KROHNE OPTISWITCH 5200C Contactless EN User Manual

Page 14

When used in adhesive and viscous products, the tuning fork

should protrude into the vessel to avoid buildup. For that

reason, sockets for flanges and mounting bosses should be

avoided when mounting horizontally.

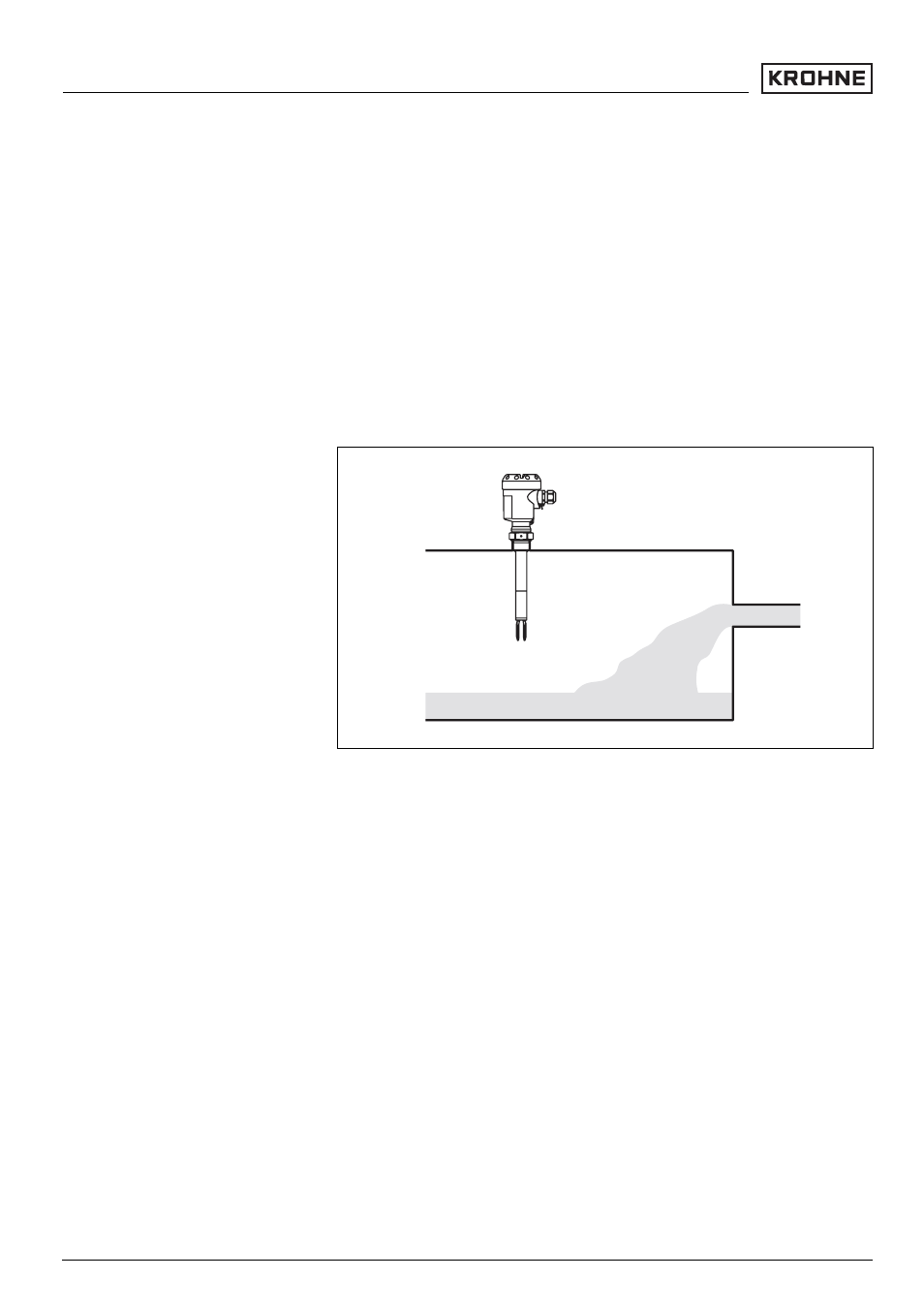

If OPTISWITCH 5200 C, 5250 C is mounted in the filling

stream, unwanted switching signals may be generated. Mount

OPTISWITCH 5200 C, 5250 C at a location in the vessel

where no disturbing influence from e.g. filling openings,

agitators etc. can occur.

This applies particularly to instrument types with long

extension tube.

Fig. 8: Inflowing medium

To minimise flow resistance caused by the tuning fork,

OPTISWITCH 5200 C, 5250 C should be mounted in such a

way that the surfaces of the blades are parallel to the product

movement.

Due to agitators, vibrations or similar, the level switch can be

subjected to strong lateral forces. For this reason, do not use

an overly long extension tube for OPTISWITCH 5200 C, 5250

C, but check if you can mount an OPTISWITCH 5100 C,

5150 C level switch on the side of the vessel in horizontal

position.

Extreme vibration caused by the process or the equipment, e.

g. agitators or turbulence in the vessel can cause the extension

tube of OPTISWITCH 5200 C, 5250 C to vibrate in resonance.

This leads to increased stress on the upper weld joint. Should

Inflowing medium

Flows

Agitators

14

OPTISWITCH 5200 C, 5250 C - with contactless electronic switch

Mounting

30433

-EN

-060831