Technical data – KROHNE OPTIMASS 8000K EN User Manual

Page 35

TECHNICAL DATA

6

35

OPTIMASS 8000K

www.krohne.com

08/2010 - 4000921002 - MA OPTIMASS 8000k R02 en

Flanges

• DIN flange ratings are based on EN 1092-1 2007 table G.4.1 material group 14EO

• ASME flange ratings are based on ASME B16.5 2003 table 2 material group 2.2

• JIS flange ratings are based on JIS 2220: 2001 table 1 division 1 material group 022a

Notes

• The maximum operating pressure will be either the flange rating or the measuring tube

rating, WHICHEVER IS THE LOWER!

WHICHEVER IS THE LOWER!

WHICHEVER IS THE LOWER!

WHICHEVER IS THE LOWER!

• The manufacturer recommends that the seals are replaced at regular intervals. This will

maintain the hygienic integrity of the connection.

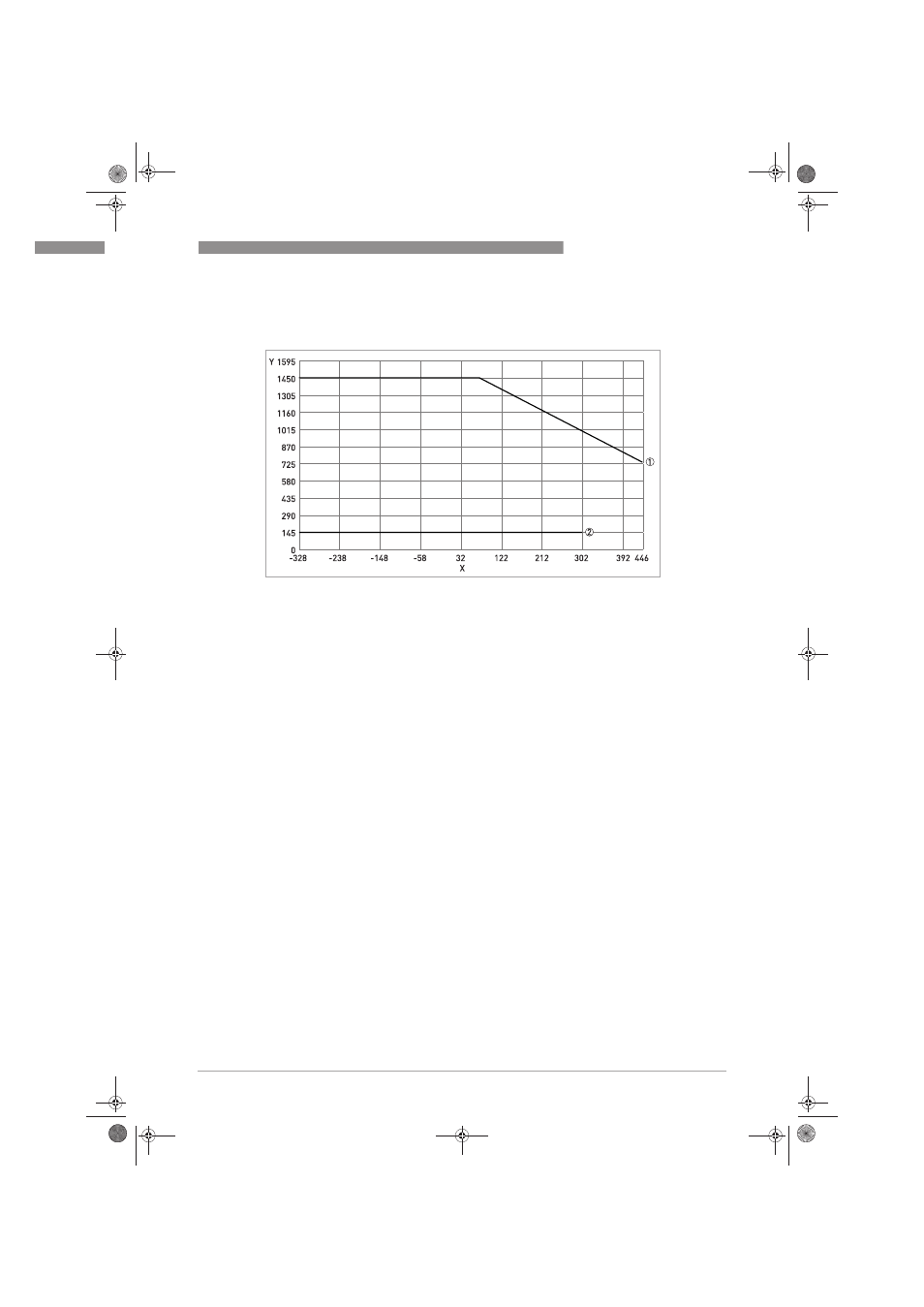

Pressure / temperature de-rating, all meter sizes, in imperial (flanged connections as

Pressure / temperature de-rating, all meter sizes, in imperial (flanged connections as

Pressure / temperature de-rating, all meter sizes, in imperial (flanged connections as

Pressure / temperature de-rating, all meter sizes, in imperial (flanged connections as

per ASME B16.5)

per ASME B16.5)

per ASME B16.5)

per ASME B16.5)

X temperature [°F]

Y pressure [psig]

1 Measuring Tube PED certification

2 Hygienic connection

MA_OPTIMASS_8000k_en_100817_4000921002_R02.book Page 35 Tuesday, August 17, 2010 2:08 PM