General, Items included with supply, Software history – KROHNE IFC 090 Converter PROFIBUS User Manual

Page 3: Profibus-pa

Supplementary Documentation IFC 090, IFC 090 i with PROFIBUS-PA

KROHNE Messtechnik GmbH & Co. KG ∑ Ludwig-Krohne-Str. 5 R D-47058 Duisburg

3/7

Tel.: 0203-301 309 R Fax: 0203-301389 ∑ e-mail: [email protected]

Control system (PLC)

Class 1 master

Segment

coupler/link

Analog I/O module

PROFIBUS-PA

4-20 mA

HART device

Power

Supply

PROFIBUS-PA

Segment

coupler/link

PROFIBUS-DP, up to 12 Mbit/s

Engineering or operation

control tool

Class 2 master

, 30) /&

1

2

3

4

5 6

, 30 )/&

1

2

3

4

5

6

1000

900

800

700

600

500

400

300

200

kg/h

100

RP

,30)/&

H250

SN

58 6

67 7/01 -03

M C

H2 50/RR/ M9/K2/ ESK-Z

C

K25.2

1.45 71

F

CI V 2 5 1.4 571

M D

1997

C2H50H

D

0.9 3

kg /l

V

2. 5

mPa.s

T

2 3.5

C

P

0. 4

MPa

FIA 1025

kg

0

3

6

8

7

2

General

These Instructions are supplementary to the ìInstallation and Operating Instructions IFC 090 K / Fì dated 12/96. The

details given there, in particular the Safety Information, are valid and should be observed. These Supplementary

Instructions provide only additional information for device operation and connection to a PROFIBUS-PA fieldbus.

Attention: Please set the controller to manual mode before changing parameters of the IFC 090.

Items included with supply

In addition to the standard scope of supply, these Supplementary Instructions for the IFC 090 with PROFIBUS-PA

interface, plus a diskette with all available GSD files of KROHNE devices.

Software history

Issued

Signal converter

User program

Instructions

month/year Hardware

Firmware

Hard-

ware

Operating

system

Soft-

ware

Device

User

program

09/98

PROFIBUS-

PA Module

1.00

12/96+Supplement

01/99

05/99

PROFIBUS-

PA Module

2.00/990505 PC

Windows 95,

98, NT 4.0

PDM

≥

V 4.1.1

12/96+Supplement

05/99 + 08/99, 03/00

07/00

PROFIBUS-

PA Module

2.00/

PC

Windows 95,

98, NT 4.0

PDM

≥

V 4.1.1

12/96+Supplement

07/00

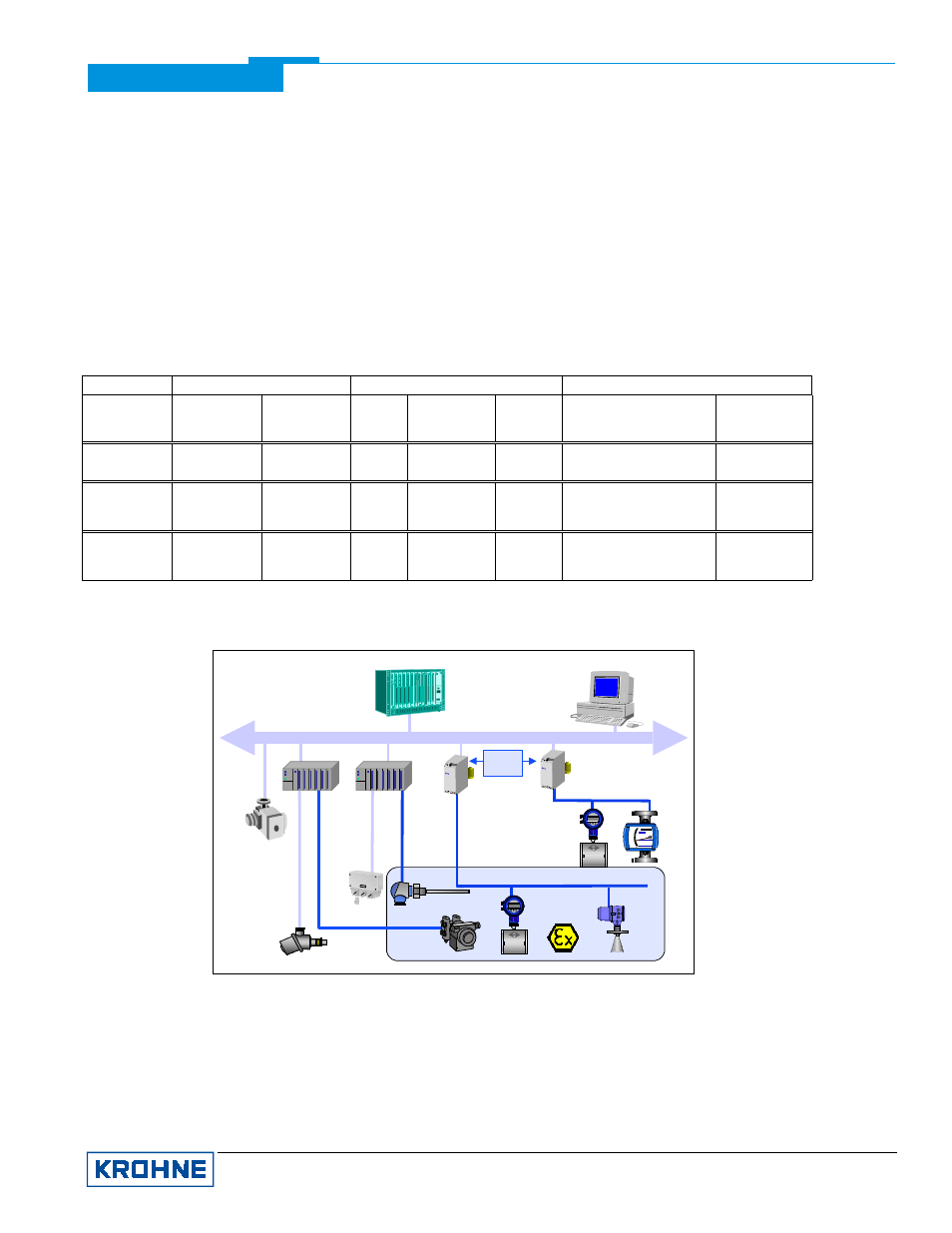

1. PROFIBUS-PA

The above diagram shows a typical instrumentation with PROFIBUS-PA devices in hazardous and non-hazardous

locations, including connection of conventional devices (e.g. with 4-20mA signals) to the PROFIBUS-PA. The

PROFIBUS-PA is normally connected to a segment coupler which, among other things, carries out conversion to the

PROFIBUS-DP. Here, it needs to be noted in particular that the segment coupler is normally set to a fixed baud rate

on the DP side.

Further information on the planning and operation of PROFIBUS-PA networks is to be found in the KROHNE

brochure ìPROFIBUS-PA networksî.