Ar ch ive d, Includes dates before 5/05) – Seametrics EX100-200 Series v.1 User Manual

Page 4

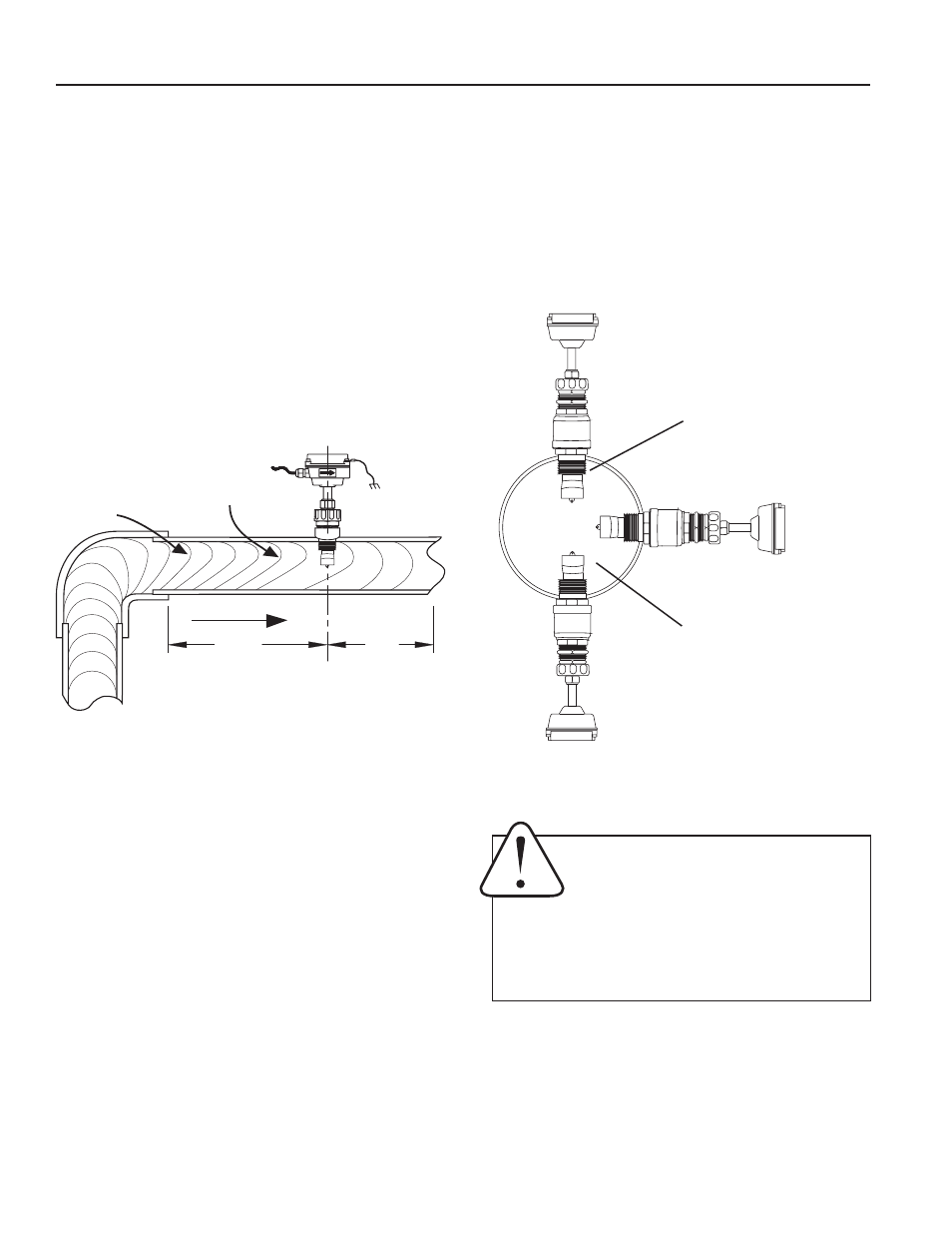

Piping. For best results, the EX sensor should be in-

stalled with at least ten diameters of straight pipe

upstream and five downstream. Cer tain extreme situations

such as par tially-opened valves are particularly difficult

and may require more straight diameters upstream. The

101 and 201 sensors are supplied with a 1-1/2" male

pipe thread fitting. The 115 and 215 sensors have a 2”

NPT thread, for compatability with the 2” isolation valve.

Any fitting which provides the matching NPT female thread

may be used. The installation procedure compensates

for differences in height of the fitting.

Horizontal is the preferred installation orientation, since it

improves low-flow per formance and avoids problems with

trapped air. Bottom, top, and ver tical pipe installations

are all acceptable if required by the piping layout.

Immersion. The 100/200 Series standard sensors are

not designed for continuous underwater operation. If this

is a possibility, as in a flooded vault, a unit modified for

immersion should be specified.

Fitting Installation. First cut a minimum 1-3/4" hole in

the pipe. If possible, measure the wall thickness and write

it down for use in depth setting, below. Then install the

threaded fitting (saddle, weldolet, etc.) on the pipe.

Page 2

Caution: These flow sensors are not

recommended for installation down-

stream of the boiler feedwater pump

where installation fault may expose the flow

sensor to boiler pressure and temperature.

Maximum recommended temperature is 130

°F

(Plastic), 200

°F (Metal).

INSTALLATION

DISTORTED FLOWS

Distorted

Flow Profile

Faster Flow

Causes Meter

To Read High

FLOW

10X

Diameter Minimum

5X

Diameter

Minimum

Fair

(Unacceptable position

if air is present)

Best

Position

Fair

(Unacceptable position if

fluid contains sediment)

POSITIONING THE METER

Meter Installation. Remove the threaded adapter from

the sensor. Using a thread sealant, install the adapter in

the pipe fitting.

Do not overtighten. Slide the meter through

the adapter fitting. Engage the locking collar threads and

turn until the collar stops, about 1-1/2 to 2 turns.

AR

CH

IVE

D

(Includes Dates Before 5/05)