Detcon H2S RoughNECK User Manual

Page 9

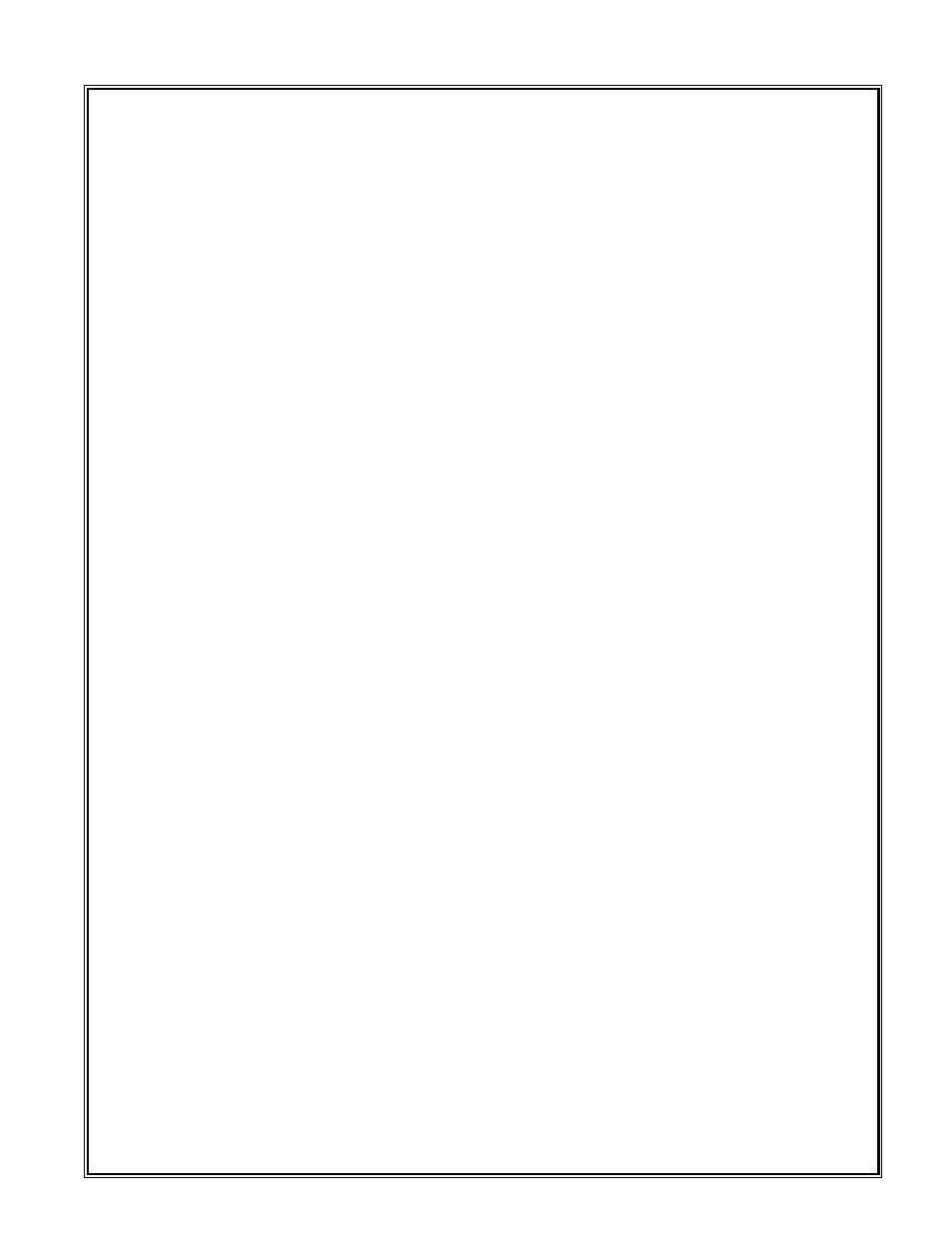

Calibration Table

Each 1 ppm increase in H2S gas will increase the signal by 40 millivolts from a baseline of 1 volt. Below is a

sample of gas concentrations and the correct signal output they will provide.

PPM

V DC

0

≤1

10

1.4

20

1.8

30

2.2

40

2.6

50

3

60

3.4

70

3.8

80

4.2

90

4.6

100

5

g) If applicable, repeat the procedure for sensor #2. Use signal test points TP15 (+), TP16 (–), and Span pot

#2 for adjustment.

7.1 C

ALIBRATION

F

REQUENCY

In most applications, monthly intervals will assure reliable detection. However, to insure optimum reliabil-

ity, it is recommended that the sensors be calibrated each time the job location is changed.

8.0 H

EATER

V

OLTAGE

A

DJUSTMENT

Each sensor is pre-calibrated and tested prior to shipment. The heater voltage is set to 5.2 volts. This tem-

perature is referenced to 72° F ambient. Slight variations in heater voltage will occur in higher or lower

ambient temperatures. Maximum deviation is + or – 5% of original value. For a sensor rated for 5.2 VDC @

72 degrees, the temperature offset at 100 degrees should not exceed –.25 VDC; @ 32 degrees, + .25 VDC.

The nature of the heater function is such that a lower voltage will cause a slower, but more stable response

to gas, while a higher voltage will cause a slightly quicker response. If it should become necessary to ele-

vate heater voltage to maintain response and clearing characteristics, do not exceed 5.5 volts in any temper-

ature range. Note that any adjustment to the heater voltage will require that the sensor be recalibrated with

H2S gas.

The heater voltage is adjusted via the “HEATER” potentiometer and is measured at the two test points

labeled “HEATER”.

Optional Heater Power Adjustment Instructions

A new feature included with the latest revision of Detcon’s proprietary solid state H2S sensor allows for a

more accurate adjustment to be made to the sensor heater circuit. This feature is based on power rather

than voltage. Setting the sensor heater voltage, as measured at the “HEATER” test points, is an acceptable

method. However, the new power feature is an option that allows the user to calculate and implement a

more precise method of temperature control to the sensor over longer periods of service. After several

months and even years, of service the sensor heater film may degrade and require more precise power

level adjustment.

The main objective of the sensor heater circuit is to elevate the temperature of the solid state sensor ele-

ment to between 500 and 527°F. This temperature provides the best combination of speed and stability for

detecting H2S gas. Because the sensor heater resistance increases with age, the power being applied to the

sensor changes even if the heater voltage remains constant. This change in power also changes the sensor

temperature. Thus, a constant power being applied to the sensor will render better performance than a con-

stant voltage.

The desired power setting which is measured in milliwatts, will vary depending on ambient temperatures.

Detcon RoughNECK™ H2S Gas Detection & Alarm System PG.9