Archived – Seametrics IP80-Series User Manual

Page 8

Page 8

PVc/Steel

Sch. 40

PVc/Steel

Sch. 80

Stainless

Steel (10S)

Stainless

Steel (40S)

copper tubing

(type L)

copper tubing

(type K)

brass Pipe

Duct. Iron

(class 52)

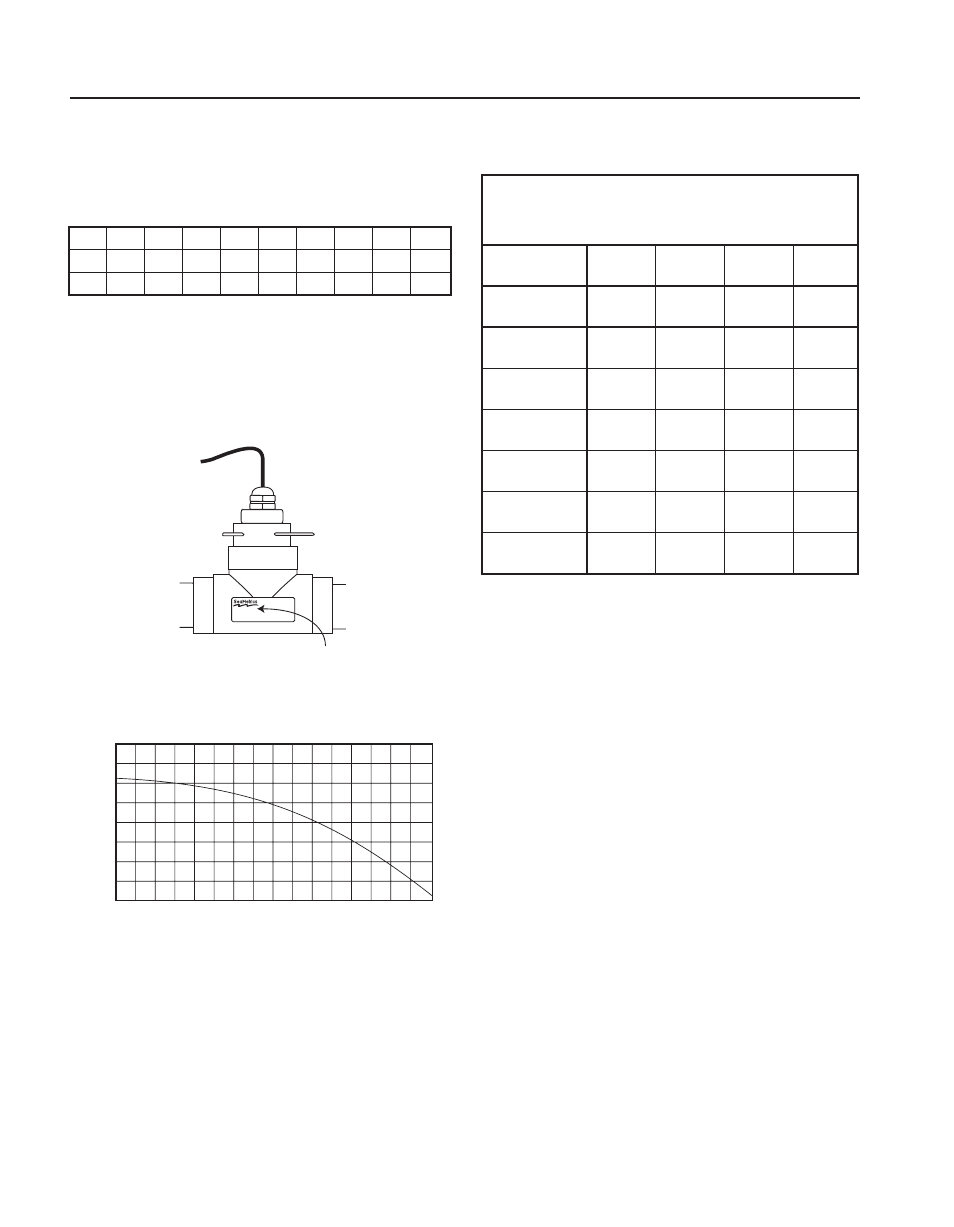

IP80-SERIES K-FactORS

FOR SaDDLE & WELDOLEt FIttINGS

3"

4"

6"

8"

28.92

32.368

25.614

28.920

31.386

32.212

29.033

23.548

16.790

18.591

14.996

16.790

17.847

18.294

17.009

15.282

7.412

8.215

6.747

7.412

7.981

8.272

7.268

6.913

4.275

4.684

3.926

4.275

4.563

4.736

4.254

3.485

Minimum Flow. As with any other flow sensor, there is

a rate below which the IP80-Series sensor cannot read.

Checktheflowratetablebelowfortheminimumflowrate

detectablebythesensorforagivenpipesize.

calibration (“K-factor”). The K-factor represents the

numberofpulsespergallonthemeterproducesduringa

flowtest.Thisnumbermustbeenteredintoyourelectronic

controltomakeitreadproperly.IftheIP80-Seriesmeteris

orderedwithatee fitting,itisfactory-calibratedinthefitting

andtheK-factorisindicatedontheside(seebelow).

£ддО£Уx

n£/*Óää

\КxО°И

Find Your K-Factor Here

Field calibration.Itispossibletofield-calibrateanIP80-

Series flow sensor to determine an accurate K-factor in

the actual installation. The reason for doing this would

betocompensateforanunusualcondition,forinstance,

applicationswithhigherviscosityfluid(IPmetersarecali-

bratedforwateruse)orwhichlackadequatestraightpipe

aheadofthemeter.FieldCalibrationproceduresarede-

scribedinaTechnicalBulletinonourwebsite(www.seam-

etrics.com).

Ifasaddle or weld-type fittinghasbeenordered,seethe

tablebelowfortheproperK-factor.

Flow Range (GPM)

1/2" 3/4" 1" 1-1/2" 2"

3"

4"

6"

8"

Min 0.28 0.5 0.8 1.9 3.1 6.9

12

27 46.8

Max 28

50

80 190 314 691 11902700 4680

OPERatION

50

100

150

200

60˚

70˚

80˚

90˚ 100˚

110˚

120˚ 130˚

140˚

P.S.I.

PRESSuRE VS. tEMPERatuRE (PVc/Polypro)

ARCHIVED

(Includes Dates Before 1/1/201

1)