INOR LCD-H20 User Manual

Page 2

LIMITED WARRANTY

INOR Process AB, or any other affiliated company within the Inor Group (hereinafter jointly referred to as

”Inor”), hereby warrants that the Product will be free from defects in materials or workmanship for a period

of five (5) years from the date of delivery (”Limited Warranty”). This Limited Warranty is limited to repair

or replacement at Inor’s option and is effective only for the first end-user of the Product. Upon receipt of

a warranty claim, Inor shall respond within a reasonable time period as to its decision concerning:

1 Whether Inor acknowledges its responsibility for any asserted defect in

materials or workmanship; and, if so,

2 the appropriate cause of action to be taken (i.e. whether a defective

product should be replaced or repaired by Inor).

This Limited Warranty applies only if the Product:

1 is installed according to the instructions furnished by Inor;

2 is connected to a proper power supply;

3 is not misused or abused; and

4 there is no evidence of tampering, mishandling, neglect, accidental damage, modification

or repair without the approval of Inor or damage done to the Product by anyone other

than Inor.

This Limited Warranty is provided by Inor and contains the only express warranty provided.

INOR SPECIFICALLY DISCLAIMS ANY EXPRESS WARRANTY NOT PROVIDED HEREIN AND

ANY IMPLIED WARRANTY, GUARANTEE OR REPRESENTATION AS TO SUITABILITY FOR

ANY PARTICULAR PURPOSE, PERFORMANCE, QUALITY AND ABSENCE OF ANY HIDDEN

DEFECTS, AND ANY REMEDY FOR BREACH OF CONTRACT, WHICH BUT FOR THIS PRO-

VISION, MIGHT ARISE BY IMPLICATION, OPERATION OF LAW, CUSTOM OF TRADE OR

COURSE OF DEALING, INCLUDING IMPLIED WARRANTIES OF MERCHANTABILITY AND

FITNESS FOR A PARTICULAR PURPOSE. EXCEPT AS PROVIDED HEREIN, INOR FURTHER

DISCLAIMS ANY RESPONSIBILITY FOR LOSSES, EXPENSES, INCONVENIENCES, SPECIAL,

DIRECT, SECONDARY OR CONSEQUENTIAL DAMAGES ARISING FROM OWNERSHIP OR

USE OF THE PRODUCT.

Products that are covered by the Limited Warranty will either be repaired or replaced at the option of

Inor. Customer pays freight to Inor, and Inor will pay the return freight by post or other “normal” way of

transport. If any other type of return freight is requested, customer pays the whole return cost.

