Amerex 05608 User Manual

Page 10

9

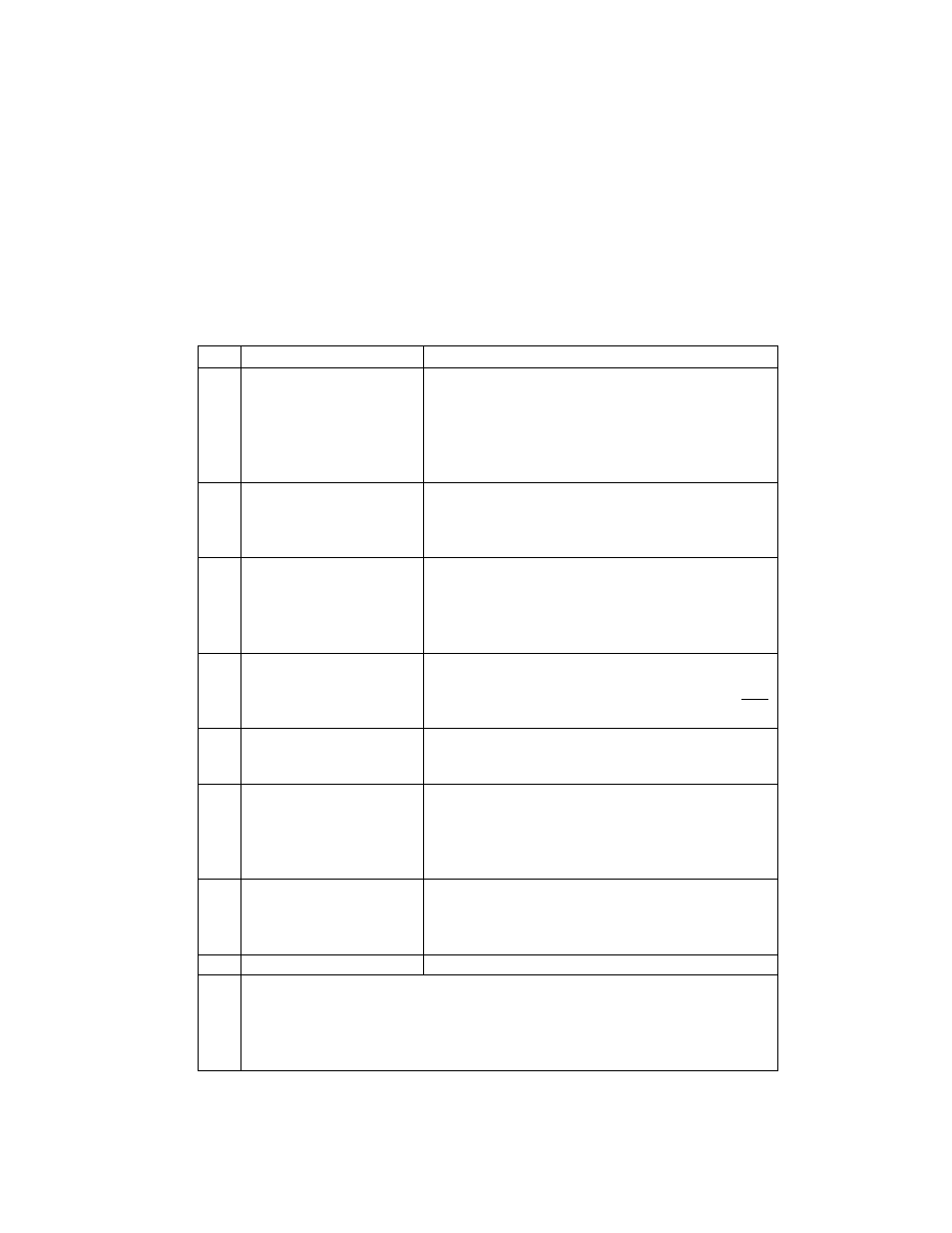

TROUBLESHOOTING GUIDE

WARNING:

Before attempting to correct any leakage problem, be sure that the agent

cylinder and hose are completely depressurized. Check to determine the

source of a leak before the extinguisher is depressurized. Leakage repairs

will require depressurization and removal of the valve assembly.

Depressurize by discharging into a Closed Recovery System or inverting

the extinguisher. After depressurizing the extinguisher and correcting the

problem, it will be necessary to clean all valve parts thoroughly.

PROBLEM

CORRECTIVE ACTION

1.

Leak at collar o-ring

Remove valve assembly, remove and

discard o-ring, clean collar and lube lightly

with Visilox V-711. Clean o-ring groove on

valve and install new collar o-ring. Lubricate

with Visilox V-711.

2.

Leak at agent fill cap

Remove cap, clean threads thoroughly and

install new o-ring. Lubricate o-ring with

Visilox V-711.

3.

Leak through valve

Check valve stem seating area for scratches

or foreign matter. Clean seating area with a

tooth brush and soft cloth. Install new valve

stem assembly.

4.

Leak

at

"bleeder"

valve.

Remove and reinstall valve using Teflon

tape on threads. Note: "Bleeder" valve cap

must be installed to prevent leakage.

5.

Leak around gauge

threads

Remove gauge*, clean threads and reinstall

using Teflon tape on the gauge threads.

6.

Defective gauge

Remove defective gauge* an install the

proper Amerex pressure gauge (P/N 05225

240 psi) using Teflon tape on the gauge

threads.

7.

Leak in the cylinder

Contact

Amerex

if

under

warranty,

otherwise mark "REJECTED" and remove

from service or return to owner.

* Pressure gauge threads are coated with a special epoxy at the

factory. For easy removal, soak the valve assembly in hot water

(180°F) for two to four minutes. Remove gauge with a thin 7/16"

open end wrench.