Appendix, 2 order code for process connection – KROHNE OPTISWITCH 6600 C EN User Manual

Page 24

8

APPENDIX

24

OPTISWITCH 6600 C

www.krohne.com

01/2014 - 4001367704 - MA OPTISWITCH 6600 R04 en

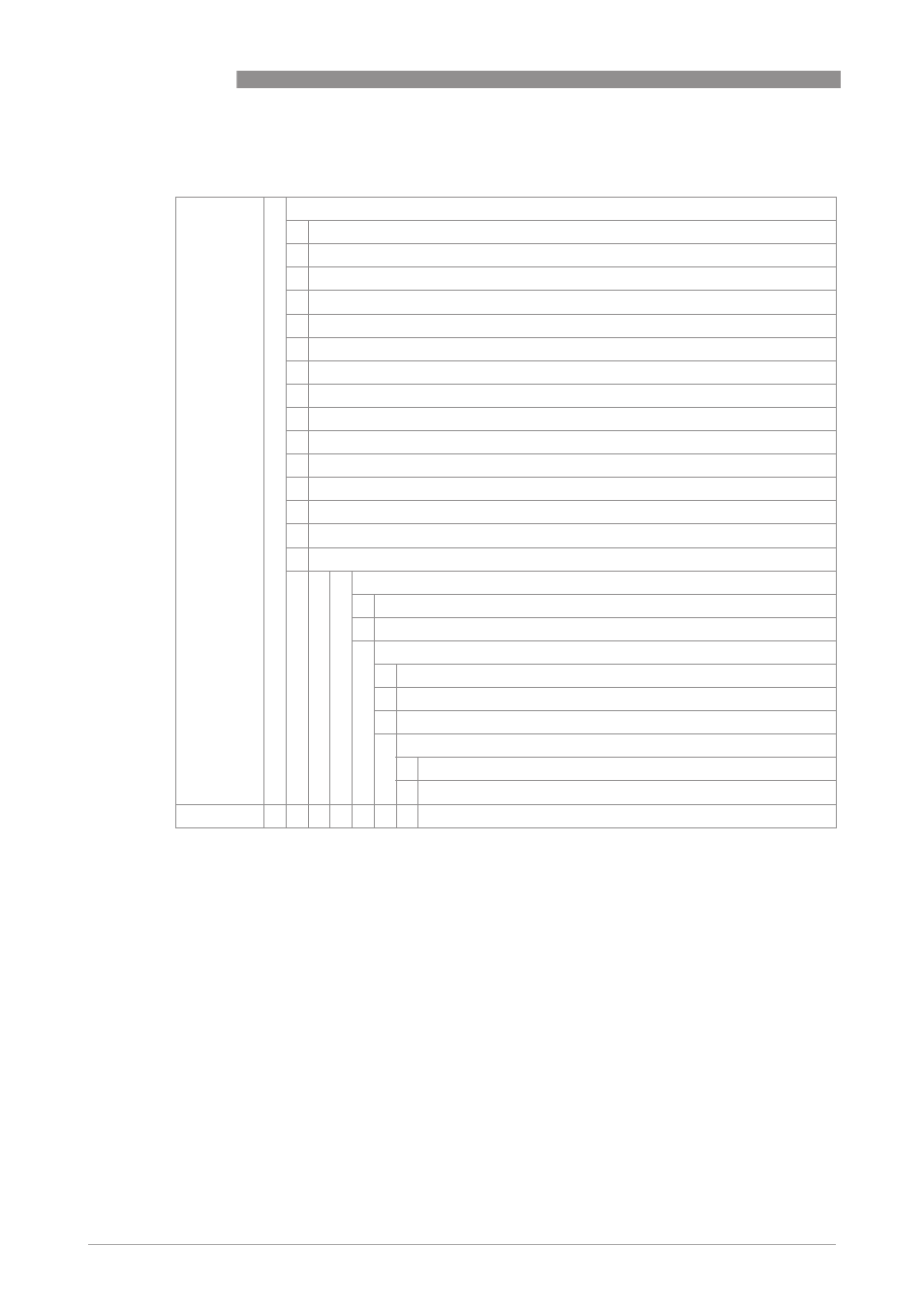

8.2 Order code for process connection

VGP7

4 Process connection type

Process connection type

Process connection type

Process connection type

0 Without

1 Weld-in sleeve; HWN 200

2 Collared weld-in sleeve; HWN 210

3 Weld-in sleeve with shoulder for pipes DN25…50; HWN 220

4 Hygienic adapter for G1 process connection; HGA 200

7 Spherical weld-in sleeve for angled sensor mounting; HWN 250

8 DRD - DN50 sanitary connection; HMM 250

A DIN 11851 - DN25 conical nozzle incl. rotating union nut and gasket; HMT 225

B DIN 11851 - DN50 conical nozzle, incl. rotating union nut and gasket; HMT 250

C Varivent flange type N - DN40/50, incl. "O"-ring; HVF 250

D Tri Clamp 2", DN50 - DIN 32676, ISO 51/40 mm, incl. EPDM seal; HTC 250

U DIN 11851 - DN40 conical nozzle incl. rotating union nut and gasket; HMT 240

V Tri Clamp 1½", DN25/40 DIN 32676, ISO 25/33, 7/38 mm; HTC 240

W SMS adapter 1145 / 51 mm, incl. union nut; HSM 251

Z Allen screw blanking plug; HST 200

Surface

Surface

Surface

Surface

0 Standard

1 Inside electro-polished

Material test / certification

Material test / certification

Material test / certification

Material test / certification

0 Without

1 Material certificate 3.1 (EN 10204)

2 Declaration of conformity 2.1 (EN 10204)

Surface test

Surface test

Surface test

Surface test

0 Without

2 Surface roughness test report EN 10204 2-1

VGP7

VGP7

VGP7

VGP7

4

0 0

Order code