Archived – Seametrics IP80-Series User Manual

Page 4

Page 4

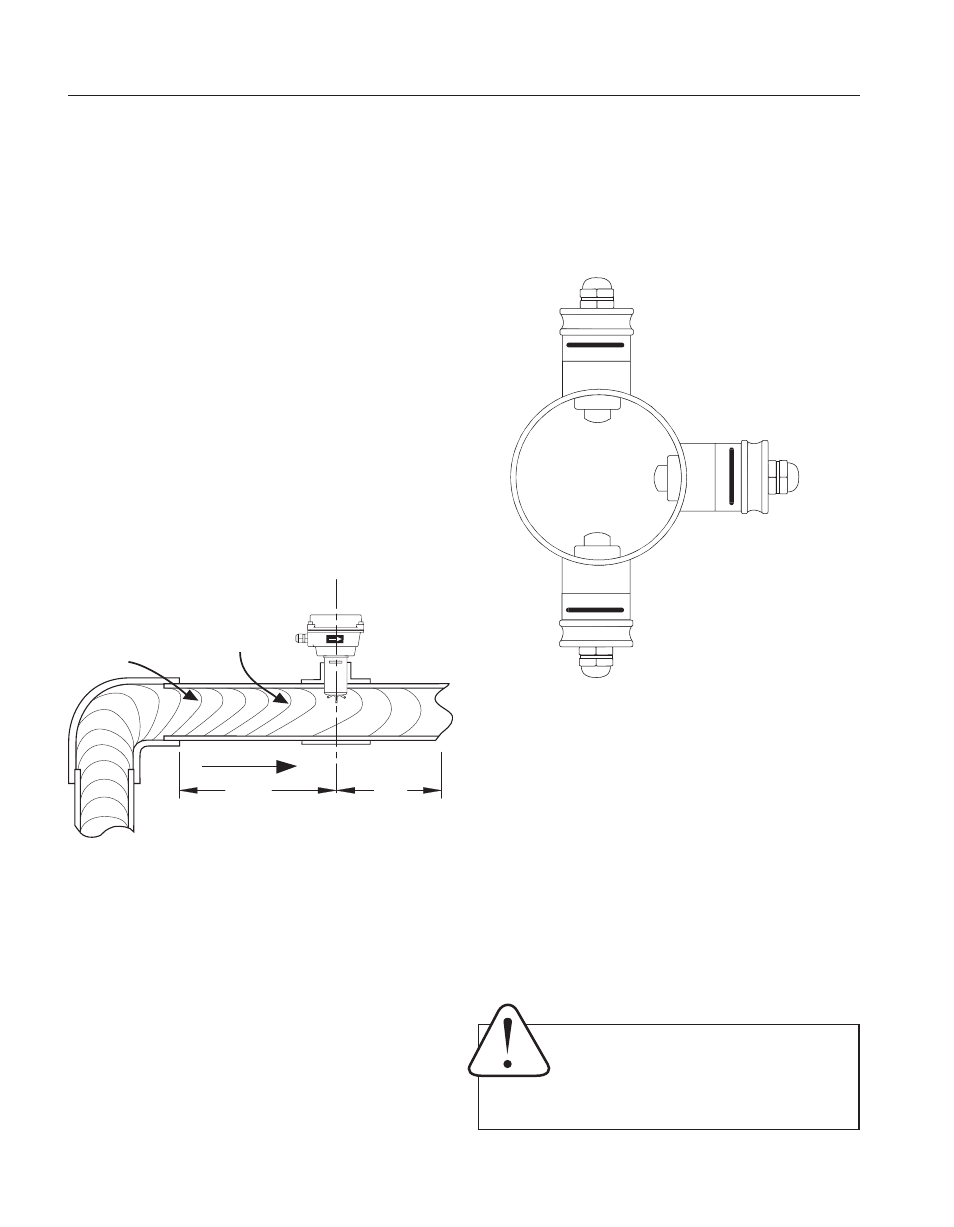

Fitting Installation. Stainless steel and brass fittings

havefemalepipethreads,requiringtheappropriatemale

threadedfittings.Saddlefittingsrequireaholetobecut

inthepipe(recommendedholesizeis1-3/4”).Before

cuttingintothepipe,observethedrawingbelowtochoose

yourmeterorientation.

PVc Fittings. A PVC fitting is usually installed by sol-

ventwelding.PVCteesaresuppliedwithsomeupstream

straight pipe, less than the recommended straight pipe

requirements.Itisnotadvisabletoconnectdirectlytothe

endofthesefittingswithaflowdisturbingdevice(valve,

elbow),butratheraddstraightpipetotheendofthese

fittings to meet the straight pipe requirements for your

application.

Meter Installation. After the meter fitting is installed

inthepipeline,themetercanbeinstalledinthefitting.

Pressthemeterintothefittingasfarasitwillgo.Retain

themeterinplacebyinsertingtheu-pin.Thepincanbe

installedfromeitherside.Itmaybenecessarytorotate

theprobebackandforthslightlytostartthepinintothe

slotsontheprobe.Slidethepininasfarasitwillgo.

Insertion Depth.TheIP80-Seriesarefixed-depthmeters

thatmustbeusedwithmatchedfittingsappropriatetothe

applicationandpipesize.Thisensuresthattheflowsen-

sorisinstalledatthecorrectinsertiondepthtomeasure

theaverageflowvelocityofthestream.

K-Factor.Eachflowsensor/teefittingpairiswetcalibrated

atthefactoryandmarkedwiththecorrectK-factor.Saddle

fittingscannotbefactory-calibratedattheproperinsertion

depth because the fitting must first be installed on the

pipeinthefield;therefore,K-factorsforsaddlefittingsare

derivedthroughtestingwithstandardpipeschedulesand

includedwiththemeter.InPVC,however,itispossibleto

orderasaddlepre-installedonastandardlengthofpipe,

andthefittingcanbewet-calibratedinthiscase.

Straight Pipe.Straightpipeofatleast10diametersup-

stream and five diameters downstream of the meter is

stronglyrecommendedforproperaccuracy.Thisisneces-

sary because the shape of the velocity profile changes

astherateincreasesaroundanelbow;placingthemeter

tooneartheelbowcausesadistortedreading.Additional

straightrunmaybeneededunderspecificadversecircum-

stances(seenextpage).

If you can’t provide enough straight run to smooth out

thevelocityprofile,somedecreaseinaccuracymayresult.

Thisdoesnotmeanthemeter’sreadingismeaningless,

however.Insomeapplications(e.g.,controlsystem,valve

operation) a repeatable reading may be more important

thanahighlyaccurateone.

INStaLLatION

caution: Never remove the u-clip retainer

when the pipe is under pressure. Always

remove pressure from the pipe before you

attempttoremovethemeter.Removalunderpres-

suremayresultindamageorseriousinjury.

5X

DiameterMinimum

(SeeBelow)

DIStORtED FLOWS

Distorted

FlowProfile

FasterFlow

CausesMeter

ToReadHigh

FLOW

10X

DiameterMinimum

(SeeBelow)

BEST

Okay, if no air in pipe

Okay, if no sediment in pipe.

POSItIONING tHE MEtER

ARCHIVED

(Includes Dates Before 1/1/201

1)