

Michigan City, IN 46360

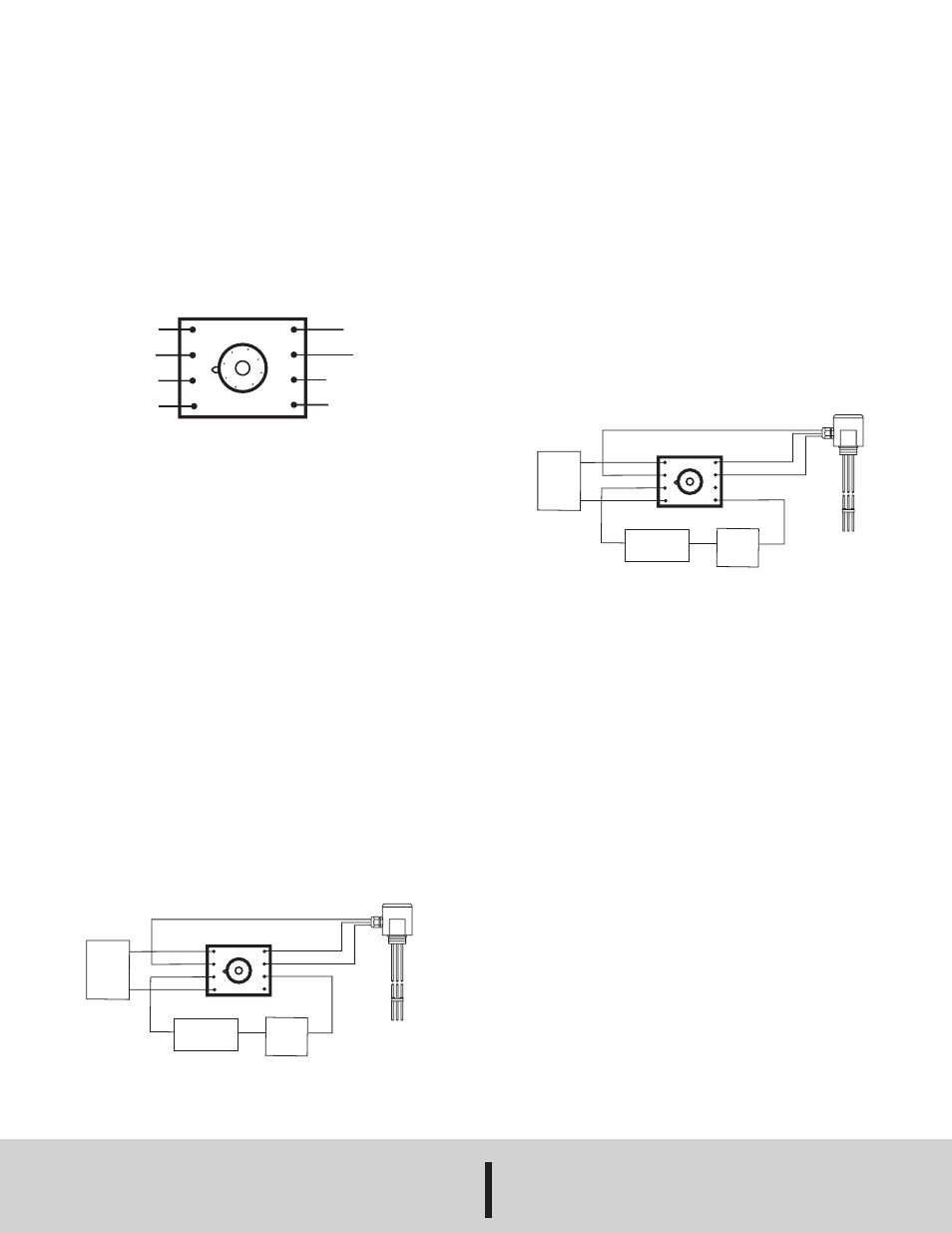

7

8

1

2

6

5

4

3

Upper Level Probe

110 VAC (White)

Device Power Supply

110 VAC (Black)

Lower Level Probe

Probe Common

Normally Closed

Normally Open

Figure 2

7

8

1

2

6

5

4

3

Pump

or

Valve

Device

Power Supply

Pump-Up Operation

110 VAC

Power

Supply

Figure 3

7

8

1

2

6

5

4

3

Pump

or

Valve

Device

Power Supply

Pump-Down Operation

110 VAC

Power

Supply

Figure 4

Pump-Down Operation

Pump-Down Operation is designed to keep tank levels

at the low electrode position. The pump or solenoid

valve will start when the liquid level reaches the high

level electrode and remain on until the level reaches the

lower level electrode.

1. Connect sensor head to controller as discussed

above.

2. Connect the device power supply to terminal 1. (The

device power supply) is the voltage that is required

by the device (pump, valve, etc.) being turned on or

off. This voltage can be either AC or DC Volts and up

to 220 VAC max.) See figure 2 and 4.

3. Connect one end of the pump/valve to terminal 3 and

the other end to the switched voltage return.

4. Connect 110 VAC power to terminal 2 and 7.

5. Snap the controller onto the socket.