Ar ch ive d, Includes dates before 5/05) – Seametrics EX100-200 Series v.1 User Manual

Page 5

Page 3

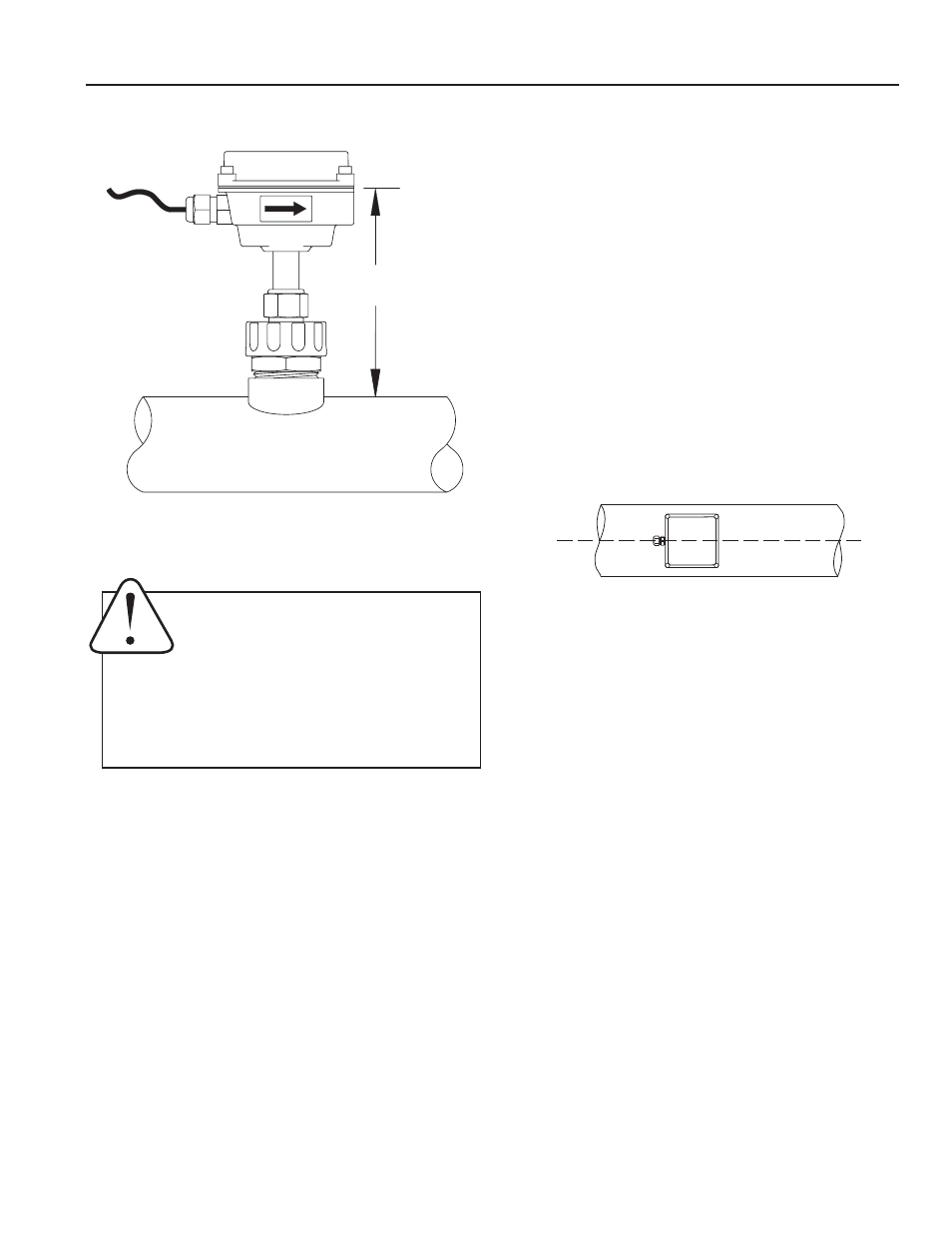

INSTALLATION

Depth Setting. It is important for accuracy that the

sensor be inserted the correct depth into the pipe.

Follow these steps:

1. In Table 1, find the model of sensor which you have.

Take Dimension C from this table for the pipe size.

2. Subtract wall thickness of your pipe to find Dimension

D. Use Table 2 if you do not know the thickness.

3. Measuring from the outside of the pipe to the joint in

the housing, as shown in the diagram, adjust the sensor

to Dimension D and tighten enough to hold it there.

4. Line the conduit housing with the centerline of the

pipe, as shown.

5. Check Dimension D one more time.

6. Tighten the compression nut fully.

"D"

Caution!

Never attempt to remove a

flow sensor when there is pressure in

the pipe. Loosen the locking collar

slowly to release any trapped pressure. If fluid

sprays out when removing the sensor, stop turn-

ing and depressurize the pipe. Failure to do so

could result in the sensor being thrown from the

pipe, resulting in damage or serious injury.

PROPER DEPTH SETTING

AR

CH

IVE

D

(Includes Dates Before 5/05)