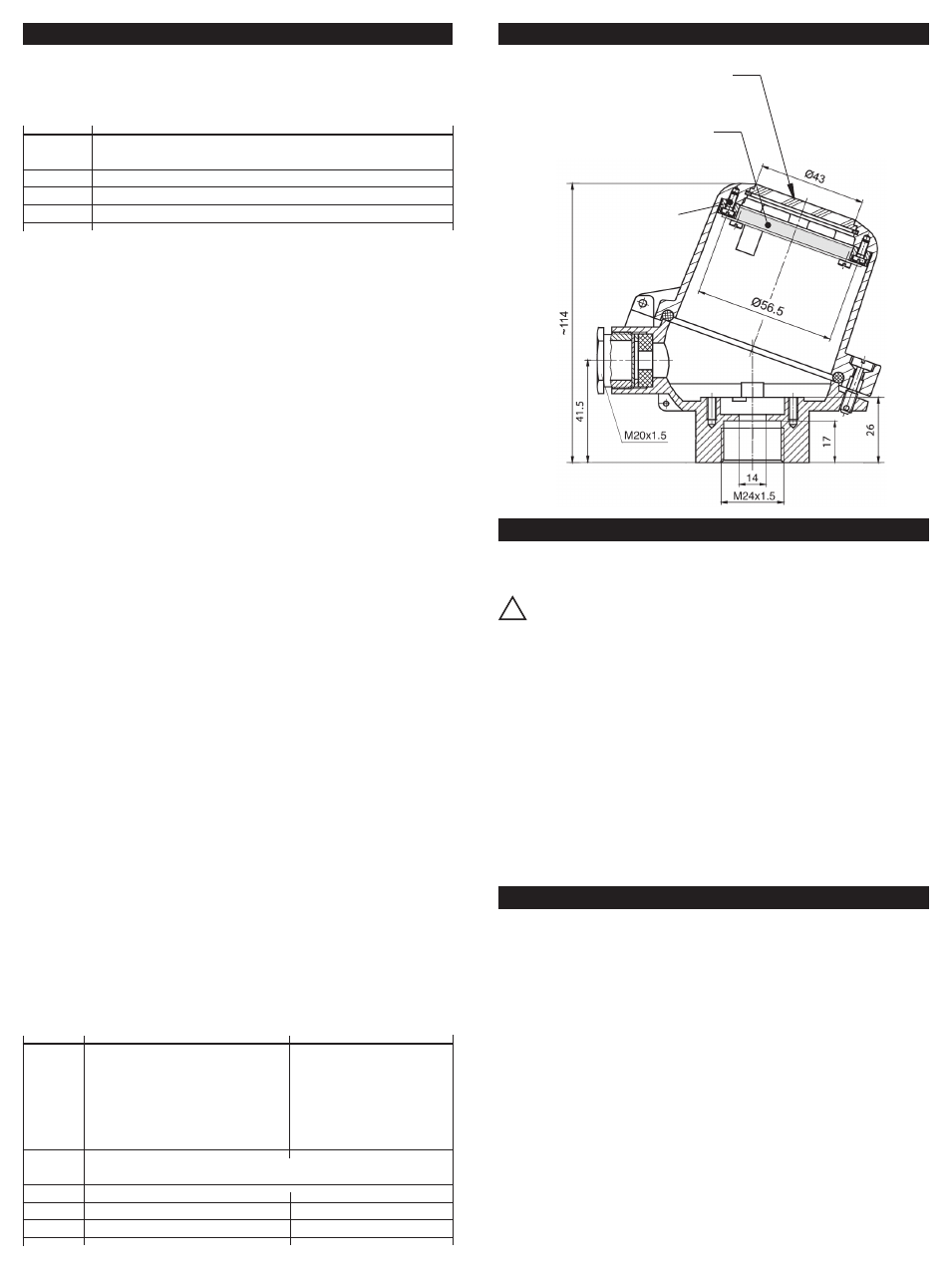

MOUNTING/DIMENSIONS CONNECTION HEAD

Programming: The programming is executed through 3 keys

mounted on the bottom of the display. The central key is the Enter

(F) key. The lateral keys act as the up

and down

digit; they

also act as selec tion of the parameters.

!

CONFIGURATION

Key

Function

F

Access to the programming; move to the following parameter menu;

saving of data and close of the programming

Decreasing digit; selection/set-up of a parameter

Increasing digit; selection/set-up of a parameter

+

“Escape”

Operation: Press the key F for more than 3 seconds to get access to the

programming procedure. The dis play will visualize the “dP” function, which

is the first programming section: Decimal Point. By pressing the

(increase)

and (decrease) keys it’s possible to scroll all the other programming win-

dows. At the end of the programming phase the modified parameters are

stored automatically and retained also during the switch off of the instru-

ment.

Programming procedure:

Set-up of the decimal point (dP)

Press the or

keys to select the decimal point position (from zero to 3

decimals). Press F to confirm. Default = 1 decimal

Set-up of the engineering value related to the zero point (ZErO)

Press the or keys to select the engineering value zero (-1999 to

9999). Press F to confirm. Default = 0.0

Set-up of the engineering value related to the span range (SPAn) Press

the or keys to select the engineering range value (-1999 +9999).

Press F to confirm. Default = 100.0

Set-up of the limit on the input current (Li) This parameter allows to

select the over-load limit of the visualization.

If Li = 0, when the current overcomes the 20 mA value, the display will indicate

the OverLoad mes sage OL (-OL when the current is lower that 4 mA).

If Li = 1, the visualization will be extended of a 10% over the 4...20 mA

range, before indicating the overload. In both cases, overcoming the display

maximum readings (-1999 +9999), the over load message will be indicated.

Default = 1

Set-up of the filter (FiLt) When the 4...20 mA is disturbed it is possible

to select an higher value of FiLt in order to get a more stable and clear

visualization on the display.

Press the key to increase the filter value on the input and the key to

decrease the filter value.

It’s possible to set-up different values from 1 to 8; when FiLt = 1 no filter is

applied on the input and the digital reading occurs every 250 ms.

In this case the updating period of the display will be 250 ms multiplied by

the FiLt value. Example: if FiLt = 5 the updating period of the display will be

1.25 s. Default = 2

Set-up of resolution (riS) This function allows to set-up the resolution

of the display; when riS = 1 the display will indicate all the available digit in

the scale, within the programmed range.

When riS = 2 the steps between two consecutive readings will be doubled:

with riS = 2 it will not be possible to indicate odd numbers.

Selectable values for riS are: 1, 2, 5 and 10.

It is suggested to increase the resolution only if the set range is very large

(example 10000 points) and/or if the 4...20 mA signal is quite unstable: on

the contrary the maximum resolution is normally used. Default = 1

Summary

Key

Function

Disply

SCROLL

Set-up of the decimal point

DP / 000.0

or

Set-up of the engineering value ZERO ZErO / 0.0

Set-up of the engineering range SPAN SPAn / 100.0

Set-up of the OverLoad Limit

Li / 0

Set-up of the input Filter

FiLT / 1

Set-up of the Resolution

riS / 1

F

Access to enter the programming window. Allow to exit the

programmimg window and to save the modifications.

Increasing digit

0 to 9

Decreasing digit

9 to 0

+

Exit the programmimg without saving

CALIBRATION

By pressing contemporary the

+

keys for more than 3 s, it is possible

to access to the cal ibrating function where it is possible to calibrate the zero

and the full scale of the A/D converter of the digital indicator.

Entering this procedure and modifying the parameters will change

the factory cal ibration data. This function must be executed by spe-

cialised personnel only by using adequate instrumentation. A wrong calibra-

tion will affect the right functionality of the instru ment itself.

Step 1: Zero-point calibration

Inside the calibration window, select the ZERO point calibration (C4) by

pressing

or

keys. Apply a 4 mA current to the instrument, wait for the

stabilization of the signal and of the indication and press the key F until the

indication CAL will appear on the display. After few seconds, the new engi-

neering ZERO value will be indicated.

Exit the Zero-point calibration by pressing

+

keys together and proceed

with the Full Scale calibration.

Step 2: Full scale calibration

Inside the calibration window, select the Full Scale calibration (C20) by

pressing

or

keys. Apply a 20 mA current to the instrument and pro-

ceed as for the Zero-point calibration.

Window

(polycarbonate)

LCD-H20

Mounting kit

KDST1