KROHNE H54 M4 EN User Manual

Page 6

6 H54 Installation and operating instructions

2

Installation and Start-up

2.1

Protection during shipment

The sensing arm and cam plate are secured by a rubber band.

2.2

Prerequisite for the installation

The operating pressure of the plant may not exceed the value indicated on the rating plate.

Ensure that the parts coming into contact with the medium are compatible with the material. (For the list

of the materials please refer to the chapter on the materials of the instrument designs.)

The ambient and medium temperatures may not exceed certain maximum values.

The variable area flowmeter has to be installed vertically (float measuring principle - flow direction from

bottom to top).

In order to prevent distortions the connecting flanges have to face each other axially and in parallel.

2.3

Preparation of the pipeline

The pipeline is to be supported by suitable installation measures, so that vibrations at the pipeline are

prevented and axial stresses on the instrument are minimized.

A straight unimpeded inflow section of ≥ 5 x DN before the instrument and a straight

outflow section of ≥ 3 x DN behind the instrument are recommended.

Shutoff and control devices are to be positioned in the flow direction behind the measuring unit.

For installation recommendations please also refer to the Directive VDE/VDI 3513, Sheet 3.

2.4

Installation in the pipeline

The instrument may not be subjected to tensile or compressive stresses through the pipelines.

Immediately before carrying out the installation check whether the instrument is free of foreign particles.

Screws, bolts and seals (provided by customer) are to be selected in accordance with the pressure stage

of the connecting flange or the operating pressure.

The inside diameter of the flange deviates from the standard dimensions.

Flange seal standard DIN 2690 (ASME B16.21) can be applied without any limitation.

Align the seals. Tighten the nuts with the tightening torques of the corresponding pressure stage.

2.5 Fastening

torque

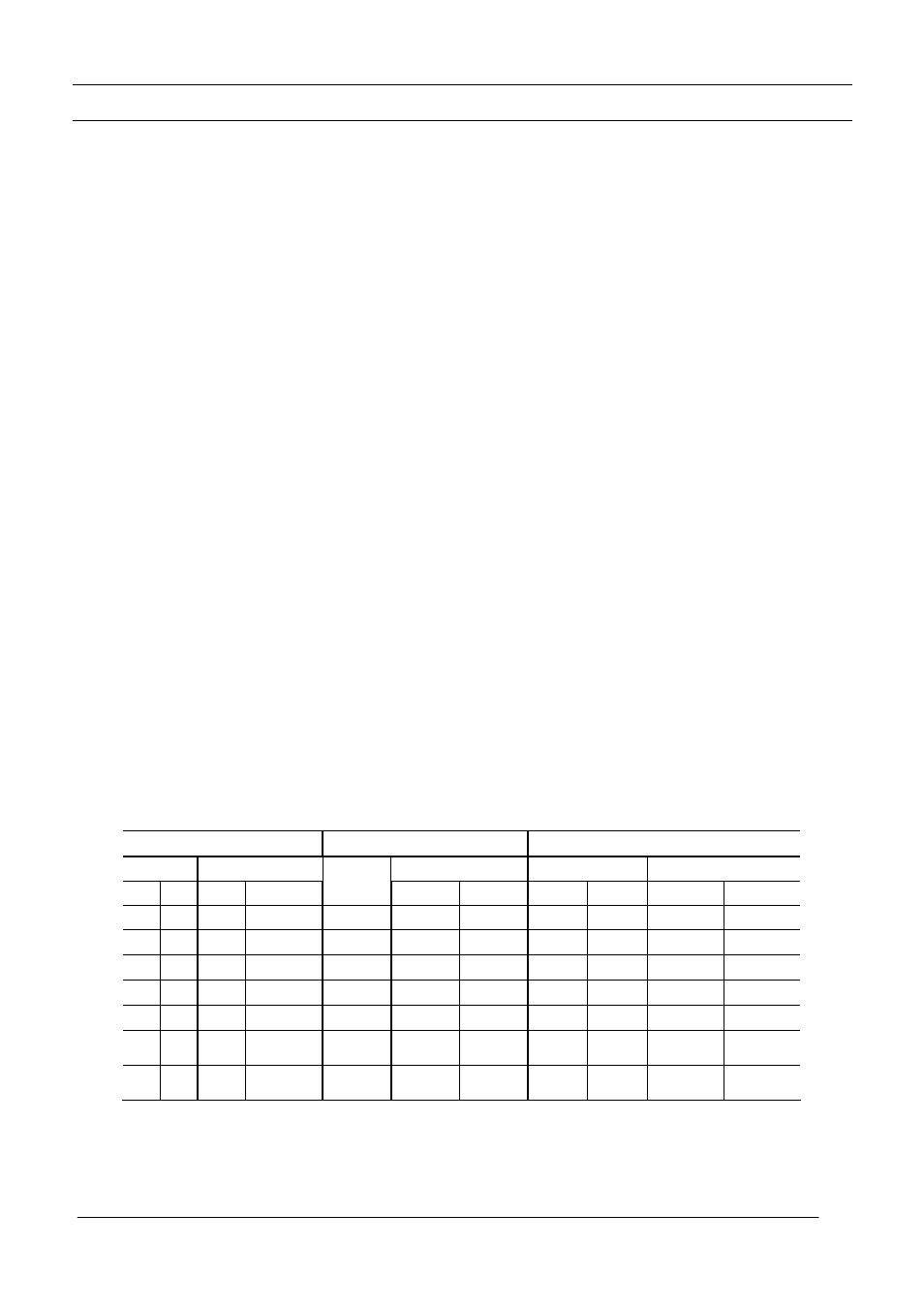

The flange bolts are to be tightened with the following maximum torques in case of measuring units with

PTFE liner or of measuring units with ceramic lining and PTFE sealing surface:

Nominal size to

Bolts

Max. tightening torque

DIN 2501

ASME B 16.5

DIN

ASME

DIN

ASME 150 lbs

DN PN Inch

lbs

150 lbs 300 lbs

Nm

ft·lbf

Nm

ft·lbf

15 40

½”

150/300 4 x M 12 4 x ½”

4 x ½”

9.8

7.1

5.2

3.8

25 40

1”

150/300 4 x M 12 4 x ½”

4 x

5

/

8

” 21 15

10

7.2

50 40

2”

150/300 4 x M 16 4 x

5

/

8

” 8

x

5

/

8

” 57 41

41

30

80 16

3”

150/300 8 x M 16 4 x

5

/

8

”

8 x ¾”

47

34

70

51

100 16

4”

150/300 8 x M 16 8 x

5

/

8

”

8 x ¾”

67

36

50

36

125 16

5"

150/300 8 x M 16 8 x

5

/

8

“

8 x ¾“

67

48

75

54

150 16

6"

150/300 8 x M 20 8 x ¾“

8 x ¾“

88

64

94

68