NOSHOK 627 Series Pressure & Level Transmitters User Manual

Page 2

FMRC 3600, 3610, 3611, 3810 (including

supplement #1), ISA-S12.0. 01, IEC 60529 (including

amendment #1)

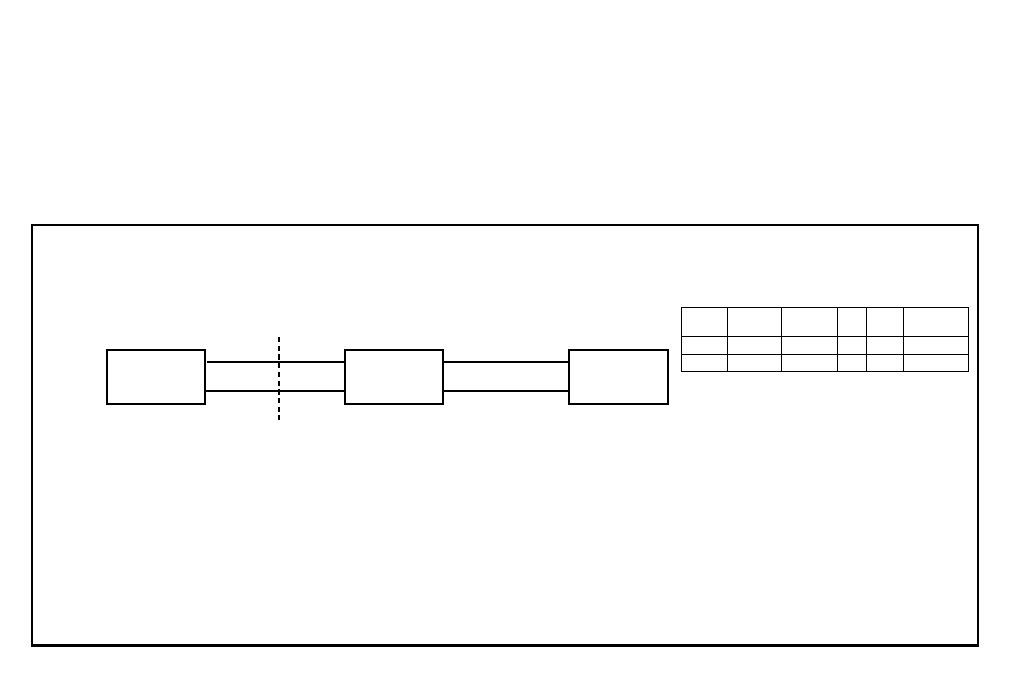

Installation and Commissioning

Model 625 pressure transmitter is connected to

the pressure source using the the threaded stainless

steel pressure port. Several pressure port sizes are avail-

able.

Model 626 pressure transmitter incorporates a stain-

less steel (or optional material) diaphragm at the end of

the pressure connection, providing a flush diaphragm

configuration. It is connected to the pressure source

General

NOSHOK Model 625, 626 and 627 transmitters are

approved for use in hazardous location applications as

follows:

Intrinsically Safe, entity approval for Class I, II and III,

Division 1, Groups A, B, C, D, E, F and G; and Class I Zone

0 Aex ia IIC

Dust Ignition-proof for Class II and III, Division 1,

Groups E, F and G

Non incendive for Class I, Division 2, Groups A, B, C

and D

using the G1/2 B or G1 B threads directly or through the

use of the available weld on adapters. Model 627 is a

submersible level transmitter and is suspended by the

attached cable in a tank. The hydrostatic pressure

produced by the liquid rising above the location of the

level transmitter is directly related to the actual liquid

level. Unless the metal body of the model 627 is

grounded directly in the mounting of the transmitter,

the drain wire in the cable needs to be grounded to a

suitable system ground. It is essential to do this for the

built in noise protection to be effective.

ENTITY PARAMETERS:

Vmax = 30 V, 1max = 100 mA, P1 = 1 W

Ci = 22 nF (FLYING LEADS: + 0.2 nF/m). Li = 0.1 mH (FLYING LEADS: + 2 nH/m)

NOTES:

1. THE INTRINSIC SAFETY ENTITY CONCEPT ALLOWS THE INTERCONNECTION OF TWO FM APPROVED INTRINSICALLY SAFE DEVICES WITH ENTITY PARAMETERS

NOT SPECIFICALLY EXAMINED IN COMBINATION AS A SYSTEM WHEN: Uo OR Voc OR V1 ≤ Vmax, 1o OR 1sc OR 1t ≤ 1max, Ca OR Co ≥ C; + Ccable, La OR Lo ≥ Li + Lcable, Po ≤ Pi

2. DUST-TIGHT CONDUIT SEAL MUST BE USED WHEN INSTALLED IN CLASS II AND CLASS III ENVIRONMENTS

3. CONTROL EQUIPMENT CONNECTED TO THE ASSOCIATED APPARATUS MUST NOT USE OR GENERATE MORE THAN 250 Vrms OR Vdc

4. INSTALLATION SHOULD BE IN ACCORDANCE WITH ANSI / ISA RP12.6 ″ INSTALLATION OF INTRINSICALLY SAFE SYSTEMS FOR HAZARDOUS (CLASSIFIED) LOCATIONS AND THE NATIONAL ELECTRICAL CODE θ

(ANS 1 / NFPA70) SECTIONS 504 AND 505

5. THE CONFIGURATION OF ASSOCIATED APPARATUS MUST BE FACTORY MUTUAL APPROVED UNDER ENTITY CONCEPT

6. ASSOCIATED APPARATUS MANUFACTURER’S INSTALLATION DRAWING MUST BE FOLLOWED WHEN INSTALLING THIS EQUIPMENT

7. THE 625, 626, 627 SERIES ARE APPROVED FOR CLASS I, ZONE 0 APPLICATIONS. IF CONNECTING AE x [ib] ASSOCIATED APPARATUS OR AEx ib I.S. APPARATUS TO THE 625, 626 AND 627 SERIES THE

I.S CIRCUIT IS ONLY SUITABLE FOR CLASS I, ZONE I OR CLASS I, ZONE 2 AND IS NOT SUITABLE FOR CLASS I, ZONE 0 OR CLASS I, DIVISION I HAZARDOUS (CLASSIFIED) LOCATIONS

8. NO REVISION TO DRAWING WITHOUT PRIOR FACTORY MUTUAL RESEARCH APPROVAL

Internal

Hirschmann

Cable

M12

Bendix Junction Box

+Supply

1

Red/Brown

1

A

1

+Output

2

Black/Green

3

B

2

4 mA to 20 mA 2-WIRE SYSTEM

NON-HAZARDOUS LOCATION

HAZARDOUS (CLASSIFIED) LOCATION

CLASS I, ZONE O, GROUP IIC

CLASS I, DIVISION I, GROUPS A, B, C, AND D

CLASS I, DIVISION I, GROUPS E, F AND G

CLASS I

(NOTE 2)

625, 626 and 627 SERIES

ASSOCIATED APPARATUS

CONTROL EQUIPMENT

(NOTE 5)

(NOTE 6)

(NOTE 7)

(NOTE 3)