KROHNE LS 4100 EN User Manual

Page 9

03/2002

LS 4100/LS 4150

9

Transport

Do not hold level switch on the tuning fork. The tuning fork can be damaged.

Polished version LS 4150

Treat instruments with polished tuning fork LS 4150 very carefully and do not touch the polished

surface. Unpack LS 4150 directly before mounting. Insert LS 4150 carefully into the provided

opening and avoid contact with vessel parts.

Cable entries

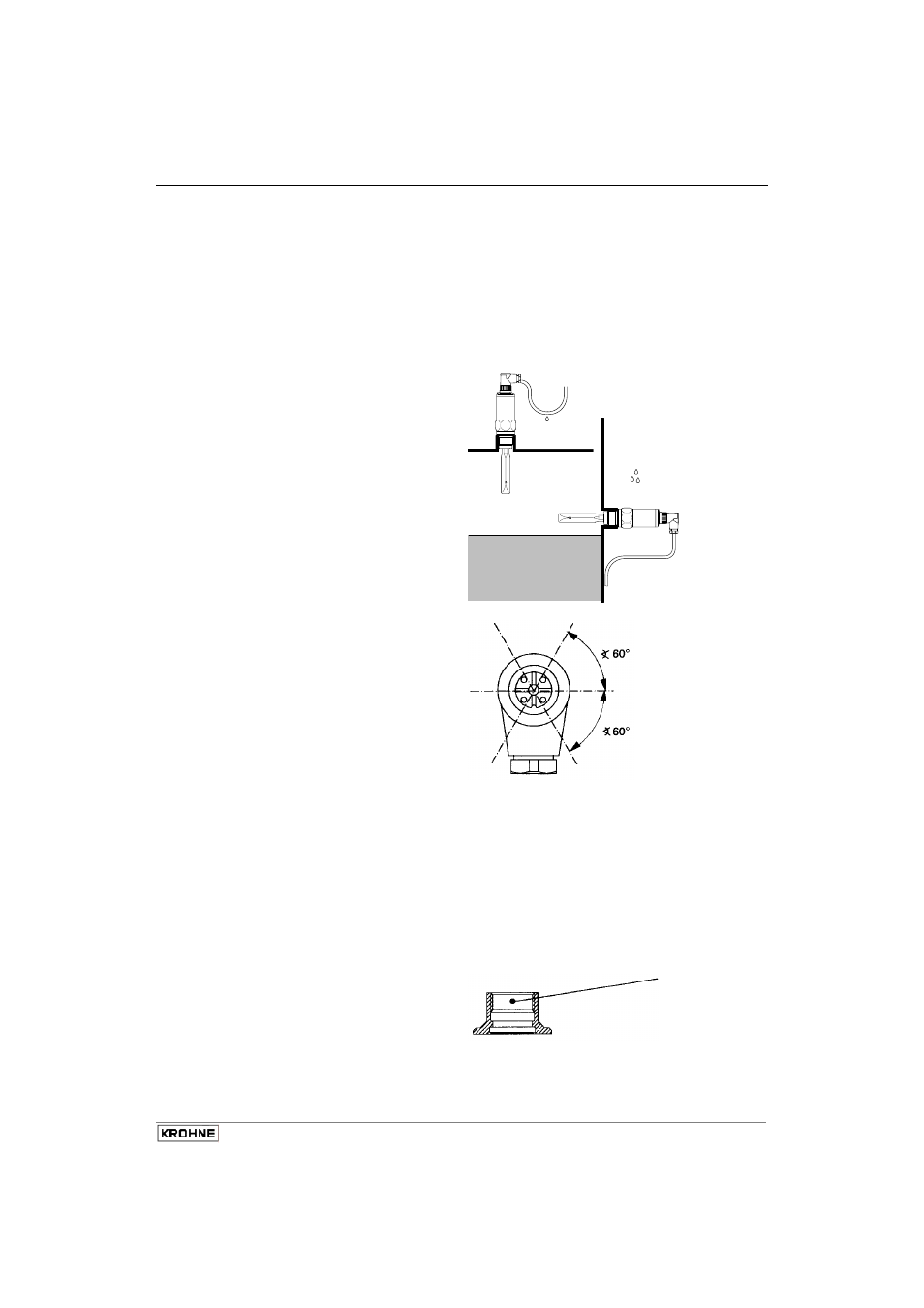

When mounting outside, on cooled vessels or in

humid areas in which e.g. cleaning is done with

steam or high pressure, the seal of the cable

entry is especially important. Use cable with

sufficient wire cross-section and tighten the

cable entry. For cables with too small wire

cross-section, a suitable reduction piece must

be used to ensure tightness of the cable entry.

Two seal rings are attached to the instrument to

ensure tightness also of cables with smaller

diameter. Use the smallest possible seal ring.

To avoid humidity ingress, the cable entry

should point downwards (see fig. 2.4).

Proceed as follows: Loosen the plug by

unscrewing the knurled ring. Loosen the

connection screw and remove the socket insert

out of the angular housing of the plug (see also

fig. 3.1 under "3.1 Connection instructions").

You can turn the angle housing of the plug in

60° steps (see fig. 2.5). With vertically mounted

LS 4150, loop the connection cable to the

instrument housing downwards so that rain and

condensation water can drain off.

Welded socket G 1 A

Level switch thread start is defined. This means that each is in the same position after screwing in.

Therefore remove the supplied seal from the thread of LS 4100/LS 4150. This seal is not required

when using a welded socket (G 1 A). Screw level switch into the welded socket.

You can determine the subsequent position of the level switch before welding (see also fig. 2.3).

Mark the appropriate position of the welded socket. Before welding, unscrew level switch and

remove the rubber ring from the socket.

An optional welded socket (G 1 A) is available

which is already provided with a notch. Weld

this socket with a marking facing up-wards.

Marking

Fig. 2.4

Fig. 2.5

Fig. 2.6