KROHNE H54 M4 EN User Manual

Page 7

7 H54 Installation and operating instructions

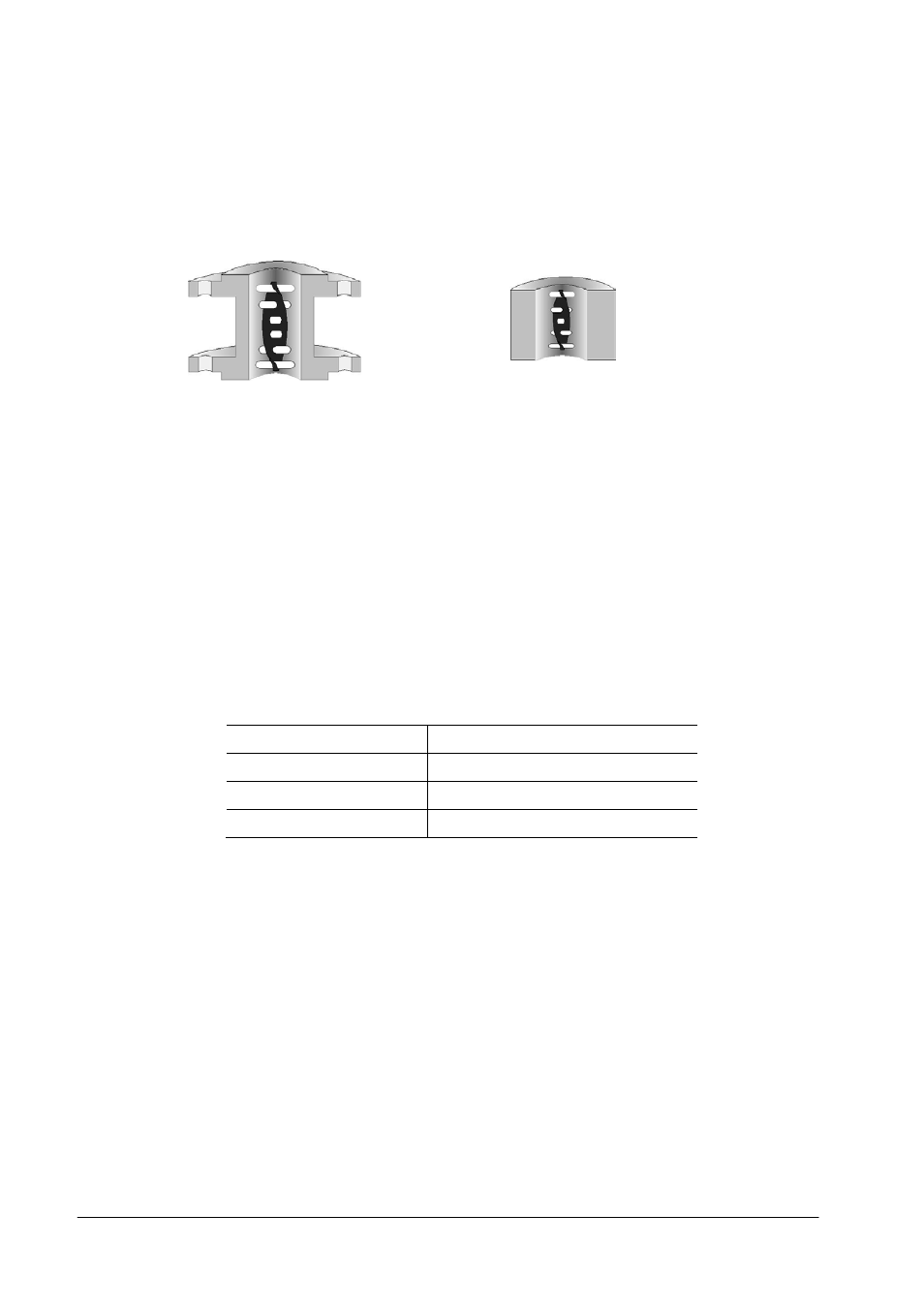

2.6 Magnetic

filters

Magnetic filters are used when the medium contains particles which can be influenced magnetically. The

magnetic filter is to be installed in the flow direction before the flowmeter. Magnetic bars are positioned

helically in the filter so that an optimal efficiency at a low pressure loss is achieved. All the magnets are

coated individually with PTFE to protect against corrosion. Two models are available:

Type F

Type FS

Fitting part with flange

Fitting part without flange

Overall length 100 mm

Overall length 50 mm

Materials

1.4571

(316

Ti)

2.7

Observance of the IP degree (NEMA Type) of protection

The following instructions are to be observed in order to observe the IP degree (Nema Type) of electrical

built-in parts.

- After the connecting cable has been introduced, tighten the outlet nut.

- All the cable glands which are not used remain closed with blanking plugs.

- Do not kink lines directly at the cable gland.

- Provide a drain bend

- The feed lines may not be subjected to mechanical strains. Refer to the description

of the electrical supplementary components for this device.

Cable glands / screwed glands: PG11 - line diameter 8 to 10mm

2.8 Start-up

A minimum operating pressure (pre-pressure) is required to operate the instrument.

Medium

Pressure loss : Operating pressure

Liquids

1 : 2

Gases (without damping)

1 : 5

Gases (with damping)

1 : 2

For the pressure losses please refer to the flow tables

2.9

Measurement of liquids

Vent the pipeline during starting-up in order to avoid liquid beats.

Open valves slowly!

2.10

Measurement of gases

Pulsations of the medium are to be kept away from the instrument.

In case of gases increase the operating pressure slowly.

The flow is to be varied by means of adjusting valves, so that the float is not subjected to blows

(e.g. through solenoid valves) thus ensuring that damage to the measuring unit cannot occur.

Instruments for measuring the flow rate of gases can be equipped with a gas damping, in order to avoid

possible compression vibrations of the float.

If vibrations nevertheless occur at the float, these can be eliminated by installing a throttle valve or a

suitable aperture hole (on request) behind the instrument.

A float damping is recommended for gas measurement.